| Model: | - |

|---|---|

| Brand: | utand |

| Origin: | Made In China |

| Category: | Construction & Decoration / Slate, Marble, Granite & Stone / Countertop & Vanity Top |

| Label: | engineered quartz st , artificial quartz st |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:30 Oct, 2019 |

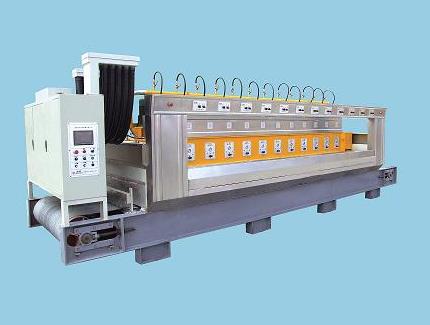

engineered quartz stone machinery

Utand Advantages:

Utand engineered quartz stone machinery is the best choice of the engineering quartz stone manufacturers, provide a one-stop solution to engineering quartz stone product line, more than 21% of construction costs are saved!

machine Advantages:

Engineered quartz stone machinery CNC automation degree is very high, improve production efficiency, reduce the failure rate, 9 patents to ensure our product of engineered quartz equipment production quality better!

cases Advantages:

Utand engineered quartz stone machinery has been used in more than 260 engineering quartz manufactory, the profit for our customers and at the same time for us to win the honor, utand stone machinery are China's first brand for engineered stone equipment, welcome global customers to visit our factory, we field test for you or take you to see our equipment working!

engineered quartz stone machinery product line

utand engineered quartz stone machinery Has a group of professional technical team, sales team and service team, the company has always been to keep pace, and introduce the United States, Japan, Germany, Australia and other countries of advanced technology and experience, strengthening independent innovation, both in production capacity and sales is always in the domestic leading position, to become worthy of leading enterprises in China.

Engineered quartz stone machinery product line includes mixing machinery, pressing machine, curing equipment, cutting machine, calibration polishing equipment system:

1)mixing machinery for engineered quartz stone

In the Engineered quartz stone machinery product line, the single raw material is used in order to reduce the color difference. When stirred, use a planetary speed mixer to ensure that the ingredients are fully mixed.

mixing machinery for engineered quartz stone

Advantages:

engineered stone mixer machine adopt opening design, very easy to clean it. the mixer adopts planetary rotation way ,can prevent the emergence of lump.

Power:

56 (kw)

Applied material:

engineered quartz stone production line mix solid material and liquid material together!

2)making machine for engineered quartz stone

Engineering quartz plate under vacuum and high pressure and under the action of strong vibration molding,engineering quartz slab produced by high density, bibulous rate is low. making machine for engineered quartz stone pressure time by different formula, the thickness of the plate is different, generally for 2 ~ 4 min, after engineering quartz slab pressure, uncovering paper, shall ensure that each part is consistent with the paper/film bonding degree, cannot appear local bulge, when a finger touch, the entire board face must be consistent softness.

engineered quartz stone machine

Advantages:

engineered quartz stone machine simple and efficient, cost reduced by 35%,product Mohs hardness is7!

Max processing W*L:

Width :760~1650(mm) * Length:2440~3100(mm)

Applied material:

Artificial quartz stone production line and engineered quartz stone machinery production line!

3)cutting machinery for engineered stone slabs

In order to get the right product specifications, use the engineering quartz plate cutting machine to make the cut according to the size requirement, or to make the edge flat, and ensure that the plate size is fixed and uniform.

Advantages:

quartz cutting machine used in marble slab, granite slab, quartz plate of two-way edges cut or Vertical horizontal cutting machine.

External size:

4200×1500×1760 (mm)

Applied material:

artificial quartz stone slab and marble slab, granite slab!

4)calibration and polishing for engineered quartz stone machinery product line

the smaller the particle size is, the less the glossiness, after polishing glossiness generally at about 40 °. Particles, the greater the glass plate, especially contains large particles had higher gloss, after polishing glossiness general around 60 °.

engineered quartz Polishing machine the choice: generally choose surface in contact with the template as a polished surface, because this side of the flatness is better, smoothness, the cloth in the process of this side less sundries, curing process, the density is high. So it's ideal to use this side as a polished surface.

The choice of engineered quartz grinding block: choose quality granite stone grinding block and reasonable number collocation.

Polishing speed engineered quartz stone machine : the speed of polishing varies depending on the ingredients and the color of the plate. For small particles and pure color boards, the speed of the middle line should be slowed down. And the plate of big grain and glass grain and light color board, linear speed can be relatively quick.

Advantages:

stone calibration machine is designed for calibrate thickness before polishing artificial quartz stone slab. digital display and automatic controlled by electrical motor, to ensure accurate of the slab thickness!

Working width * thickness:

600~2100(mm)* 8~40(mm)

Applied material:

engineered quartz stone production line and artificial marble production line!

Advantages:

automatic Stone Polishing Machine is the most advanced product of stone industry upgraded,Suitable for nonmetal sheet grinding and polishing, high brightness, low operating cost!

Capacity:

150-300 square meter per 8hours

Applied material:

engineered quartz stone, artificial marble slab and more grinding stone slabs!

| Payment Terms: | TT/LC |

|---|---|

| Embed HTML Code: | This article comes from https://www.utand.com/engineered-quartz-stone-machinery.htm |