| Model: | WYLM-1300 |

|---|---|

| Brand: | WAYARN |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | extrusion laminating , laminating machine , coating machine |

| Price: |

US $1000

/ Sets

|

| Min. Order: | 1 Sets |

| Last Online:16 May, 2018 |

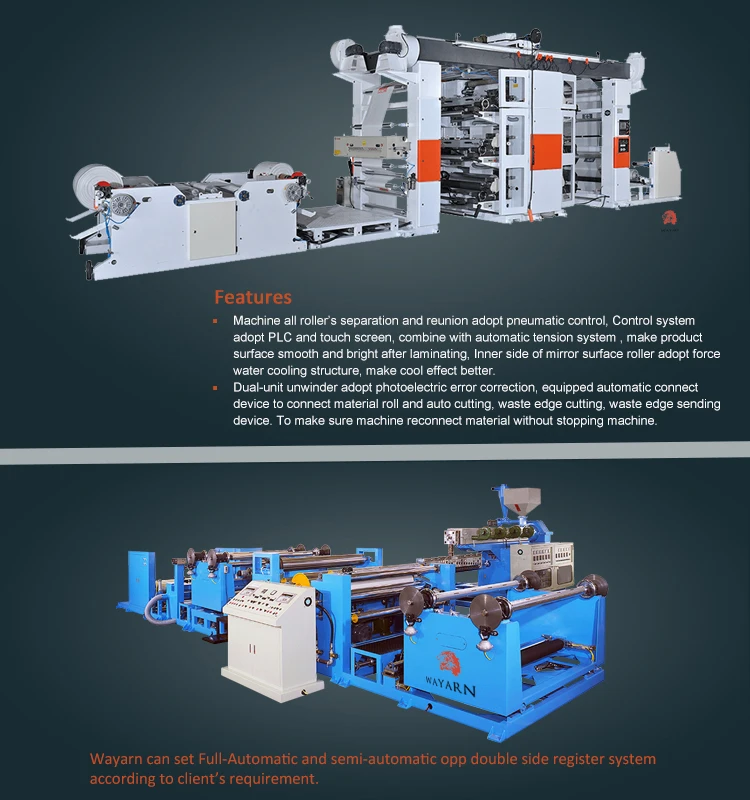

Dual Host Dual Die Head Laminating Extrusion Machine

Hot sales LDPE PP EVA EAA extrusion coating machine extrusion laminating machine

Laminating Machine

Descripations of Extrusion Laminating Machine

♦Wayarn extrusion laminating machine coats film such as HDPE on surface of paper (as raw material for making paper disposable cup, or shopping paper bags), non-woven fabric (for making non-woven bag) Extruding flow membrane & cartoons (brown packing paper, paper for cup, good quality paper) clothing metal foil, milkTetra Pak bag, plastic bags as well as other synthetical material.

♦Wayarn extrusion laminating machine is adopts computer orientation, photocell tracking, operation by man-machine interface touch. It's adopts high waveband ultrasonic heat. It have functions like hemin bag orifice, therading, punching, ultrasonic heat sealing cold cutting etc. It's a advanced machine for all kinds of non-woven fabrics handle shopping bag, shoes bag, ha k as 15-50g. Our company can make special design according to customers' different bag need.

Machine Advantages

Advantages of Extrusion Laminating Machine

Wayarn extrusion laminating machine takes the material like paper, plastic film, spinning and non-woven cloth or Al foil as raw materials. The materials (inter-layer compounding) through casting in one processing. They are widely applicable for packingbags for feed, adhesive tape cloth, snack boxes and non-woven cloth) Its PLC if of man-machine interface that can centrally control. It's intergrally designed with machine, electricity and gas system. It has a mould die with high precision, high-speed high-effective mixing screw rods. The user can last exchange the filter screen . It has the second unwinding frame which can rotate within 360-degree. It can be additionally assembled with a single extruder, double extruders, which can extrude in multi layers at the same time.

♦The machine is equipped with auto feeding device, save labor and energy.

♦The cooling roller has gone througth glzing treatment, the surface is smooth, the diameter is big.

♦The unbending roller can make the base material more smooth, and aovid wrinkle

♦The machine can make double side lamination,and compound with five different materials.

♦The film on the compound material is well distributed, it has good adhesion ability and tensile strength.

♦Range of Application:Packing plastic paper,paper cup,paper bowl,release paper,label,stationery paper etc.

Functions &Parameter

Functions & Parameters of Wayarn extrusion laminating machine

♦Applying material : roll base paper, PET,BOPP,non-woven,PE,PP woven fabric and so on;

♦Coating material: PE,PP;

♦Coating width: 1100~1800mm;

♦Thickness of coating: 0.015~0.05mm

♦Symmetrical degree of coating: +5%;

♦Peel off strength: 3-5N/30mm(according to the extruding material);

♦Machine design speed: 220m/min;

Company Information

Contact Us

| Payment Terms: | TT/LC/DP/DA |

|---|---|