Plating threaded spring plunger with pin

Product Description

Lathe processing is part of the machining, there are two main forms of processing: one is to fix the knife, the processing of the unformed workpiece in the rotation; the other is the workpiece fixed, through the workpiece high-speed rotation, turning ( Turret) for lateral and longitudinal movement

The definition of the Threaded Spring plunger Pin

Spring plunger pin, a mold parts for plastic molds precision lock position between the module and

the template to make the mold work smoothly. Spring plunger pin upper and lower positioning block

positioning block irregularities portfolio allocation, according to projections protruding positioning pin

positioning block is divided into different pieces of columns and angled obliquely positioned Spring

plunger pin, oblique Spring plunger pin and angled positioning of the lower end of the column

according to the actual need to use some there is a slot for a more conducive to precise positioning.

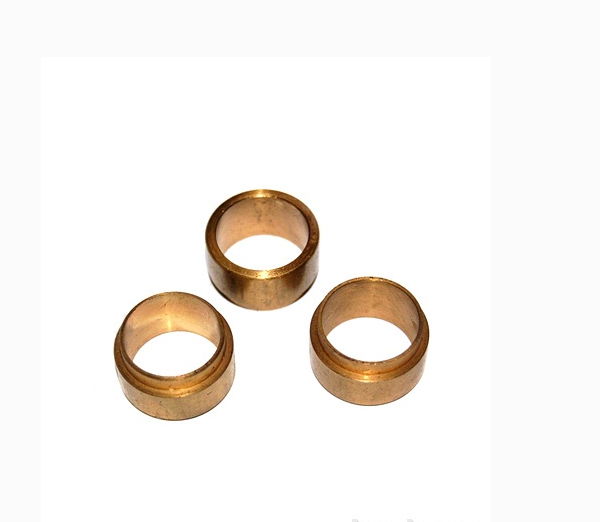

Product Name

Standard Stainless Steel Zinc Plated Retractable Spring Index Plunger With Pull Ring

Material

Steel/Stainless Steel/Aluminum/Copper/Brass/Titanium/Iron

Surface Treatment

Black Anodized/Plain/Nickel Plated/Chromated/Passivated/Zinc Plating/Phosphated, Dacromet/Copper Plating/Gold Plating/Chromated/Hot Deep Galvanized/Tin Plated,etc.

Manufacturing Process

CNC Machining/Automatic Turning/Hardened/Polished/Painted/Electrophoretic Coating

OEM/ODM

We are the professional manufacturers for cnc machining parts/ lathe turning parts.

Salt Spray Time

24 hours,48 hours,96 hours,mostly we would do that based on your requirements,also together with the salt spray checking report.

We provide professional customized-order mechanical parts, including sheet metal stamping parts, sheet metal fabrications parts, CNC milling and turning parts, stamping tool and die, welding and riveting as well as surface treatment like powder coating and plating . Stamping workshop can provide one-stop service from prototypes to rail run, small volume to mass stamping production, and also covers welding ,riveting, tapping and surface treatment.

Product image

FAQ:

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: TT/ Paypal/ Western Union .

Small amount 100% TT payment . large amount T/T accept 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery? A: EXW, FOB, CFR, CIF,

Q4. How about your delivery time?

A: Generally, it will take 7-10 days sample time. 15 to 25 days after receiving your advance payment. The specific delivery time depends on the items quantity and the quantity of your order.

Q5. Can you produce according to the samples?A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?A:1. We keep good quality and competitive price to ensure our customers benefit ;2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Q9: Your are a trade company or producer?Our company is factory ,have our self machines,Design, research and development, production.

http://www.dgsymetal.com

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,