| Model: | SWC |

|---|---|

| Brand: | XINKAI |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Other Machine Hardware |

| Label: | Standard/Non-standar , 35CrMo 42CrMo flange , The casting and forg |

| Price: |

US $55

/ pc

|

| Min. Order: | 1 pc |

| Last Online:29 Nov, 2018 |

Product Description

SIMIS universal shaft couplings

Smoother/higher performance/easier maintenance

Flexible rotation

In the process of operation, the joint rotates flexibly and there is no lag.Spline pair expansion and contraction, high transmission efficiency.

Structure optimization

Drawing lessons from foreign design concepts, the capacity of continuously optimizing structural design to bear alternating torque was increased by 30%

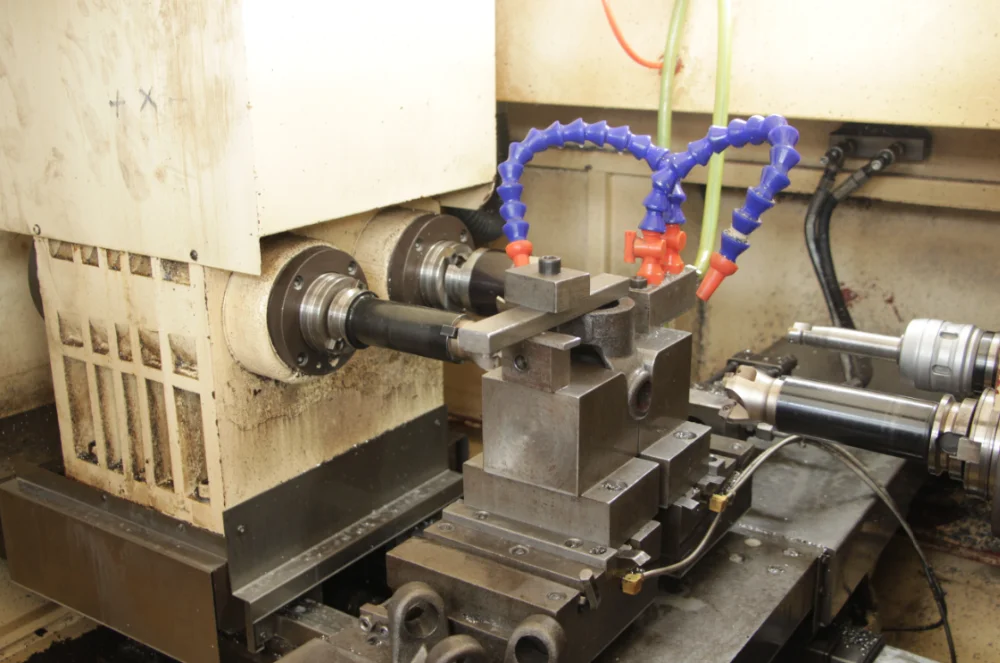

Excellent components

The introduction of advanced processing equipment, ensure the assembly precision of the workpiece, service life increased by 20%, save production costs.

Smooth operation

Special process, ensure the overall coaxiality of 0.5mm;More stable operation, critical speed up to 4000 RPM.

Surface anticorrosion

It can resist the damage of high heat, high temperature radiation, corrosive medium and strong light, and has stronger anti-aging ability on the surface.

Simple maintenance

Excellent double-side sealing design inside the bearing, the service life is more than 12,000 hours;Longer maintenance intervals

Custom specification for universal coupling

To undertake a variety of non-standard customized universal coupling - customized, production you need!

Applicable to machine industry: crusher, rolling equipment, petroleum machinery, rubber and plastic machinery, steel pipe equipment, paper machinery

Our advantages:

1. Flexible rotation: during operation, joints are flexible and there is no lag;Spline pair expansion and contraction, high transmission efficiency.

2. Smooth operation: special process to ensure the overall coaxiality of 0.5mm;More stable operation, critical speed up to 4000 RPM.

3. Structural optimization: learn from foreign design concepts and continuously improve the capacity of structural design to bear alternating torque by 30%.

4. Anti-corrosion on the surface: it can resist the damage of high heat, high temperature radiation, corrosive medium and strong light, and has stronger anti-aging ability on the surface.

5. Sophisticated components: introduce advanced processing equipment to ensure the assembly accuracy of the workpiece, increase the service life by 20% and save production costs.

6. Simple maintenance: excellent double-side sealing design inside the bearing, with a service life of more than 12,000 hours;Longer maintenance intervals

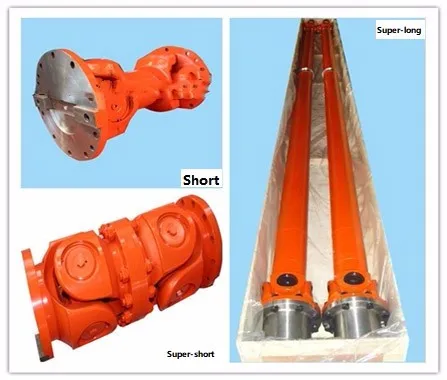

Detailed Images

Customized rules:

1, According to the length of customized universal axis

Our advantages: we developed the ultra-short SWCD universal shaft according to the needs of customers, which can shoulder the power transmission under the extremely limited installation space;At the same time, we also used a special process to produce 5-8 meters of universal shaft coaxiality can be controlled in 0.5mm.

2..By the spline type and stretch length customization

3.Customized according to flange connection

(1).Pure bolt hole joint flange

High strength bolts and self-locking nuts are used to connect the flanges at both ends, and the friction force of the flanges is used to transfer torque.This kind of flange design is suitable for universal shaft with low torque and high speed.Lightweight universal shaft flange design in the form of pure flange.

(2).The end key connects the flange

Under the joint action of the end-face key and high-strength bolt, the joint performance of the flanges at both ends is improved, and the transfer efficiency of the universal shaft torque is also increased.Generally used in equipment with medium impact load.Medium universal shaft flange design by the end of the key form.

(3).Insert joint flange

Use flange many concave and convex, and evenly distributed teeth with transmission torque, flange combination of stability is good, long service life.Suitable for heavy impact load, high frequency of positive and negative rotation of equipment occasions.

(4).End face tooth joint flange

Angle of tooth profile to achieve universal shaft flange with half coupling flange connection.Flange connection self - determination is good, easy to install.This flange is often used in heavy duty universal shaft design.

4.Built-in spring universal shaft customization

What are the advantages of this design process?

The two ends of the cardan shaft can be installed and run, but the problem comes. The active end connection of the cardan shaft is tight and not easy to loose, while the passive end connection is often loose and easy to disengage after running, so that the efficiency of cardan shaft torque transfer is reduced.Add the built-in spring universal axis so that the combined parts do not shrink back in the working state, keep the length of the fit unchanged, increase the stability of the transmission.

5.Customized universal shaft with protective sleeve

Advantage:

Add protective cover on telescopic mechanism, make the service life of spline can be longer.

Spline shaft with protective sleeve, so that the internal and external spline relative movement, the external environment of dust and water can not enter the internal spline, so that the service life of the spline pair is longer.Especially suitable for limited lubrication conditions and poor service environment.

6.Optional surface treatment

Usually in order to ensure the normal use of universal coupling, we will deal with its surface, so as to effectively avoid its surface rust, erosion and other bad phenomena, thus affecting its use.

(1) flame quenching: the surface of the coupling is quenched by means of rapid heating and cooling of oxygen.

(2) carburizing: carbon diffusion is distributed on the surface layer of the coupling, and the polishing temperature is 850, resulting in the shape.

(3) blackening: it is mainly divided into heating blackening and constant temperature blackening. Among them, the blackening by heating is better than the blackening by constant temperature. The cost of blackening by constant temperature is higher.The theorem is to use potion to turn the surface of pig iron into gray, shift gears, guard against rust, erosion.

(4) electroplating: the coupling as the cathode is placed in the electroplating tank and the metal film is deposited on the surface of the substrate in the form of electrolysis through direct current.

(5) induction quenching: high frequency induction current is used to quench the surface layer of the substrate after rapid heating and cooling. However, it should be noted that the quenching thickness should be 0.5~5mm, the operation time is relatively short, and the substrate shape is relatively small.

7.Successful cases: OEM customization of German wanxiang shaft

Our Company

The factory covers an area of 26,700 square meters, with 39 series of products and nearly 3,000 varieties. About 500 sets of plastic molds and aluminum die casting molds are manufactured every year, with an annual output of 500,000 cases and shells.The company's largest aluminum die-casting machine is 1250 tons, the largest injection molding machine is 6300 grams, the largest stamping machine is 100 tons, the largest processing center area is 1500*1200, various processing equipment such as CNC puncher, bending machine, drilling and milling integrated machine and laser cutting equipment 120, the production capacity is up to 15 million USD.The company has a perfect quality assurance system, processing quality to reach the international advanced level, welcome customers from all over the world to cooperate or OEM.My company has mitsubishi slow line cutting machine, spark machine, Taiwan peak processing center, engraving and milling machine, surface grinding machine and other dozens of precision mold equipment.The aluminum die-casting workshop is equipped with Hong Kong die-casting machines of 160 tons, 350 tons, 600 tons and 1,250 tons.The injection molding workshop is equipped with nearly 30 sets of plastic injection molding machines, with a maximum injection molding capacity of 6300g.In addition, there are CNC puncher, bending machine, drilling and milling and precision cutting equipment 120.Recently the company has imported three sets of Japanese painting equipment.Sophisticated equipment for the development of high-precision mold and high-grade products will provide a strong guarantee.

Our Service

1.Your inquiry related to our products or prices will be replied in 12 hours.

2.Individual formula according to customers' special drawing requests

3.Manufacturer with large capacity,ensures the fast production cycle after confirming the order.

4.Protection of sales area and private information for all of our customers.

5. Providing free samples + dimension inspection report + material report;

6. Checking raw material, and inform customer before mass production;

7. Informing customer production schedule weekly;

8. Arrange shipment, and Inform customer in advance 7 days before finishing the order;

9. Before shipment, send the detailed product pictures, dimension inspection report, material report to customer;

10.Delivery is on time.

Packing & Delivery