| Model: | - |

|---|---|

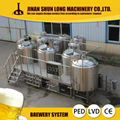

| Brand: | shunlong |

| Origin: | Made In China |

| Category: | Agriculture & Foods / Beverages / Alcohol |

| Label: | beer brewery , brewing equipment , beer fermenter |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:26 Jan, 2018 |

1 company

We company has its own production plant, production and sales integration, for demestic and foreign sales. We can provide customers with high quality equipments and service and cheap price,Please rest assured.

2 product

material our products use is all food grade stainless steel 304.

Thickness: inner3mm outer2mm

Control: semi-automatic/ automatic

Manhole: side /top

Welding: TIG no dead corner welding

Inner Polishing: 0.4um

Capacity: according to customers’ demand, all kinds of sizes

OEM: We can customize products according to customers’ specific demand

Insulation material: polyurethane insulation

Cleaning system: CIP or comprehensive cleaning ball

Type: turnkey or customerized

Application: brewpub/ bar/ restruant/ home

Operation: automatic

It divides into crush system, Saccharifying system, fermenting system, cooling system, controlling system,washing system.

Pipe welding

1,Argon tank welding of L tank in fermentation tank,

2,Single sided welding, double sided forming.

3,Welding lines without oxidation slag, more pressure bearing capacity.

4,One-off molding

Advantages

1. the tank is made of glass manhole to observe the saccharification degree of wort in the tank.

2., the equipment adopts steam heating, equipped with steam safety valve, outdoor exhaust.

3. motor type is horizontal ABB motor

4. wort pump, farm knife and mixing are controlled by frequency conversion, which is convenient for users to operate

5., the use of centralized control valve array, the way of operation is more convenient.

6. the tank is internally subjected to pickling and passivation.

7. filter tank adopts full milling screen plate, thickness 4mm. The filtering effect is better, and the sieve plate is not easy to change.

8. 、 welding seam is smooth and beautiful.

9., the use of double-sided pipeline welding double-sided molding technology.

10. using dual temperature control, PT100; bimetallic thermometer. Temperature control is more accurate

11. 、 yeast adding tank adopts flange pressure manhole, no blind angle, easy to clean.

12. equipped with annular washing and washing machine, it can improve the washing efficiency without damaging the wheat lees.

13. tank equipped with Xuan Shen Xuan Shen tangent, Xuan Shen effect is better.

14. heat exchanger adopts two-stage six lead to increase heat exchange efficiency.

15., with anti-skid design of the operation platform, more humane.

16., with a broken hopper, easy to out of bad.

17. equipped with graduated liquid level to observe tank level.

18., saccharification system is equipped with independent control cabinet.

3 service

Pre-service

Our market team can serve you in 24 hours, so please feel free to contact at your convinent.

Our dedicated engineers can supply 2D,3D drawing for you if you needed.

If you need to inspect our factory, we can book the hotel and make the invitation letter for you.

Our market team with our engineer with more than 10 years experiences together can satisfy you with

any technology problem;

Customize machine can be offered(voltage,material,dimension,heating source and so on)

After-service:

When shippment, we will supply a whole set of parts for backup.

If there is any parts damaged, we are surely can send the part to you in 24 hours.

Main machine is 3 years warranty, auxiliary machine is 12 months warranty,

electrical components is 18 months warranty, life long service.

4 packing

Wooden case or iron frame case, or packing according to your demand

5 certification

CE PED LVD

6 how to contact me

Email: sales08@slbreweries.com

Telephone: 8615106971735

QQ: 1095090376

Skype: 8615106971735

Wechat: 15106971735

| Payment Terms: | TT |

|---|---|