High precision Industry Metal Stamping Parts

Product Description

Stamping is a method of forming a workpiece (stamping part) of a desired shape and size by applying an external force to a plate, a strip, a pipe, a profile, etc. by a press and a die to produce a plastic deformation or separation. Stamping and forging are the same plastic processing (or pressure processing), collectively forging. Stamping blanks are mainly hot and cold rolled steel and steel. The world's steel, 60 to 70% of the plate, most of which finished by stamping. Car body, chassis, fuel tank, radiator film, boiler drum, container shell, motor, electrical iron core steel sheet are stamping processing. Instrumentation, household appliances, bicycles, office machinery, life utensils and other products, there are a large number of stamping parts. Stamping is mainly classified according to process, can be divided into two major categories of separation process and forming process. The separation process, also known as punching, is intended to separate the stamping part from the sheet along a certain contour line while ensuring the quality requirements for the separation section (Table 1). The purpose of the forming process is to cause the sheet to undergo plastic deformation under non-crushing conditions to produce the desired shape and size of the workpiece. In the actual production, often a variety of processes integrated in a workpiece. Punching/bending/cutting/drawing/bulging/spinning/correction is several major stamping process.

Stamping process information

Technology(Stamping)

surface treatment

Metal Material

Bracket stamping parts

electroplating

brass stamping

terminal stamping parts

oxidation

aluminum stamping

metal shield cover

electrophoresis

stainless steel stamping

metal shrapnel stamping

spraying

steel stamping

deep drawn stamping parts

electrolytic

carbon stamping

sheet metal stamping parts

polishing

copper stamping

automotive stamping parts

drilling

alloy stamping parts

Why Choose us ??

1. We have more than 15 years customized-order mechanical parts experience

2. Have our factory can be control quality & delivery time

3. We have our self mold Can be customized you want size and design

4. Can be visit our factory

5. professional company & team & production facility will be More guaranteed,welcome to inquiry or order to us.

6.OEM/ODM custom service ,welcome to send your inquiry & place the order.

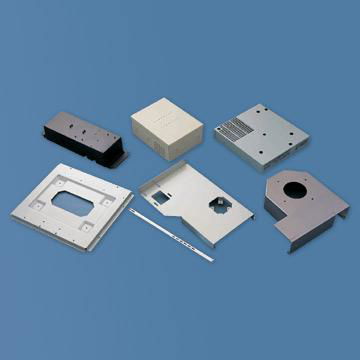

Product Image:

Production Flow:

Certification

FAQ:

Q1. What is your terms of payment?

A: TT/ Paypal/ Western Union .

Small amount 100% TT payment . large amount T/T accept 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2. What is your terms of delivery?

A: EXW, FOB, CFR, CIF,

Q3. How about your delivery time?

A: Generally, it will take 7-10 days sample time. 15 to 25 days after receiving your advance payment. The specific delivery time depends on the items quantity and the quantity of your order.

Q4: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Q5: Your are a trade company or producer?

Our company is factory ,have our self machines,Design, research and development, production.

http://www.dgsymetal.com

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,