Product Description

HL Ultrasonic level meter for continuous non-contact level measurement in liquids and solids. It consists of probe and host, both of which are plastic leak-proof structure. The HL series can be widely applied to the metallurgical, chemical, electricity and oil industries.

Principle of ultrasonic sensor for level measurement

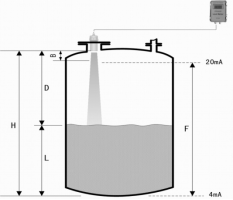

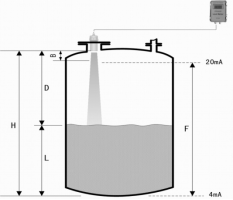

The sensor of the meter pulses in the direction of the product surface. There, they are reflected back and received by the sensor. The meter measures the time t between pulse transmission and reception. The meter uses the time t (and the velocity of sound c) to calculate the distance D between the sensor membrane and the product surface: d = c •t/2. As the device knows the installation height H from a user entry, it can calculate the level as follows: L = H – D .

B: blacking distance

D: distance value

L: level value

H: installation height

F: full span value

L=H-D

An integrated temperature sensor compensates for changes in the velocity of sound caused by temperature changes. Calibration Enter the empty distance H and the span F to calibrate the device.

Blanking distance: Span F may not extend into the blanking distance B. Level echo from the blanking distance cannot be evaluated due to the transient characteristics of the sensor.

Product Image

Img 1

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,