| Model: | DY10 |

|---|---|

| Brand: | DY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | plasticpyrolysis , pyrolysis plant , plastic recycling |

| Price: |

US $50000

/ set

|

| Min. Order: | 1 set |

| Last Online:12 Nov, 2019 |

The DoingGroup's waste plastic to fuel pyrolysis plant is a high-temperature pyrolysis chemical reaction performed in an oxygen-free environment. This reaction can reduce the bulk of macromolecular compounds, waste plastics or other organic solids into small pieces. Of course, in addition to waste plastics, you can use this pyrolysis plant to treat other organic solids, such as waste tires, waste rubber, and other organic solid waste.

The DoingGroup has always been committed to the research and development of pyrolysis plant and has made its contribution to the industry second to none. With the maturity of the domestic market, DoingGroup has turned its sights around the world and established an office in Thailand. At the same time, we have the waste plastic to fuel pyrolysis plant known and sought after by people in various countries around the world.

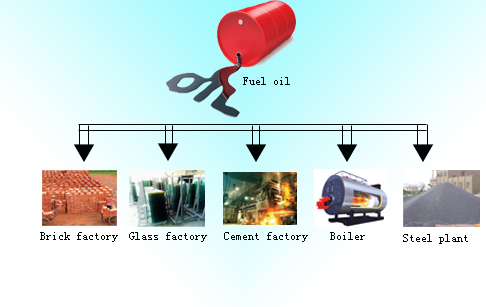

The DoingGroup's waste plastic to fuel pyrolysis plant is so popular because of its high oil output rate. Our equipment has different capacities. Taking 10 tons of equipment as an example, 4.5 tons of fuel can be obtained in one day of operation. According to the conservative calculation of the value of fuel in the market, a day's worth of 1,800 dollars will be obtained for the fuel produced by the equipment. Of course, this benefit does not include carbon black and the income of steel wire.

So why did the DoingGroup's waste plastic to fuel pyrolysis plant are so high?

First of all, DoingGroup's waste plastic to fuel pyrolysis plant is designed with a vacuum device, which can provide negative pressure and drain oil and gas. This device ensures that even if the oil and gas are not fully condensed in the condensing system, they will pass through the pressure and be filtered again in the condensing system until the oil and gas are fully filtered.

Second, use the most advanced and most effective condenser in the industry. This type of condenser uses column tube condensation, also known as a three-stage cooling system, which ensures that the cracked oil and gas is fully cooled and the oil yield is high.

Finally, the DoingGroup's waste plastic to fuel pyrolysis plant has oil-water separators. It not only can purify oil and gas, and separates water from oil and gas, but also can prevent the backflow of oil and gas and increase the oil yield.

Doinggroup has won good reputation with its advanced production technology, professional installation and after-sales service.The main products: waste tire pyrolysis plant, continuous waste tire pyrolysis plant , waste oil to diesel Refining Machine with relavent equipements, like tire cutter, carbon black briquette machine and carbon black grinding mill etc;scrap cable wire recycling machine. PCB (Printed Circuit Board ) recycling machine. Aluminum and plastic composition recycling machine. Home electric applaince recycling machine, etc.

Welcome your visit!

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:market@doinggroup.com

http://www.continuouspyrolysisplant.com

VIew more: pyrolysis plant continuous tyre pyrolysis plant

waste tire to fuel oil pyrolysis plant

continuous waste plastic pyrolysis plant

| Payment Terms: | TT/LC/DP/DA |

|---|---|