| Model: | YS-50 |

|---|---|

| Brand: | YUESHENG |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | 50L Home Brewing , beer brewery , beer equipment |

| Price: |

US $5000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:15 Jan, 2019 |

Hot Sale 50L Home Brewing Equipment For Beer

50L Beer Equipment Specifications Sample:

|

Item |

Model |

Technical Specifications |

|

Malt Mill |

200kg/h |

two roller mill, carbon steel shell, alloy rollers complete with motor, belt and pulley, motor power 2kw |

|

Mash Tun |

50L |

1.effective capacity 50L, total capacity 75L, 2.top dished head,material SUS304,thickness2.0mm, 3.inner wall: material 304 stainless steel;Shell thickness: 2.0 mm 4.Out wall: material 201 stainless steel; Out thickness: 1.5 mm wire drawing board 5.Insulation layer thickness is 80 mm;Rock wool insulation 6.Heating method: electric heating; 7.Temperature measurement way: digital display table shows 8.Welding method: argon gas protection welding, slinging band, classical style

|

|

Lauter Tun |

50L |

1.effective capacity 50L, total capacity 75L, 2.top dished head,material SUS304,thickness2.0mm, 3.inner wall: material 304 stainless steel;Shell thickness: 2.0 mm 4.Out wall: material 201 stainless steel; Out thickness: 1.5 mm wire drawing board 5.Insulation layer thickness is 80 mm;Rock wool insulation 6.Filter sieve plate: spacing of 1.0 mm; 7.Voltage: 220 v50hz 8.Leg: three leg |

|

Fermentation Tank |

50L |

1.Single tank control: spiral cooling jacket, the top clamp manhole;Hop dry mouth.

Water jacket thickness: 2.0 mm

Outsourcing: the thickness of 1.5 mm wire drawing board

thickness: 2.0 mm precision polishing

10.Ellipsoidal head, taper 60 Thickness: 2.0 mm |

|

Yeast Adding Tank |

2L |

effective capacity 2L, inside polished outside sand blast, associated valves and fittings |

|

Glycol Tank |

100L |

1.Dimension: 600 * 600;

Outsourcing: the thickness of 1.5 mm wire drawing board

thickness: 2.0 mm precision polishing

to water tankof water cooling,

welding;Weld slinging band |

|

Glycol Chiller |

2P 5000w/h (2HP)) |

Refrigeration capacity 8200W (5HP), air cooling unit, CE approved, environment protecting Freon, designed for local power supply |

|

Sanitizer Tank |

10L |

effective capacity 50L, interior & exterior 2b finish, welding seams brushed, associated valves and fittings |

|

Caustic Tank |

10L |

effective capacity 50L, interior & exterior 2b finish, welding seams brushed, associated valves and fittings, electric heating elements |

|

Control Cabinet |

800×600×200 |

1.Cabinet put oneself in another's position with gb GGD cabinet put oneself in another's position;

|

|

Digital Controller |

C2015 |

separate control for each fermentation tank, temperature local display & control on controllers |

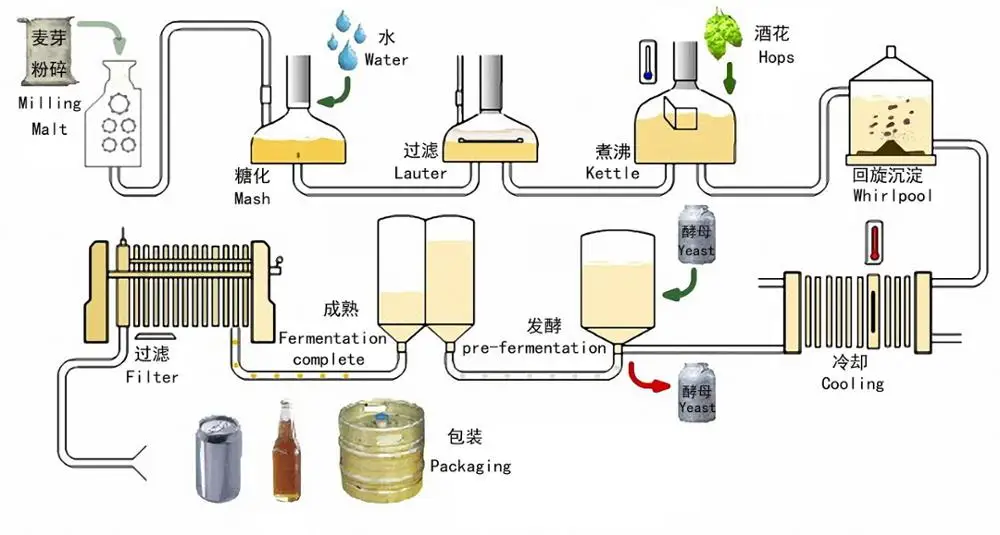

Home Brewing Equipment Process

Brewhouse System

1) inner wall SUS 304, 3mm;

surface stainless steel 304 or copper, 1.5mm

2) inside polishing 0.4-0.6 micron

3) dome top, side and top manway

4) insulation: polyurethane/rockwool 100mm;

with inside CIP ball, agitator, false bottom

5) Tangential inlet for whirlpool

Thermowell for temperature sensor and thermometer....

6) butterfly valves, clamps and gaskets

3 legs with adjustable bolts

Fermenter System

1) Glycol cooling jackets on both cylinder and cone

2) Inner wall stainless steel 304, 3mm;

surface SUS 304, 1.5mm

3) Dome top, conical bottom 60-72 degree, top manway

4) Insulation: polyurethane 100mm

5) Inside 360 degree CIP washing ball;

Inside polishing 0.4-0.6 micron

automatic pressure relief

working pressure: 0.15Mpa

testing pressure: 0.3Mpa

6) with thermowell and pressure sensor&gauge

Cooling System

1)Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

2)Efficiency chillers or refrigerators with fryon to supply cooling energy

3)Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

4)All pipes, fitting, insulation materials are included

Controlling System

1. Electrical controlling cabinet with temperature, on-off controlling for brewhouse

2. Electrical controlling cabinet with temperature, on-off controlling for cooling parts

3.Temperature controller, thermocouple, solenoid valves etc are included

4.PLC with touch screen panel for special request

Packaging & Shipping

Packaging:Wooden case package and steel frame package,besides,any other package ways suitable for overseas transportation

Shipping:Deliver from Qingdao within 30 days after the payment

Our Service

Pre-service

1) Our market team can serve you in 24 hours, so please feel free to contact at your convenient

2) Our dedicated engineers can supply 2D,3D drawing for you if you needed.

3) If you need to inspect our factory, we can book the hotel and make the invitation letter for you.

4) Our market team with our engineer with more than 10 years experiences together can satisfy you with any technology problem;

5) Customize machine can be offered(voltage,material,dimension,heating source and so on)

After-service

1) When shippment, we will supply a whole set of parts for backup.

2) If there is any parts damaged, we are surely can send the part to you in 24 hours.

3) Main machine is 3 years warranty, auxiliary machine is 12 months warranty,

4) Electrical components is 18 months warranty, life long service.

Why Choose Us?

1. Top cone is mirror polished

2. Shadowless manhole

3. Our skilled workers are with more than 10 years welding and related production experiences.

4. Our installation engineers are with more than ten years brewing experiences, which can train

or help you brewing customers-liked beers.

5. High quality milled falsed bottom installation method: special discharging hangle, easy to discharge and clean,;

6. Led cold light, bright , lower power consumption and lasting, other suppliers only use normal light ball;

7. Imported food grade rubber hose, long lift-span, safe and firm.

8. Large spent grain door, reliable sealing, with hopper, easy to make the spent grain out without ground pollution.

9. Mechanical pressure adjustable valves: plus and minus pressure protection, ensure the tank safty.

10. Complete quality control and management system: material IQC complete inspection, PQC production process inspection, OQC inspection after finishing production brewhouse installation 24 water leakage test and pressure test, fermenters cooling jacket pressure 24 hours test.

11. 3Years After-sales services for our goods.

12. Complete beer line to meet different capacities and all kinds of beer

13. Customize machine can be offered(voltage,material,dimension,heating source and so on)

CE Certification

Company Information

Shandong Yuesheng Beer Equipment Co., Ltd. is specialized in designing, manufacturing, installation, commissioning, technology and development services manufacturer.

The company's production, technology, management of experienced professionals are constituted to excellent performance, exquisite workmanship, appearance concise atmosphere, the design is compact, easy to learn for the purpose of manufacturing production equipment.

The company employed more than ten years of occupation by the beermaking team to provide customers with a full range of beer making technology consulting services, according to customer specific local market conditions, designed to meet our customers independent brewing process of the local market, allowing customers to produce beer to fit local actual consumer demand.

We will only do better than you imagine!

Yuesheng warmly welcome friends from all around to visit!

| Payment Terms: | TT/LC |

|---|---|