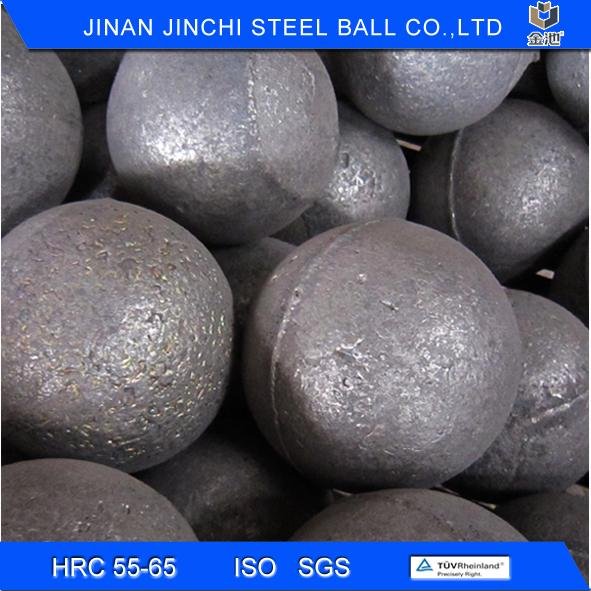

Steel Grinding Balls Cast Steel Balls

Product Description

Chemical composition of Casting balls

| Item |

C |

Si |

Mn |

Cr |

P |

S |

Mo |

Cu |

Ni |

High chrome cast grinding balls

|

ZQCr12 |

2.0-3.0 |

0.3-1.2 |

0.2-1.0 |

11-13 |

≤0.10 |

≤0.10 |

0-1.0 |

0-1.0 |

0-1.5 |

| ZQCr15 |

2.0-3.0 |

0.3-1.20 |

0.2-1.05 |

14-17 |

≤0.10 |

≤0.10 |

0-1.0 |

0-1.0 |

0-1.5 |

| ZQCr20 |

2.0-2.8 |

0.3-1.0 |

0.2-1.0 |

18-22 |

≤0.10 |

≤0.08 |

0-2.0 |

0-1.0 |

0-1.5 |

| ZQCr26 |

2.0-2.8 |

0.3-1.0 |

0.2-1.0 |

22-28 |

≤0.10 |

≤0.08 |

0-2.5 |

0-2.0 |

0-1.5 |

Middle chrome cast grinding balls

|

ZQCr7 |

2.0-3.2 |

0.3-1.5 |

0.2-1.0 |

6.0-10 |

≤0.10 |

≤0.08 |

0-1.0 |

0-0.8 |

0-1.5 |

Low chrome cast grinding balls

|

ZQCr2 |

2.0-3.6 |

0.3-1.5 |

0.2-1.0 |

1.0-3.0 |

≤0.10 |

≤0.08 |

0-1.0 |

0-0.8 |

------- |

| Bainite ductile cast grinding balls |

ZQsi3 |

3.2-3.8 |

2.0-3.5 |

2.0-3.0 |

--------- |

≤0.10 |

≤0.08 |

-------- |

-------- |

------- |

High Chrome Ball Parameter

| Nominal diameter |

Weight of single ball in average |

Quantity/MT |

Surface hardness |

Impact toughness |

| (mm) |

(mm) |

|

(HRC) |

(Times) |

| Ф15 |

13.8 |

72549 |

>60 |

>10000 |

| Ф17 |

20.1 |

49838 |

>10000 |

| Ф20 |

32.7 |

30607 |

>10000 |

| Ф25 |

64 |

15671 |

>10000 |

| Ф30 |

110 |

9069 |

>10000 |

| Ф40 |

261 |

3826 |

>10000 |

| Ф50 |

510 |

1959 |

>10000 |

| Ф60 |

882 |

1134 |

>10000 |

| Ф70 |

1401 |

714 |

>10000 |

| Ф80 |

2091 |

478 |

>58

|

>10000 |

| Ф90 |

2977 |

336 |

>10000 |

| Ф100 |

4084 |

245 |

>8000 |

| Ф120 |

7057 |

142 |

>8000 |

| Ф130 |

8740 |

115 |

>8000 |

Four Major Advantages Stronger and More Wearable

(1)Customized Raw Materials

(2)Advanced Full-automatic Production Line

(3)Unique Heat Treatment Technology

(4)Rigorous Quality Control System

Product Image

Img 1

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,