| Model: | HAO-100L |

|---|---|

| Brand: | Huaao |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Other Electrical & Electronic |

| Label: | degassing vacuum , mixing device , apg clamping machine |

| Price: |

US $10000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:31 Aug, 2017 |

1.Electronic vacuum gauge more precision

2. Triple safety design

3. Oil cycling heating surround pot, heated evenly

4. Thin film De-gassing, excellent vacuumize

5. Adopt frequency motor to control mixing speed, quick degassing, uniform mixing

6. Compact structure, less space, flexible use.

7. The temperature control system has functions of temperature display, automatic temperature limiting, safety protection and so on

8. Use stirring and injection vehicle directly, this is convenient to use

Packaging & Delivery

| Packaging Details | China maker thin film degassing epoxy resin casting injection machine is packaged with plastic film and wooden case. |

|---|---|

| Delivery Time | Shipped in 45 days after payment |

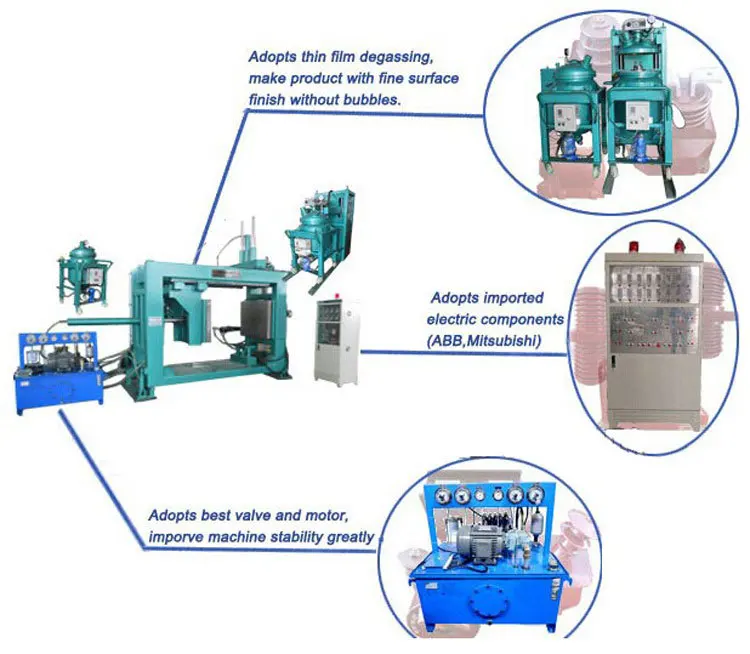

China maker thin film degassing epoxy resin casting injection machine APG-865

Product Description

It is large and medium-sized equipment, dimension of clamping plate is 800*600mm,length of upper and lower core-pulling stroke can be determined according to the product.

It is mainly used for transformer, 12KV-1250A, contact box, 40.5KV bushing, bending plate, upper and lower shell of SF6 insulating cover, etc

Main Technical Parameters

|

Serial No. |

Item |

Technical Parameters |

|

1 |

Model |

APG-865 |

|

2 |

Clamping plate |

800*600mm |

|

3 |

Upper and lower core-pulling stroke |

500mm,350mm |

|

4 |

Mould clamping force |

200KN |

|

5 |

Mould clamping speed |

3.2m/min |

|

6 |

Max mould clamping distance |

1300mm |

|

7 |

Min mould clamping distance |

250mm |

|

8 |

Power of hydraulic station |

5.6KW |

|

9 |

Heating power |

12KW |

|

10 |

Inclination angle of complete machine |

Vertical 0~5° Horizontal 0~ 5° |

|

11 |

Weight of complete machine |

4800KG |

|

12 |

Mould-filling weight |

2.5T |

|

13 |

Outline dimension |

3700*1200*3030mm |

Standard Accessories

The main machine+Mixing device+ Stirring rack+Hydraulic Oil Pump+ Power distribution cabinet+Oven.

Machining Process