| Model: | - |

|---|---|

| Brand: | Micet |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | 7BBL , Brewery , Craft beer |

| Price: |

US $50000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:18 Jul, 2019 |

7BBL brewery equipment for craft beer

Product Description

Configuration of 7BBL beer equipment

|

Name |

7BBL used brewery equipment for sale stainless steel fermentation tank conical fermenter |

|

Malt milling system |

-Miller with double roller , grist case, malt elevator. |

|

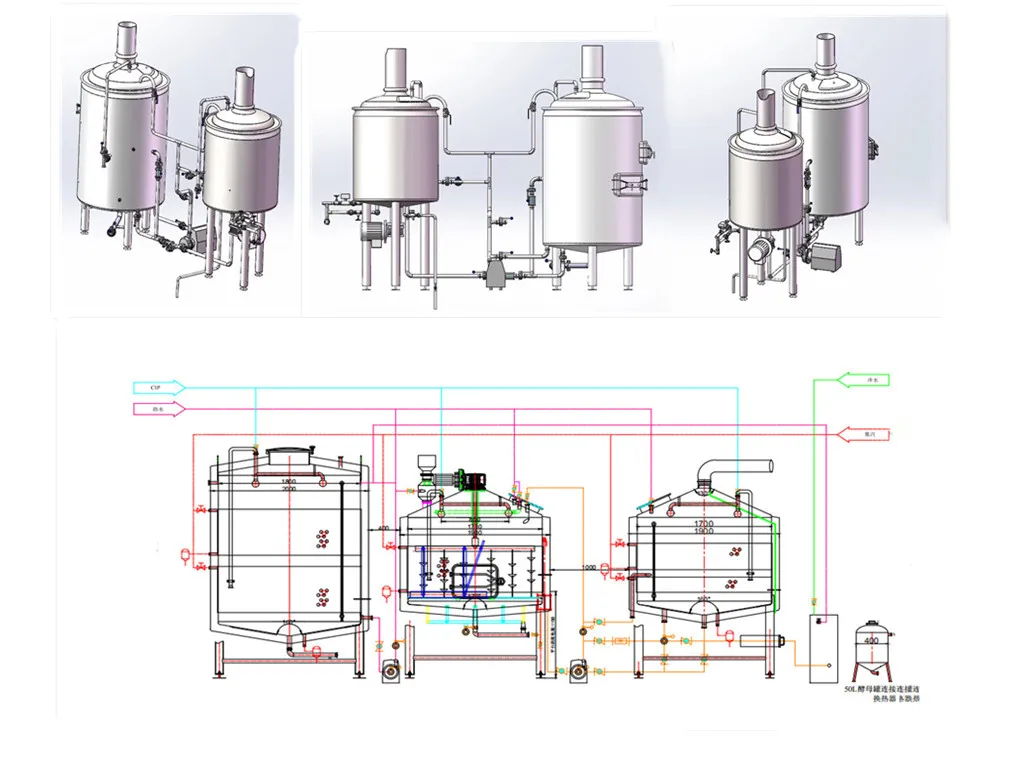

Brewhouse system |

-2vessel:Including Mash/Lauter tun, Kettle/Whirlpool tank.

|

|

Fermenting system |

-7BBLlFermentation tank

|

|

Cooling system |

Efficiency chillers or refrigerators with fryonto supply cooling energy.

|

|

Control system |

-PID semi-auto controller, PLC auto controller, brand is Siemens, Schneider,LG for optional.Electric components have Certificate.

|

|

CIPsystem |

-Sterilization Tank, Caustic tankThickness is 2mm.

|

Details

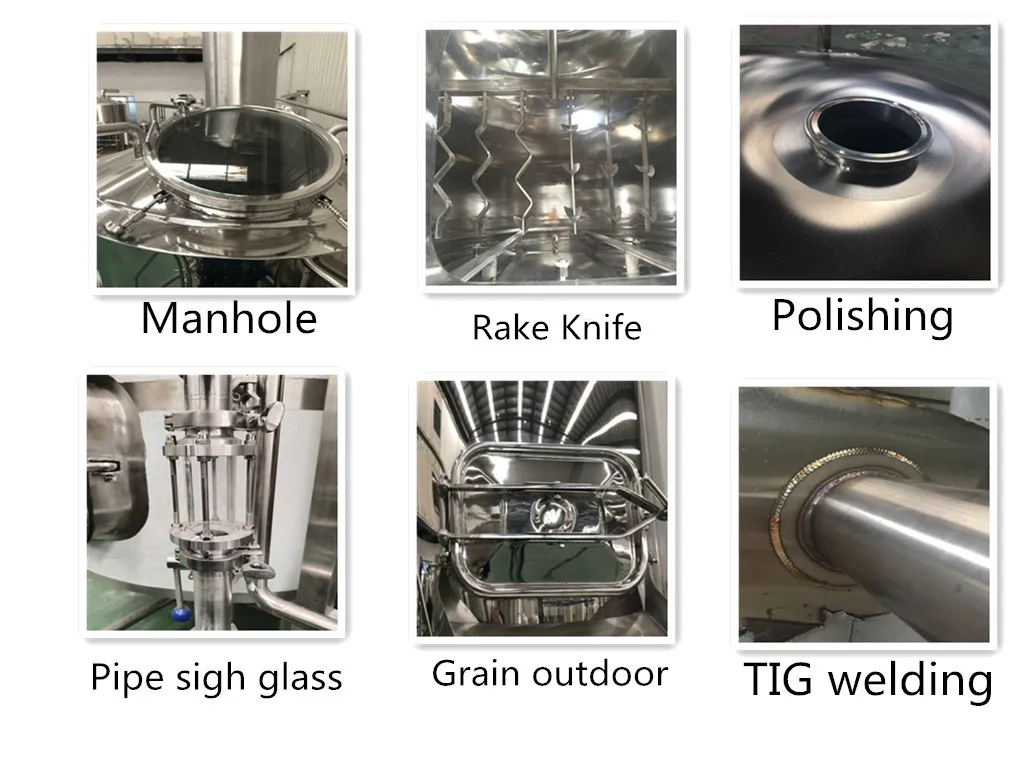

1. Welding & Polishing: 100% TIG welded joints and the interior is mirror polished to 0.2-0.4μm for stainless steel fermentation tank.

2. False bottom (filter plate), laser cutting T-wires, plate gap: 0.8mm; Material is SUS 304

This filter plate is made on a complete stainless steel by CNC lathe, it is strong, filter fast and leak no any grist.

3. The wort pump can be controled and adjust the rate accurately.

4. 7BBL used brewery equipment for sale equipped with hops filter, it can filter the impurity, clear the wort.

5. Full set of stainless steel ice water pipe, durable and beautiful.

Manufacture Details

Features:

1)Fully insulated mash tun and brew kettle mounted on a modular, radius edge, stainless steel under-frame, designed for easy and efficientinstallation in almost any structure.

2) 100% certified 304L sanitary food grade stainless steel in all of our components. Zero mild steel in our brewhouse, kettles or brew deck.

3) A Mash out manway and true Vee-Wire False Bottom for rapid and efficient cleanup.

4) A Design that allows infinite control, endless flexibility and precise repetition.

5) All necessary equipment to monitor the quality of the brew.

2.Fermentation system

Here yeast is added to wort to create the distinctive composition and flavor of beer. Our special design allows for fermentation, aging, carbonation and lagering all in one tank, if desired. This saves the brewer time and minimizes space. Fermenters are individually temperature controlled. (ASME Code Approved Optional.)

1)100% certified 304 sanitary food grade stainless steel in all of our components. Zero mild steel in our fermenter and BBT tanks.

2)360 Spray ball for effective CIP cleaning

3)Manway for easy access to the interior of the tanks (for cleaning or inspection)

4)Safety Pressure valve to protect the tanks from being over pressurized or creating negative pressure.

5)Accessible sampling valve for beer monitoring

6)Carbonation / Aeration Stone

Our Service

1.Pre-sale

• Layout Design

Welcome to share your location drawing or size with us if you confirmed it. We have professional technical team who will help to design you the suitable layout accordingly.

• Tank drawing Design

Both of the tanks and piping are available to be customized.

Please feel free to share your ideas with us, we will try our best to offer you the best solution and design accordingly.

• 3D Drawing Design

It is available to design you the 3D drawing or layout accordingly if you have already confirmed your building.

2.After-sale

• Report the process and details

We can provide weekly production report to let you clear of production progrss and production details;

• Test report

We will do equipment test and test report available for you;

• English operation manusls

Providing piping connection drawing and English operation manuals;

• Installation and training

Providing equipment installation, deb ing, and personnel training service;

• Warranty for 36 months

Main machine guarantee for three years; Accessories and electronic components will have one year free warranty; Supply lifetime maintenance and technical service.

Company information

MICET is a professional manufacturer of beer brewing equipment and located in the famous industry city Jinan City. Our team has 10 years experience in brewery setup for brewpub, bar, restaurant,microbrewer and regional brewery. We focus on high-end product line and insist on craftsman spirit, perform strict quality control and process testing in production to ensure that customers have good expectations for equipment and on-time delivery.

Our welding are all full welding by water, uniform dimpled steam and cooling jacket to ensure no leaking and long life, welds passivated! Our polishing are overall mirror polishing without any welds left.

Packing & shipping

Beofre shipping, our inspection department will check the equipment the last time according to the order equipment list and drawings to make sure all is right in the lcients requirements; The shipping department will work out the checking list and pack them in wooden box; All tank ports with a plastic cover to prevent dust;

Tanks on cradle must be secure with bolts.

The cradle and tanks will be fixed to container by steel wires.