Automatic Dies Vertical Grinding Machine for Feeding and Biomass LM1500A

Product Description

Key Specifications/Special Features:

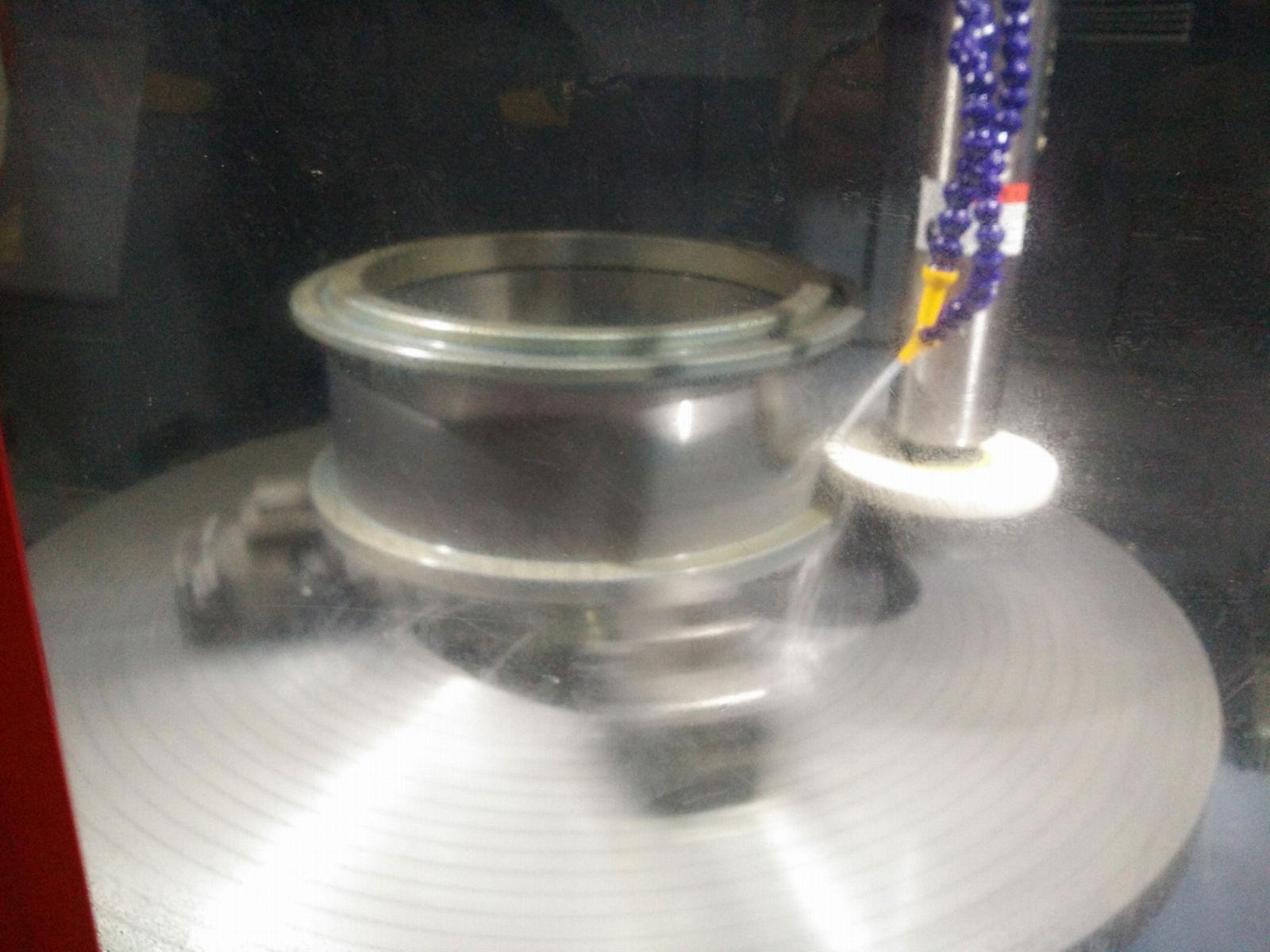

This machine is used on feeding pellet mill product and other biomass pellet mills such as wooden pellet and straw pellet, it is suitable for holes machining operations such as grinding and milling, it is not only used on new ring die but also appropriate for old ring die

Equipment features:

1. Vertical type principal axis, super big workbench which may supports all kinds of ring die size

2. High-rigidity principal axis, big workbench and vertical type of clamping ring die which may reduce the chucking power impact of ring die transfiguration

3. Machine is suitable for various types of grinding wheel and it has the function of grinding wheel auto-repair so that guarantee ring dies grinding high-efficiency

4. Mltor adapted a famous brand of balls crew and linear guide way and combining with reliable automatic lubrication design, Mltor machine is durability and stability

5. User-friendly interface on CNC control system is easy to operate and Mltor CNC control system is the customized support that the user may choose programming or fool-style operation

6. System comes with a diagnostic interface, it is easy to find out the reason of the control failure so easy to repair

7. There is a cycle of water-cooled design, overflow filtration, to avoid overheating and dust of the ring die

8. Mltor uses frequency control for grinding wheel and workpiece speed, stepless speed variation to satisfy the requirements of best grinding

Services for item:

- Machine warranty period 12-month once the customer receives the machine, after 12-month, we may answer the customer's question on line or by E-mail within 24-hour

- Mltor will prepare one more set of quick-wear components with the machine for the customer

- Mltor will not provide or change any part or component for free if the customer damages them abnormally, the customer needs to purchase them separately

- Mltor will afford the customer's technician local transportation, accommodation and catering cost when the customer's technician comes to Mltor factory to have a train or inspects the machine before the machine delivery and the customer will afford their technician travelling cost

- In the warranty period, if the customer requests Mltor engineer to support in foreign country, Mltor will support to check equipment and train the customer technician for free but the customer needs to afford Mltor's engineer travelling expenses, local transportation, accommodation and catering cost

| MLT-LM1000 main specifications |

| Maximum ring die external diameter |

1000mm |

| Minimum ring die inner diameter |

300mm |

| Maximum ring die width |

430mm |

| Maximum ring die weight |

1000kg |

| Grinding supports as |

Inner, outer surface, end side and conical surface |

| Grinding wheel repair |

Supports self-motion and manual-motion |

| Grinding wheel choice |

Brown and plate shape grinding wheel |

| Cooling system |

Circulating water-cooling |

| Grinding head axis parameter |

| Motor power |

4kW |

| Grinding head rotating speed |

1000-4000 (frequency device for Mitsubishi) |

| Work piece axis parameter |

| Motor power |

4kW |

| Rotating speed of workbench |

0-60rpm/min (frequency device for Mitsubishi) |

| Max bearing weight of workbench |

1000kg |

| Workbench surface size |

1000mm |

| NC control and electric system |

| NC control system |

MLT-208 |

| Control axis |

X axis + Z axis |

| Servo motor |

Alternative current servo motor drive |

| Electric cabinet air-condition |

DLW5, compressor refrigeration |

| Voltage |

AC 380V 3P |

| Frequency |

60Hz (adjustable) |

| Rated power |

11.1KW |

| Machine size |

1990mm x 2275mm x 2510mm |

| Machine weight |

5200kg |

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,