| Model: | - |

|---|---|

| Brand: | OUJIA |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Wire Mesh |

| Label: | gabion mesh , woven mesh , filter cap |

| Price: |

US $100

/ pc

|

| Min. Order: | 10 pc |

| Last Online:13 Dec, 2017 |

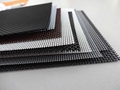

Details of steel grating

1. Name: It is made of low-carbon flat steel,in accordance with a certain spacing and then crossbar staggered, and welded into the middle of one kind of steel mesh-like product with a square lattice.That can be used to the drain cover, steel platform boards, steel ladder treads, etc.The crossbar generally is used the twisted square steel composition。

2. Material: Low carbon flat steel, stainless steel

3. Surface treatment: hot dip galvanized, electo galvanized, spray painting , prevent slippery oil

4. Dassification:

1) According to the welding type,it can be divided into:splicing steel,pressure welding steel grating,Shuttle steel grating and wear welding steel grid plate

2) According to the surface shape of bearing bar,it can be divided into:flat type,S type and I type

3) According to the use,it can be divided into:trench cover (drain cover), steel ladder (stair treads), platform steel grating, composite steel grating, steel board ceiling grid and so on.

4) According to the material,it can be divided into:stainless steel grating,carbon steel grating

5) According to the surface treatment,it can be divided into:hot-dipped

galvanized steel grating,eleco galvanized steel grating,spraying steel grating,PVC coated steel grating

5. Specification:

|

Steel grating production standard |

|||

| Bar grating standard | Steel standard | Hot-dipped galvanized standard | |

| China | YB/T 4001.1-2007 | GB700-88 | GB/T 13912-2002 |

| US | ANSI/NAAMM(MBG531) | ASTM(A36) | ASTM(123) |

| England | BS4592 | BS4360(43A) | BS729 |

| Australia | AS1657 | AS3679 | AS1650 |

| series | spacing of bearing bar | Spacing of cross bar |

Bearing bar standard(weight*thickness) |

|||||

| 20*3 | 25*3 | 32*3 | 40*3 | 20*5 | 25*5 | |||

| 1 | 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | ||

| 2 | 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | ||

| 3 | 60 | 50 | G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 | |

6. Steel grating series of three different uses:

Steel grating has a wide range of applications in all kinds of factories at home and abroad, such as power plants, chemical plants, oil refineries, steel plants, machinery factories, paper mills, cement plants, pharmaceutical, food processing plants.

For a variety of ship's gangway, channels, pumping stations, the engine room platform.

For a variety of bridges, such as the railway bridge side of the road, overpass approaches like plank walkway.

Used as platform for oil production plant, car wash, aerial tower .

Used as drainage covers, ditch cover for parking,municipal engineering, buildings and large venues fence, road fence, road .

1) Series 1 (spacing 30mm): steel grating is the most common type, use for the various industrial fields.Such series of grating bearing bars center distance by 30mm, in line with US standards, in the entire steel grating series , with the strongest impact on the surface resistance. It is widely used in power plants, refineries, sewage treatment plants, silos, chemical plants, highways, airports and container terminal platforms, walkways and drain cover, stair stepping and so on. Tooth(S Type) steel grating be used for wet, slippery places, especially for offshore oil platforms.

2) Series 2 (pitch 40mm) steel grating is the most economical and lightweight, in line with British standards for fixed platforms, walkways and stairs specifications.In the small span of occasions, this is the best product, even in the aisle transport equipment under that kind of load is no exception.But also can be used for storage shelves, pavilion panels, bridge, protective fence, sun screens and the like.

3) Series 3 (spacing 60mm) steel grating is designed specifically for the application for the mining industry and the development of varieties.It solves that the mineral splash on the plate.This series of steel grating having a nominal size of 50 * 60mm through empty to allow most of the splashed material wear off, thus ensuring a clean and safe plate surface.Such products are often designated for use in the broken system board , conveying line walkways and ball mill, processing plant and operation station.

7. Detail specification:

1) Dense steel grating

Dense steel grating: the spacing of bearing bar less than 25mm. In addition to its fully equipped with standard bonding steel grating in the form of beautiful, easy installation, etc.But also meet some special occasions that are strict requirements with the size of the through and leave out object.For example: a large crowd of civil applications, the steel grating can meet the requirements of Ms high heels walking; large crowd of industrial and mining enterprises, the requirements do not allow larger objects (such as diameter less than 20mm steel ball) down to meet the security requirements

2) Composite steel grating

Composite steel grid plate is a product with a certain combination of capabilities across the steel grating and checkered plate sealing surface or stencil made.It can be used with any type of steel grating patterns and different thickness of steel plate or a variety of steel composition. In addition it has a total structure of steel grating also has the characteristics that can prevent small pieces falling, use in the granary, restaurants, warehouses.

3) Flat steel grating

Use the flat steel grating different specifications of flat steel edging, or angle, channel, square tube, etc. Hemming, in the surrounding steel grating by welding kick plate (wall plate), checker plate shield, install connection parts and other accessories. Extremely wide range of applications, a variety of platforms in general factory, workshop, mining, ports can be selected.Beautiful style, easy installation, is a new construction product is provided replacement.

4) Pressure welding steel grating

Pressure welding steel grating is made of a composite steel and bars with certain distances, the use of 200 tons of hydraulic resistance welding automation equipment welded into the original plate, after cutting, opening, edging and other processes processed into customer requirements.

5) Splicing steel grating

Have the features of high strength, corrosion, maintenance-free with a bonding steel grille,and unique combination of homogeneous precision,lightweight structures beautiful,natural and harmonious,elegant style features.Solid solder joint product, pitch uniform, flat surface, and beautifully designed.

According to production can be divided into full-type plug, plug type and semi-slant type three.

6) S type steel grating

Features: Strong anti-slip ability, especially for wet, slippery places, offshore oil platforms, etc.

7) Trench grate

Trench cover is a grid of steel plate welded sewer or drain cover, it has a simple construction installation, light weight, carrying good, good impact resistance, rather bend do not break, displacement of large features.

8) Deformed steel grating

Structure: Spliced into circular, trapezoidal, semi-circular, fan-shaped and so on. Firmly welded mesh to have high bearing, structural lightweight, easy loading and other characteristics.Appearance and durability. Special specifications customers can request custom processing.

9) Step steel grating