| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Chemicals / Chemical Auxiliary & Catalyst / Chemical Auxiliary |

| Label: | chemical fillers , wear-resistant alumi , grinding alumina bal |

| Price: |

-

|

| Min. Order: | - |

| Last Online:23 Mar, 2019 |

Alumina Ceramic Grinding Column

High Alumina Ceramic Grinding Column

High Alumina ceramic Grinding column is used as grinding media for ceramic body and glaze preparation. It’s high purity and low abrasion loss make it to be suitable for both wet and dry superfine grinding of alumina, zirconium silicate, glaze, kaolin clay, quartz, feldspar, inks and ceramics in ball mill.

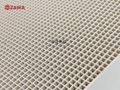

Product Features:

(1) Excellent wear and corrosion resistance; Chip-proof, acid-resisting, alkali-resisting, anti-abrasion, high thermal shock resistance

(2) High density and small thickness can increase the effective ground space and increase the yield;

(3) Low wear loss and long service life (it is 3-5 times compared with nature stone liner and 23 times compared with rubber liner),which can reduce the installation times;

(4) Main material is alumina which has no pollution to the grinding object,Easy to clean

(5) Shorten milling time and increase efficiency

Application:

1. Mainly used in ceramic, glaze, paint, zirconia silicate, aluminum oxide, quartz, silicon carbide, talc, lime carbonate, kaolin, titanium and other materials grinding, and mechanical equipment accessories.

2. Metallic minerals like copper, silver, nickel, gold, Zinc etc.

3. Non-metallic minerals like Calcium Carbonate, kaolin clay, zirconium silicate, TiO2 and other minerals.

4. White pigments, coatings, paints, inks etc.

5. Recommend to be used in stirred mill and ball mill.