| Model: | SJZ80/156 |

|---|---|

| Brand: | Acemien |

| Origin: | Made In China |

| Category: | Construction & Decoration / Brick & Tile / Bricks Tiles |

| Label: | roof sheet machine , plastic roof machine , extruder machine |

| Price: |

US $100000

/ set

|

| Min. Order: | 1 set |

| Last Online:13 Nov, 2018 |

PVC+ASA antique glazed roof tile/roofing sheet extrusion machinery

Product Description

Model SJZ65/132 SJZ80/156

Product width (mm) 840-1130 1130-1450

Product Thickness(mm) 0.8-3 0.8-3

Product Wave form circular/trapezoidal wave circular/trapezoidal wave

Max. extrusion capacity(kg/h) 250 400

Extruder power(kw) 37 55

Product Feature

PVC corrugated roof tile has a character in noise reduction, heat insulation and acid and alkali corrosion resistance, colorful; it can instead of color steel plate. Corrosion resistance, aging resistance, long service life (> 25 years)

Product Specification / Models

PVC corrugated roof tile extrusion line consists of:

1) Extruder: adopts conical twin-screw, it is designed specially to for PVC material.

2) Screw barrel: guarantee excellent plasticizing effect for all kinds of formula. The screw is equipped with internal temp. Controlling device as well as good cooling system for barrel, this assures precise temp.control for material during processing. Guarantee good quality of product with vacuum degassing device,which can get rid of moisture and waste gas from material.

3) Gear box: high torque transmission system, the gear and shaft are made of super alloy steel, which can meet the requirements of high torque, low noise, stable running.

4) Barrel cooling: it has good cooling effect with high quality ceramic heater.

5) Extruding die: the advanced design of multi-channel assure the plastic flow coming out from the wide die lip, the clearance of die lip can be freely adjustable.

6) Heating unit: it applies performing treatment to meet forming requirement before coming to second processing.

7) Forming unit: its suitable design ensures quick forming, exact size of sheet...

8) Haul-off unit: it is of simple two-roller take-up design, clearance can be freely adjusted, and it adopts frequency conversion speed control, which ensures various extrusion speed and stable running.

9) Cutting unit: feasible cutting style, the super alloy steel blade ensures quick and smooth cutting.

10) Control system: variety of control system available for different customer's requirement. (Such as PLC control)

Application / Models

High-grade plants, steel factories, warehouses, farm market, market access, sheds and other high-end roofing materials. Especially in corrosive chemical plants, smelters, ceramic plants, soy sauce factory, chemical plants, printing and dyeing plant, organic solvent factory, acid, alkali and other corrosive plant

Other Information

1.PP material wave tiles are mainly used in packaging, decoration, insulation, backing plate. They are green god. They are popular in Europe, the United States and Japan.

2.PVC material wave tiles are mainly used in packaging, decoration, insulation, lighting and so on. They are green god. They are acid-proof, durable and alkali-resisting.

3.PC wave tiles are not acid-proof, durable, alkali-resisting. But they are high temperature resistance, good lighting effect.

Main technical data:

Extruder Model SJZ80/156 +SJ50/30

Product width(mm) 880/1050

Product thickness(mm) 2-3

Wave distance(mm) 160

Wave length(mm) 220

Wave width(mm) 30

Motor power(kw) 55

Maximum output (kg/h) 300-400

Machine list:

No. Name Qty

1 Screw loader 1set

2 SJZ80/156 conical twin screw extruder 1set

3 Vacuum pellet loader 1set

4 Drying hopper 1set

5 SJ50/30 single screw extruder 1set

6 Extrusion mould and distributor 1set

7 Embossing roller 1set

8 Water temperature controller 1set

9 Forming machine(with side cutter) 1set

10 Cutter 1set

11 Stacker 1set

Auxiliary machines:

No. Name Qty

12 Ridge tile forming machines and moulds(main ridge tile diagonal ridge tile, three-way ridge tile and end ridge tile), ridge tile oven 4sets

13 Mixer unit 1set

14 Screw loader 1set

15 Crusher 1set

16 Pulverizer 1set

Product Description

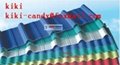

1)PVC+ASA two layer co-extrusion Roofing tile .ASA layer for anti-UV for longer life using.

2)product standard width 880mm or 1040mm,thickness 2-3mm adjustable, Other size can be customized

3)The Turnkey machine contain main tile extrusing machine,Ridge tile(4 type) forming machine,mixer,crusher,pulverizer... The offer is a Turnkey project.

4)The capacity :for 2mm thickness ,2000m2(24 hours), for 3mm thickness,1500m2(24 hours)

5)product surface color have much type for your choice,so the product have beautiful outlook than normal tile(ceramic tile,steel tile,concrete tile).

Product Feature

heat insulation, sound insulation, water resistance, chemical and alkali resistance, corrosion proof, fire retardant, eco friendly, easy to install and move, light weight as well as cost effective in installation (as less steel and less overlap), as per the efficiency and benefits it provides.

Product Specification / Models

SJZ80-BF880

Application / Models

product are used for Flat-to-sloping projects , villas, mobile homes, garden pavilion roof and other areas.

Other Information

We specialized in plastic Roof tile making machine.

Expect for your inquiry.

Our Services

- pre-sales services: we will take customers to visit our factory and check the machines quality from airport/bus station/train stations

- we will re-designed the machines according to customer's different raw material formulations: driving motors power, electric power model, wall thickness of barrel, control method

- after sales services: we will offer electric diagram, installation diagram, usage manual

- we will offer the customers online introduction to solve the machines problems/send engineers for customers machines installation, running test, workers training, machines repairmen services.

- we will offer customers spare parts at cost prices all life long of the machines