| Model: | - |

|---|---|

| Brand: | - |

| Origin: | - |

| Category: | Electronics & Electricity / Electronic Instrument / Analysis Instrument |

| Label: | dust analyzer , dust meter , gas analyzer |

| Price: |

US $22000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:03 Jan, 2019 |

Product Description

Product Overview

The DY-DT8000 wet dust measurement system adopts the measurement principle of laser front scattering. It is the closest online measurement for laboratory data, and is the best choice for dust measurement and low concentration dust measurement in wet flue gas. It is widely used in ultra-clean emission dust monitoring,Dust monitoring at the exit of the wet dust removal unit,etc.

Our factory focuses on production,R &D of gas analyzers for 13 years .You will get good performance products and the discount price of factory without distributor.

Measuring components:

dust concentration of gas

0~5/200mg/m³

Application

• Ultra-clean emission dust low concentration monitoring

• Dust concentration monitoring at the exit of the wet dust removal unit

• Monitoring of dust concentration at the outlet of a wet desulfurization unit, such as a waste incineration plant, etc.

• Suitable for dust concentration measurement of wet exhaust gases in different industrial processes

|

SPECIFICATIONS FOR DY-DT8000 gas dust analyzer |

|||

|

Measuring component |

dust concentration of gas |

||

|

Measuring range |

0~5/200mg/m³

Alarger range can be provided on request, and the intermediate value can be set freely. |

||

|

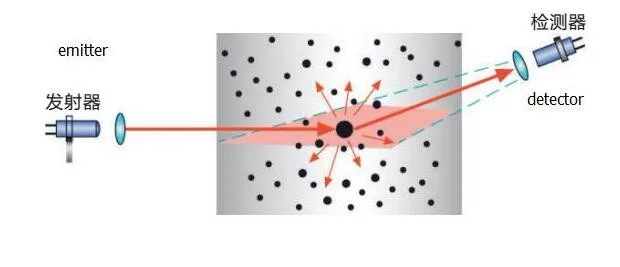

principle |

the principle that the intensity of scattered light is proportional to the concentration of dust

|

||

|

Medium temperature |

PVDF probe up to 120 ° C

Hastelloy probes up to 200 ° C (probes for higher media are available upon request) |

||

|

Flue gas pressure |

±20 mbar |

||

|

Measurement Accuracy |

±2% of the final reading |

||

|

Medium humidity |

Maximum 10g/m3 (mass component 1%) water vapor (please consult for higher water vapor concentration) |

||

|

Response time |

0.1~600 s; free to choose |

||

|

Protection grade |

IP65 |

||

|

Flow of sample gas |

4~20 m/s, (please consult the higher sample gas flow rate) |

||

|

signal Analog output |

Electrically isolated, 0/2/4~20 mA, maximum load 750 Ω; 10 bit, resolution ±1%

Optional second analog output, electrically isolated, 0/2/4 ~20 mA, maximum load 750 Ω, it can be set separately |

||

|

Relay output |

For status signal operation/fault, alarm, limit, maintenance

Load capacity: 250V, 1A; current limit |

||

| Interface

Switch input |

RS232 interface for notebook/desktop

The maintenance relay is turned on and the digital input is 1 |

||

|

Ambient Temperature

|

-20~+50°C (other temperature range needs to be equipped with outer casing) -20~+45°C (fan inlet air temperature) |

||

|

System components |

Sampling probe;Measuring unit (including transmitting/receiving device, measuring cell, heating cyclone, etc.);Evaluation unit;Fan |

||

|

Function check |

Zero and reference point automatic control

Pollution measurement |

||

|

Certification |

EN 61010-1 Electrical Safety

Measuring unit, the protection level of the fan is class I The protection level of the transmitting/receiving unit is class III The protection level of the transmitting/receiving unit is class III System: IP54;Electronic housing: IP65 |

||

Main Features

• low to medium dust concentrations measurement ,scattered light measurement principle.

• jet technology to extract some flue gas from the flue

• Continuous heating and insulation during the flue gas transmission process, to prevent measurement deviation caused by condensation

• Display operating values and system status on the LCD

•The flow rate of gas is controlled by the built-in pressure measuring device

• Reliable operation, automatic cycle check of zero value, reference value and measured value.humanized software,easy operation; integrated monitoring system,early maintenance warning.

• Low procurement and operating costs, minimal consumables and long life cycle

• Compact design, single side opening, single side mounting. Integrated sample gas extraction and return function with only one flange. An integrated measurement and control unit for easy installation , it allows the entire system to be mounted to a single bracket.

Principle

The instrument uses the principle of front scatter laser measurement. Since this principle is extremely sensitive, it is possible to detect very low particle concentrations.

System

The sample gas is pumped from the flue through the probe using a jet pump and transferred to a heated cyclone, to heat the flue gas to a superheated state (guaranteed above the dew point of the flue gas) and then to the measuring cell. The intensity of the scattered light is measured using a transmitting/receiving unit to obtain a dust concentration.

The exhaust gas is returned to the flue through the sampling probe. The instrument wind required for the jet is generated by the fan, which can also be used to clean the optical components of the purge launch/receiver unit.

Detailed Images

Packing & Delivery

|

MOQ |

1 set |

|

packing |

wooden box |

|

detail |

step 1:foam sheet wraps the product

|

| packaging can be customized

according to customer requirements |

About us

Company preview

Who are we?

Xi'an Dingyan Technology Co., Ltd.

We have been specialyzing in R&D, manufacturing gas analyzers for 13 years.

Our main products

Kinds of gas analyzers:

gas detecting and alarm analyzer, gas continuous emission analyzer, industrial process gas analyzer, gas chromatography

Measuring concentration of gases: Hydrogen (H2), Oxygen (O2), Sulfur Dioxide (SO2), Nitrogen oxides(NOx), Carbon monoxide (CO), Carbon Dioxide (CO2), etc.

Gases other parameters: humidity, temperature, pressure and the velocity, moisture

What can we give you?

1.Customize the appropriate solution for you.

2.High quality product

3.In time delivery

4.After-sales

Answer information online 2 hour within 4 hour to arrange technical guidance .

if required, we can provide On-site service of after-sales engineers.

7days*24h service (365days for customers)

5.Price

Factory direct sales to you without distributor.

Are you a long-term partner we are looking for?

Looking forward to meeting you!