| Model: | JS 6035-H |

|---|---|

| Brand: | KINGS |

| Origin: | Made In China |

| Category: | Computers & AV Digital / Computer Accessories / Printer |

| Label: | sla 3d printer , industrial 3dprinter , laser 3d printer |

| Price: |

US $95000

/ Set

|

| Min. Order: | 1 Set |

| Last Online:21 May, 2018 |

| Prodcut Description | |

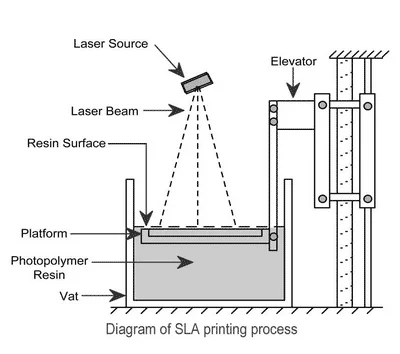

| Working principle of SLA | |

|

SLA process is the most studied,the most advanced and the most widely used method of rapid prototyping in the world (also the rapid prototyping method adopted by our company).SLA technology is the principle of conputer-controlled laser beam scanning on the surface of the photosensitive resin material point by point.The thin resin layer (about a few tenths of a millimeter) in the scanned area produces photopolymerization reaction,which solidifies to form a thin layer of the part.The table down a layer of thickness so that the surface of solidified resin is coated with a new layer of liquid resin.The next layer is scanned and repeated until the whole prototype is finished.Since the photopolymerization is based on light rather than heat,only lower power of laser source are needed at work. |

|

| Comparision between SLA and FDM | |

| SLA | FDM | |

|

Print precision |

can be as fine as 0.1mm,can process any complicated and delicate parts,or the prototypes and moulds which are difficult to be shaped by traditional methods |

about 0.2mm,and it is difficult to manufacture complicated parts |

|

Print size |

Kings®3D printer maximum print size: 850 * 850 * 550,large-scale molds also do rapid prototyping |

generally about 300*300*500,difficult to build large size complicated parts |

|

Print speed |

Kings®3D printer can reach 10m/s,processing speed is high,which shorten production cycle |

the fastest printing speed is only 0.15m/s,prototyping speed is relatively slow,long production time |

|

Printed materials |

Multi-attribute photosensitive resin is available |

Only supports ABS and PLA |

|

Surface finish |

smooth surface,thin wall structure can produce very fine details,post-processing is easy |

feel layered by touching finished products |

| Introduction of equipment |

| SPECIFICATIONS OF JS 6035-H INDUSTRIAL SLA 3D LASER PRINTER | |

| Basic information | |

| Construction Size | 350mm(X)×600mm(Y)×350mm(Z) |

| Apparatus Size(without display): | 8108cm(W)×95cm(L)×198cm(H) |

| Rated Dissipation |

1.5KVA |

| Apparatus Weight: | about 880kg |

| LASER SYSTEM | |

| Laser Type | Nd: YV04 Solid Laser |

| Wave Length | 355nm |

| Power | Minimum Power to Liquid Level≥300mW |

| COATING SYSTEM | |

| Coating Mode | Intelligent Position Vacuum Recoating |

| Normal Layered Thickness | 0.1mm |

| Rapid Build Layered Thickness | 0.15mm |

| Precise Build Layered Thickness | 0.05mm |

| Special Build Layered Thickness | 0.05mm~0.20mm |

| OPTICAL & SCANNING SYSTEM | |

| Light Spot(diameter @1/e2) | 0.10-0.15mm |

| Scanning Mode | Germanic Galvanometer Scanner |

| Parts Scannin Speed | Maximum 10.0m/s |

| ELEVATOR SYSTEM | |

| Vertical Resolution Ratio | 0.0005mm |

| Repeat Positioning Accuracy | ±0.01mm |

| RESIN TANK | |

| First TankWeight | about 70kg |

| Forming Material | Photosensitive Resin |

| Resin Heating Method | Bottom Heating with Silicone Rubber |

| CONTROL SOFTWARE | |

| Machine Control Software | KING3D Control Software |

| Device Software Interface | 3D Design Software,STL File Format |

| SOFTWARE SYSTEM | |

| Master Controller Operation System | Windows 7 |

| Network Type and Protocol | Ethernet,TCP/IP |

| INSTALLATION CONDITION | |

| Current Source | 200-240VAC 50/60Hz, Single Phase,10A |

| Ambient Temperature | 20-26oC |

| Relative Humidity | <40%,Frost Free Knot |

| Variable spot techonology:automatically adujust the laser power therough the kings control software .when the printer scanning system is scanning the internal and external contours,the laser use different power to form a spot with diferent diamerers.

Advantages:the laser power increases automatically when the internal structure is filled,the spot diameter becomes larger,and the printing speed increases.When printing an external profile,the laser power is automatically adjusted to decrease,the spot diameter becomes smaller,and the printing speed is normal.The overall printing speed increases,the surface fineness is better |

|

Kings control software You can monitor the printing progress,print time and print speed through the screen.

|

|

Materials Jinshi research and development of 3D printing materials in the international advanced level,including hard material,soft material,color material with high temperature resistance,high toughness,high strength,flexibility,transparency and other characteristics,to meet the different industries on the physical properties of 3D printing produtcs,so as to achieve the perfect final product presentation. |

Material properties table

| Name | Hardness shoer D |

Tensile strength (Mpa) |

Tensile modulus (Mpa) |

Elongation break (%) |

Flexural strength (Mpa) |

Flexural modulus (Mpa) |

Izod impactnotched (J/M) |

Heat deflection temperature (℃) |

| 9400 | 83 |

27-31 |

2189-2395 |

12-20 |

69-74 |

2692-2775 |

58-70 |

50-60 |

| 2015T | 85 |

45-50 |

2500-3720 |

4-9 |

70-80 |

2400-2600 |

20-27 |

80-90 |

| lasty | 88 |

40-58 |

2511-2665 |

11-16 |

71-76 |

2495-2565 |

30-40 |

60-70 |

| YGH1001 | 82 |

50-58 |

2300-2500 |

15-25 |

60-70 |

2700-2950 |

25-35 |

85-95 |

| Print abilitiy |

| Kings 3D printer | Time | Maximum consumption of raw materials(Grams) |

| KINGS3053-H | 24H | 1500-1800 |

| KINGS4500-H | 24H | 1800-2100 |

| KINGS6035-H | 24H | 1800-2300 |

| KINGS6000-H | 24H | 1800-2500 |

| KINGS8000-H | 24H | 2800-3300 |

| KINGS7255-H | 24H | Doube laser 4800-6500 |

| KINGS8500-H | 24H | (sign laser 2800-3500) Doube4800-6500 |

|

Print accuracy High precision,the size error of the product structure is ±0.1mm.

|

|

Apperance Smooth surface,delicate,structured.

|

|

Post-processing 1. Remove the support structure

|

|

Application area Kings 3D series equipment not only is the first choice of rapid prototyping of car,building,light fixture,toys,mobile phone,medical,fashion,art and industry,but also a wise choice for shoe mold and other complex process of mold industries.

|

|

Requirements of installation environment 1.Print workshop should be protected from light,using soft yellow light. 2.Workshop is clean and no dust. 3.The temperature (20-25°) standard is 23°,air humidity 35% -40%,keep ventilated. 4.The printer should far away from vibration source. 5.Voltage is 220V,air conditioning socket must use 16A,printer and oven must use 10A, must be ground wire. 6.Air conditioning requirements:10m2 output power 5000W,20m2 output power 7500 W,30m2 output power >7500W 7.The heat dissipation sheet metal hole remains unobstructed,exhaust fan cover must be covered. 8.The waste water of the dehumidifier must be drained outside the printing workshop,air conditioning and dehumidifier can not be facing the printer. 9.The washing alcohol is placed in the washing room and can not be in the same room as the printing workshop. 10.Photosensitive resin material should be used frequently. Certification

|

|

After-sale service and service instruction 1.1After-sales: We arrange our technical staff in 30 working days to provide global technical after-sales service.

|

| Company Profile |

|

Shenzhen Jinshi 3D Printing Technology Co.,Ltd. is a high-tech enterprise.We devote ourselves to providing professional solutions of rapid manufacturing for customers in various industries based on the 3D digital manufacturing technology through integrating professional resources worldwide in the field of rapid manufacturing.The services include the equipment in the area of rapid prototyping RP,rapid tool RT and reverse engineering RE,various professional rapid processing software,rapid manufacturing integration system,the research and development of rapid prototyping material photosensitive resin,the design and production of various types of rapid prototyping model.

|

|

About payment 1.Shipping terms FOB/EXW: 50% deposit inadvance,the balance should be paid before shipment. 2.Payment terms: T / T;Onetouch;international Alipay

|

| Packing & Delivery |

| Shipping list |

|

3D printer |

1 |

laser |

1 |

|

scraper |

1 |

Under the platform |

1 |

|

UPS power supply |

1 |

tool case |

1 |

|

allen wrench |

1 |

gloves |

1 |

|

caliper |

1 |

brush |

2 |

|

thermometer |

1 |

clip |

2 |

|

UV curing tank |

Optional |

dehumidifier |

Optional |

|

Package

Delivery method: by sea or by air Delivey time: 30-45 days |

||||

| FAQ |

|

1.Q : Are you a factory or a trading company?

2.Q : What is your max size for CNC prototype and 3D printing? A : For CNC machine,there is no max size but bigger

3.Q : Can you do OEM customization? A : Yes,we provide OEM services. 4.Q : How long will be your delivery time?

5.Q : What information should I give for detailed quotation?

6.Q : Do you only provide rapid prototyping service?

7.Q : How does your facility handle quality control?

|