Pet Laser Film for Laminated Tinplate Sheet Coil

Product Description

Production process

Adopt plastic film(PET,PP,PE) combined with metal plate through hot melting or bonding, which has solved the corrosivity of metal plate and metal container, both has the decorating, barrier of plastic film and the malleability, figurability of metal sheet.

Metal plate: tinplate , chromium plated iron, galvanized sheet, baseplate (SPCC, SPHC, Q195)

Plastic film:PET, PP, PE ,Resin-film etc.

Film color:White film, transparent film, aureate film, color film, laser film and so on

Production management

Production workers will participate in unified training before passing the exam.

A preliminary examination before the product process, the process of two re-examination, the finished product sample after the three tests as to guarantee the product to be of quality.

Quality control

A combination of machine instrument testing and manual re-inspection are adopted. Quality inspectors have more than ten years of experience in quality experience. The company uses machine data monitoring checks, as well as multiple quality inspection staff to re-check and ensure that the test results are accurate and effective.

Sales service

How to solve some quality problems?

Due to the production of raw materials and transportation problems may occur.

Production workshop technology department and inspection department to be addressed accordingly and will find a solution meeting customer requirements.

The shipping company and the manufacturer communicate with the insurance company to meet all customers expectations.

| Standard for Temper: |

|

|

|

|

|

| |

|

|

|

|

|

| code |

Chinese Stardard |

Japaness Standard |

American Standard |

European Standard |

International Standard |

| |

GB/T 2520-2000 |

JIS G3303-2002 |

ASTM A623M-2002 |

DIN EN 10203-1991 |

ISO 11949-1995 |

| T-2 |

TH52+SE |

T-2 |

T-2(53) |

T52 |

TH52+SE |

| T-2.5 |

TH55+SE |

T-2.5 |

|

|

TH55+SE |

| T-3 |

TH57+SE |

T-3 |

T-3(T57) |

T57 |

TH57+SE |

| T-3.5 |

|

|

|

|

|

| T-4 |

TH61+SE |

T-4 |

T-4(T61) |

T61 |

TH61+SE |

| |

|

|

|

|

|

| Coating weight: |

|

|

|

|

| Classification |

Designation of tin coating weight |

Nominal tin coating weight(g/m2) |

Min average tin coating weight(g/m2) |

Remark |

| Equal tin coating(E) |

1.1/1.1 |

1.1/1.1 |

1.8 |

All specification |

| 2.2/2.2 |

2.2/2.2 |

4 |

All specification |

| 2.8/2.8 |

2.8/2.8 |

5 |

All specification |

| 5.6/5.6 |

5.6/5.6 |

10.5 |

All specification |

| Differential tin coating(D or A) |

2.2/1.1 |

2.2/1.1 |

2.0/0.9 |

All specification |

| 2.8/1.1 |

2.8/1.1 |

2.25/0.9 |

All specification |

| 5.6/1.1 |

5.6/1.1 |

5.05/0.9 |

All specification |

| 2.8/2.2 |

2.8/2.2 |

2.25/2.0 |

All specification |

| 5.6/2.2 |

5.6/2.2 |

5.05/2.0 |

All specification |

| 5.6/2.8 |

5.6/2.8 |

5.05/2.25 |

All specification |

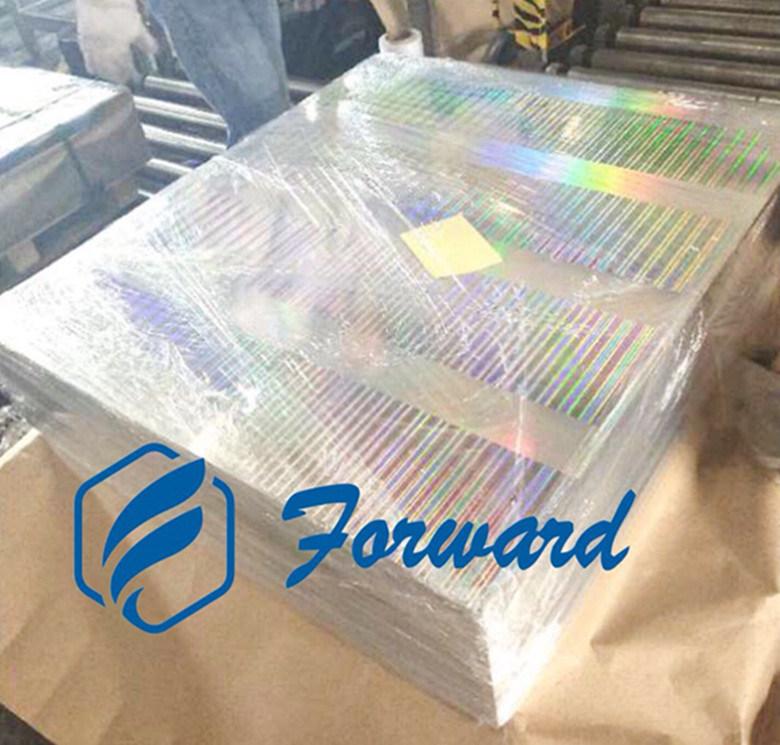

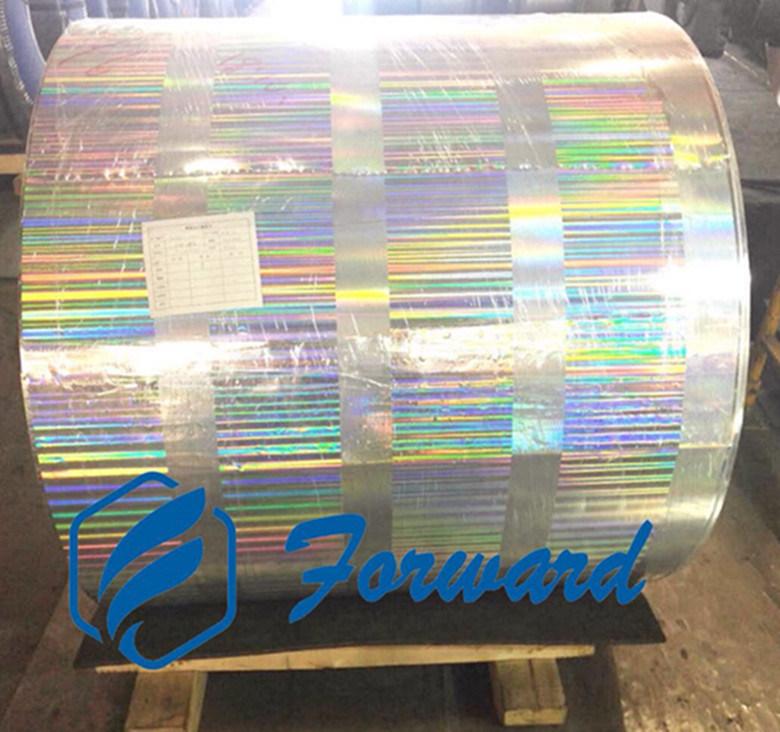

Product Image

Img 1

Img 2

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,