| Model: | SWP-400 |

|---|---|

| Brand: | S |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | crusher , plastic crusher , shredder |

| Price: |

US $3500

/ pc

|

| Min. Order: | 1 pc |

| Last Online:23 May, 2018 |

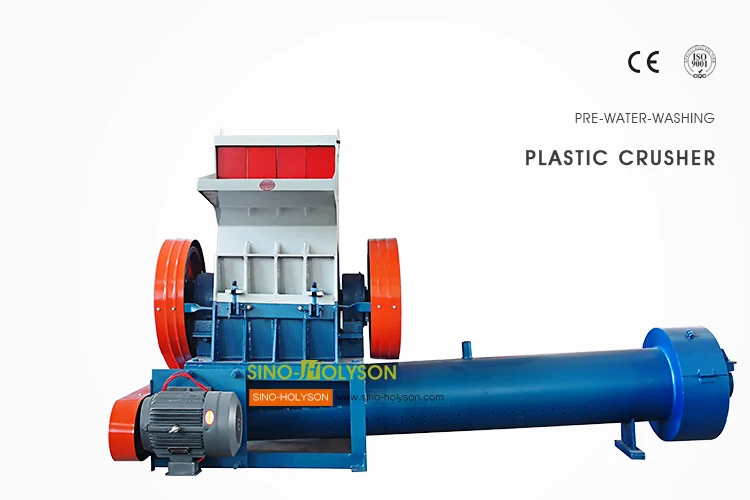

SWP-360 PLASTIC CRUSHER MACHINE

General Introduction:

This Plastic Crusher is suitable for crushing various kinds of pipe material, profile, polypropylene, nylon, engineering plastics, plastic wood and polychlorine foam soft material waste, subproducts or injection nozzle etc.

It is made of high quality steel plate, the fuselage is welded into the cavity by the double layer and the bearing seat is prepared by the body.

It can collect domestic and foreign advanced technology, adapt to various medium, small pieces of the crushing of the material.

Time-saving, large crushing, high crushing efficiency, good safety and environmental protection, and power saving.

Outstanding Advantages:

Adopt imported special tool steel refining tool, and the clearance can be adjusted.

With high strength steel screw fastening blade and blade, the bearing capacity is strong.

Low speed and sound insulation are adopted to minimize noise.

The motor has been equipped with protection and power supply chain protection device, which protects the motor and operator.

The feeding hopper adopts optimized design, special anti-rust treatment, and avoid the leakage and pollution of materials during crushing process.

Separated design, hopper, main body, sieve screen base is easy to unpick.

The perfect design of the discharging device makes it extremely convenient for operators to clean up.

Stepped blade design, crushing force strong.

DETAILED IMAGES

SINO-HOLYSON, a professional plastic extruder manufacturer, delivers MADE-TO-ORDER service,

please send your sample pictures by mail. Our PROPOSALS will be feedback soon by engineer team.

WITH CE & ISO9001 CERTIFICATION, OUR QUALITY MACHINE WILL SATISFY YOU VERY MUCH.

|

Pre-Sales Service |

After-Sales Service |

|

* Inquiry and consulting support. * Sample testing support. * View our Factory. |

* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas |

Before delivery, our working staff will carefully pack the whole set machine to make sure the products arriving to customer's workshop safely.

LCL (Less than Container Load) > WOOD CASE Packing + Cline Film Wrapped + Steel Tube Tray Fixed + Oil Against Rust Process

FCL (Full Container Load) > Steel Tube and Wire Fixed + Cling Film Wrapped + Oil Against Rust Process

| Payment Terms: | TT |

|---|---|