| Model: | LN-5 |

|---|---|

| Brand: | Lanning |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Filters |

| Label: | oil recycling machin , oil refinery plant , oil distilation |

| Price: |

US $43400

/ set

|

| Min. Order: | 1 set |

| Last Online:29 Jul, 2017 |

Application:

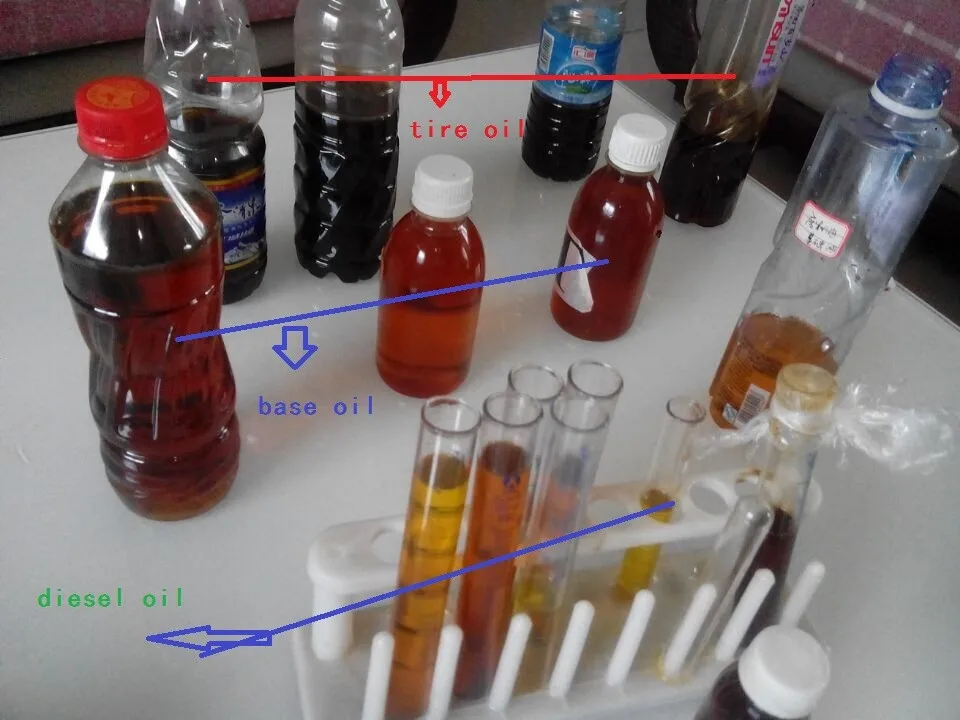

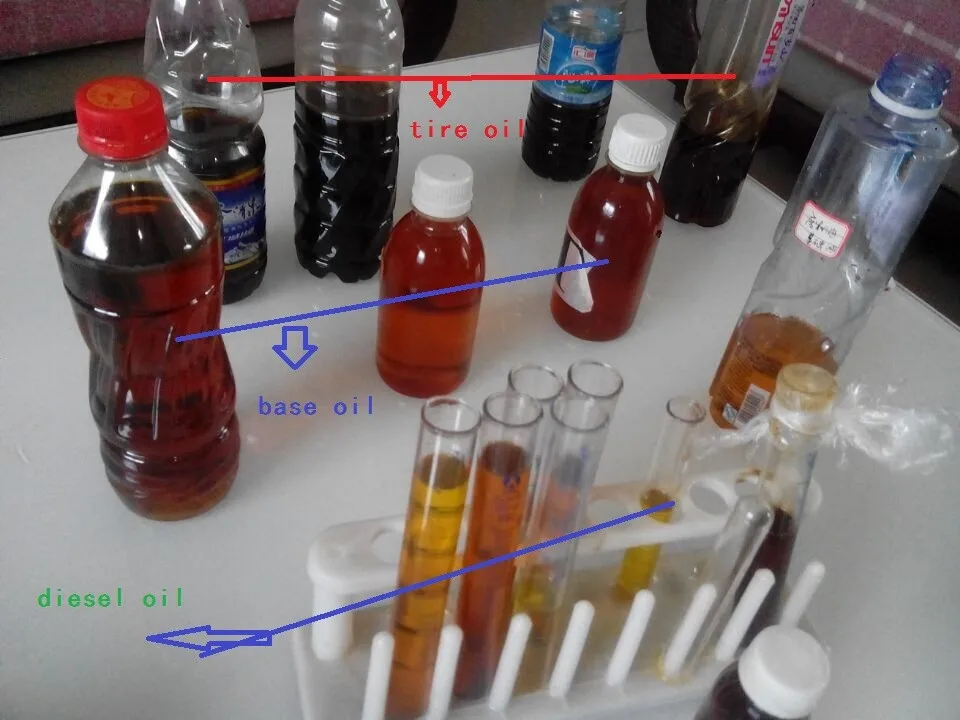

This machine can refine used motor/engine oil, waste crude oil, tyre oil, plastic oil, oil sludge, waste heavy oil to diesel and gasoline.

End products:

Diesel, gasoline, oil residue,base oil

End product usage:

The diesel from waste oil can be used for low speed diesel engine, like Genset, digging machine, road roller, loading machine and ships.

Main models:

| Capacity per batch | model | reactor type | packing (containers) |

| 5 ton | LN-5 | vertical | 2*40' HQ |

| 10 ton | LN-10 | vertical | 2*40' HQ |

| 15 ton | LN-15 | horizontal | 3*40 HQ |

| 20 ton | LN-20 | horizontal | 4*40' HQ |

| 25 ton | LN-25 | horizontal | 4*40'HQ |

| 30 ton | LN-30 | horizontal | 5*40' HQ |

| 35 ton | LN-35 | horizontal | 6*40'HQ |

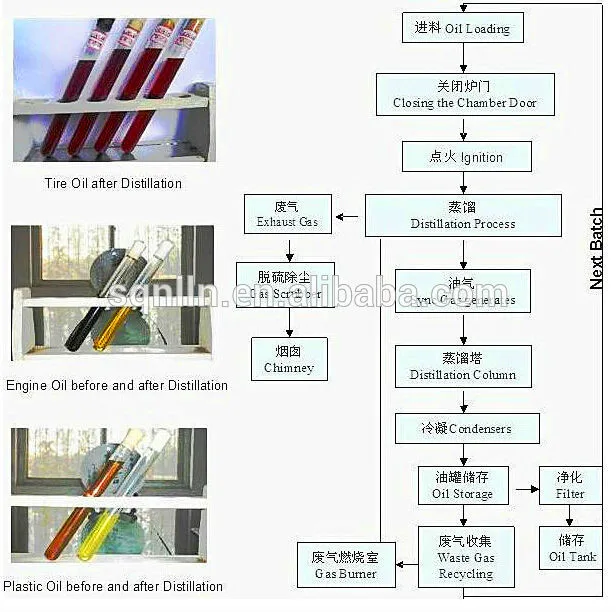

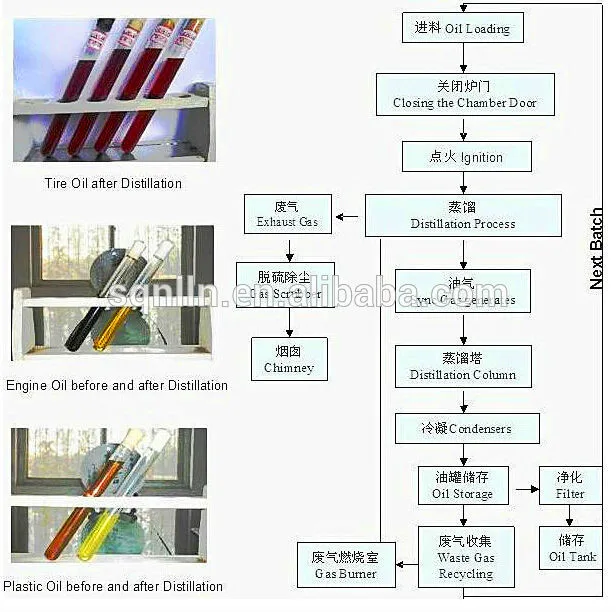

Process Instruction:

Advantage:

1. High oil output: more than 80%.

2. Hot air heating to ensure oil quality and safety

3. Dust-removing device,more environment friendly.

4. Tail-gas recovery system,save energy and ensure safety.

5. Q245R standard boiler plate with unique tracking number..

6. Catalyst formula provided for free.

7. Engineers available to service overseas for free.

8. Competitive price with own factory.

Application:

This machine can refine used motor/engine oil, waste crude oil, tyre oil, plastic oil, oil sludge, waste heavy oil to diesel and gasoline.

End products:

Diesel, gasoline, oil residue,base oil

End product usage:

The diesel from waste oil can be used for low speed diesel engine, like Genset, digging machine, road roller, loading machine and ships.

Main models:

| Capacity per batch | model | reactor type | packing (containers) |

| 5 ton | LN-5 | vertical | 2*40' HQ |

| 10 ton | LN-10 | vertical | 2*40' HQ |

| 15 ton | LN-15 | horizontal | 3*40 HQ |

| 20 ton | LN-20 | horizontal | 4*40' HQ |

| 25 ton | LN-25 | horizontal | 4*40'HQ |

| 30 ton | LN-30 | horizontal | 5*40' HQ |

| 35 ton | LN-35 | horizontal | 6*40'HQ |

Process Instruction:

Advantage:

1. High oil output: more than 80%.

2. Hot air heating to ensure oil quality and safety

3. Dust-removing device,more environment friendly.

4. Tail-gas recovery system,save energy and ensure safety.

5. Q245R standard boiler plate with unique tracking number..

6. Catalyst formula provided for free.

7. Engineers available to service overseas for free.

8. Competitive price with own factory.

Main parts:

1.heating chamber

2.distillation reactor

3.catalyst tower

4.vertical condensers

5. water pond

6.blending tank

7. residue tank

8.oil storage tank

9. water sealing tank

10.de-duster

11.electric control cabinet

12. pressure filter

Package:

For the big reactor, big tanks, no need to packing. For smaller parts, we use wooden box to pack properly, making sure it is safe for loading and unloading.

|

Item |

capacity |

40’ HC container |

40’ FR container |

|

LN-5 |

5 tons/batch |

1 set |

/ |

|

LN-10 |

10tons/batch |

2 sets |

/ |

|

LN-20 |

20 tons/batch |

4 sets |

/ |

|

LN-30 |

30 tons/batch |

6 set |

/ |

Shipping:

Delivery time: 15-20 days after the deposit received

Installation:

For each set of machine, one technical engineer will be sent to your local to guide the installation, commissioning and staff training for free.

FAQ:

1. When will we receive the foundation drawings?

After signing the contract, only then we can design it according to your machine and land.

2. What are the catalyst that we will have to regularly import from China for running the plant?

Don’t worry about the catalyst. We will provide you the catalyst formula for free. It’s very cheap, about 100 RMB for one ton used oil. You can buy them in your local.

3. Total how many people are needed for running the plant?

One or two workers.Because It’s easy to operate the machine since it’s electric control.

The workers don’t need special skills because our engineers will train them.

4. What are the pollution wastes that will be generated in running of the plant?

There is little waste left.

Waste gas: Transferred through two safety device: water seal &burning air nozzle. Fully burnt.

Waste liquid: 50kg process from 1 ton of oil, easy to process). Counteract the liquid

by alkalescent liquid solution.

Waste solid:There are some solid residua left. Its weight may be 5%--10% of raw material.

And the main part is asphalt, which could be sold in the market.

5. How much water will be required daily?

The water is circularly used for the cooling. For the water cost, it is very little.

You put some water in the water tank, then it can be used many days, no need to change. Then if there is some reduction after maybe half month or one month, you just add some. So we don't have data about this.

6. What will be the covered shed size that we need to make?

For the whole plant, you only need to make a shed for the reactor and the workers working area It needs at least 6.5m long*5.7m width*5m height if the chimney is installed outside.

7. How much civil work will be involved?

Three. 1st, the foundation for the reactor base.

2 nd, the water cooling pool if you choose the coil pipe cooling system.

3rd, the oil tank pool.

Contact:

annie

Tel/wechat/whatsapp:+86 18837001682

QQ:960556971