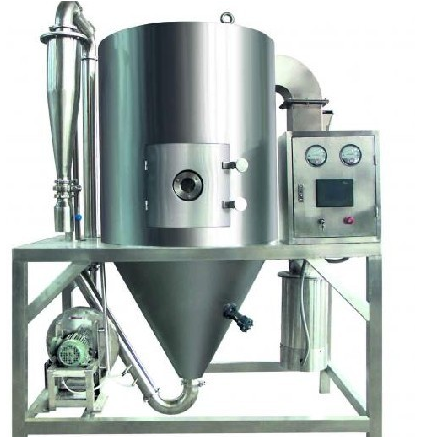

LPG Centrifugal Atomizer Industrial Spray Dryer

Product Description

High SpeedCentrifugal Spray Dryer Spray drying is the technology most widely used in the liquid technology s haping and in the drying industry.The drying technology is most suitable for producing solid powder or particle products from liquid materials,such as:solution, emulsion, suspension and pumpable paste states,For this reason,when the particle s ize and distribution of the nal products,residual water contents, mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technologies. is suitable for producing powder or particle solid products from the raw materials , such as :solution ,emulsion, and paste states.

The uniformity, flow capability & solubility of the dryer are very good. The finished products have high quality and high-purity.

LPG100 High SpeedCentrifugal Spray Dryer is Simple and stable operation, convenient control and deb ing, easy to achieve automatic operation.

Spiral Seaweed Powder (Spirulina micro algae) High Speed Centrifugal Spray Dryer with LPG ,the production process is simple, The dryer can dry the liquid material which contains 40%-60%(90% for special materials) of moisture into powder at once. There's no need for smashing or sieving after drying so the operational environment is clean and in healthful condition, it also can avoid powder flying in the air during drying process.

WORKING PRINCIPLE of LPG Series High-Speed Centrifugal Spray Dryer

Filtered and heated air goes into air distributor on the top of the dryer, and spirals into drying room uniformly. Going through the high-speed centrifugal atomizer on the top of tower, the liquid (rotates) sprays into extremely fine mist liquid beads, and can be dried completely in a short time in co-current contact with hot air. Finished products exhaust continuously from the bottom of the drying tower and cyclone separator, while waste gases are vented by the fan.

TECHNICAL PARAMETERS

Dimension / Model

5

25

50

150

200-2000

Inlet Temperature C

140-350 automatic control

Outlet Temperature C

80-90

Max. Evaporation Capacity (kg/h)

5

25

50

150

200-2000

Atomizing Method

compressed air drive

mechanical drive

Revolution (r.p.m)

25000

18000

18000

15000

8000-15000

Revolution (r.p.m)

Diameter of Atomizing Disc (mm)

50

120

120

150

180-240

Heat Source

electricity

steam+electricity

steam+electricity,oil, oil fuel, hot air furnace

Max. Heating Power (kw)

9

36

72

99

Overall Dimensions(LWH)(m)

1.8x0.93x2.2

3x2.7x4.26

3.5x3.5x4.8

5.5x4x7

depends on actual situation

Dried Powder Restoring Rate (%)

95

http://www.lw-equipment.com

Product Image

Img 1

Img 2

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,