| Model: | FS85 100 130 |

|---|---|

| Brand: | Fangsheng |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | plastic granulator , granulating machine , granulator |

| Price: |

¥30000

/ set

|

| Min. Order: | 1 set |

| Last Online:31 Jul, 2017 |

Granulator

Waste water drinking bottles recycling granulating machine

Product Description

With different designs of screw,this machine can be applied to granulate the recycled material of rigind HDPE,PET.PC and other material.It can be stopless in the course of production.It uses pneumatic conversion and strong wind blowing,with water cooling,dewatering machine.At the same time can adjust stainless steel storage container and can run at high speed for along time while extrude stably.

Advantages

1. High-efficient force-feeder ensures high capacity feeding, low energy consumption

2. Single screw extruder, equipped with specially designed screw & barrel, venting system, has a very good output capacity.

3. Pelletizing style: water-ring cutting with extrusion mould, even cutting ensures good shape.

4. Auxiliary machine: pellets cooling & classifying.

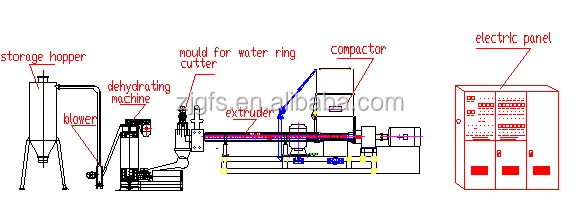

Workflow

|

FS series double-stage pe pp film compactor-granulator machine (with agglomerator) |

|||||

|

Model |

FSDJ-85/85 |

FSDJ-100/100 |

FSDJ-130/130 |

FSDJ-160/160 |

FSDJ-180/180 |

|

Screw Dia.(mm) |

85 |

100 |

130 |

160 |

180 |

|

L/D Ratio |

25-42 |

25-42 |

25-33 |

25-33 |

25-33 |

|

Output(kg/hr) |

120-180 |

250-350 |

400-500 |

550-700 |

800-1000 |

|

FS series single-stage pe pp film compactor-granulator machine (with agglomerator) |

||||||

|

Model |

FSSJ-70 |

FSSJ-85 |

FSSJ-100 |

FSSJ-130 |

FSSJ-160 |

FSSJ-180 |

|

Screw Dia.(mm) |

70 |

85 |

100 |

130 |

160 |

180 |

|

L/D Ratio |

25-42 |

25-42 |

25-42 |

25-3 |

25-33 |

25-33 |

|

Output(kg/hr) |

120-180 |

180-250 |

250-350 |

400-500 |

550-700 |

800-1000 |

vThis is just for your reference.special products and configs are on the basis of maierial.

&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&

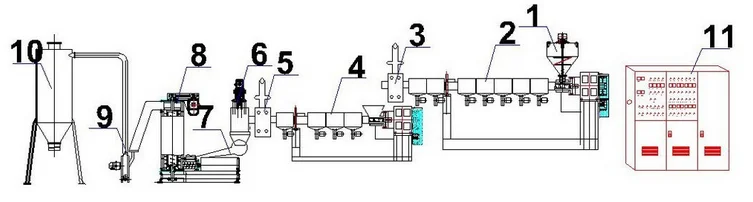

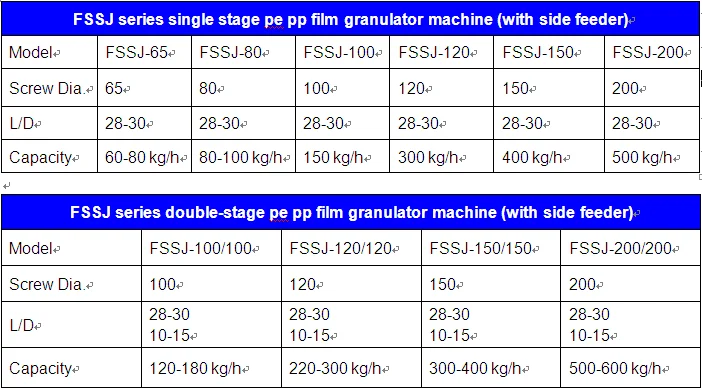

FSSJ series plastic PP PE film/bag pelletizing line/granulating machine(with side feeder)

&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&&

FSSJ150/150 side feeder PP PE granulating line/Pelletizing machine

|

NO. |

Name |

QTY |

Motor Power (KW) |

|||||

|

1 |

Side feeder |

1 |

5.5 |

|||||

|

2 |

Main extruder |

1 |

75+10*6 |

|||||

|

3 |

Secondly screw extruder |

1 |

37+2.2+7*6 |

|||||

|

4 |

Cooling tank |

1 |

- |

|||||

|

5 |

Blower |

1 |

|

|||||

|

6 |

Cutter |

1 |

5.5 |

|||||

|

7 |

Blower conveying system |

1 |

4 |

|||||

|

8 |

Electric panel |

1 |

- |

|||||

|

Double-stage pelletizing line |

||||||||

|

Model |

Power (kw) |

Screw Diameter (mm) |

L/D |

Capacity (kg/h) |

||||

|

SJ150/150 |

205 |

150 |

150 |

25 |

15 |

250-350 |

||

vThis is just for your reference.special products and configs are on the basis of maierial.

Details

Certification

Our Services

• Delivering the goods on time.

•We provide 12-24 months warranty after goods arrive, we respond your complain within 48hours.

•We promise all spare parts available in lifetime use.

•We are a sales team, with all techinical support from engineer team

Packaging & Shipping

Company Information

Jiangsu Fangsheng Machinery Co., LTD. is the professional manufacturer for all kinds of plastic machines which is a blend of researching and developing,designing,manufacturing and operating. We are expert for manufacturing waste plastic recycling machinery,plastic extruder and their auxiliary machines. Our products are mainly exported to American, British, Germany,Russia, Brazil, Australia, Ukraine, The Czech republic, Poland, Saudi Arabia, Mexico, Ecuador, Philippines, India, South Africa, Ghana, Tanzania, Malaysia, Egypt, Japan, Indonesia, New Zealand Vietnam etc.countries and areas.

Exhibition

FAQ

1. Are you manufacturer or trading company?

Answer: we are manufacturer,all the machine ,we make it ourself to reduce the cost of our customer.

2. The quality of the machine is good?

Answer: All the machines are manufactured with high quality, we choose our material very strict,

all the material come to our factory must pass the test. Substandard goods are returned to the supplier.

3. Why choose us?

Answer: That is a frequent question,we take strong attention to every detail in the manufacturing process,the quality control in our factory is very strict,all defective semi-manufactures must be treated again or reject.