| Model: | - |

|---|---|

| Brand: | YMX |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Wire Mesh |

| Label: | - |

| Price: |

-

|

| Min. Order: | 5 pc |

| Last Online:02 Sep, 2019 |

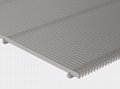

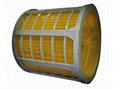

Wedge Wire Screen Panel Sieve Bend Screen Sieve Bend Screen Wedge Wire Screen

PRODUCT FEATURES

The wedge wire sieve bend screen, also known as the run down screen, de-watering screen, side hill screen, DSM screen, Parabolic screen,?curve screen, etc, is the pressure bend sieves. The curved bend screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

The dimensions, wire diameter, slot and frame structure can be customized.

Pressure Bend Sieve is a kind of very efficient sieve which can effectively improve powder extraction rate and starch quality, and thus has an obvious economic benefit.

Typical uses of the sieve bend screens are sewage treatment, laundry wash water clean-up, poultry, fish, fruit and vegetable wastewater processing, minerals processing, coal preparation, paper production, textile plants, and many more. A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow.

Main Features of Wedge Wire Sieve Bend Screen

1) Lateral Strength

Increases rapidly with the width of the profile and sufficient is needed to avoid the likelihood of the wedge wire screens being bent sideways and the accuracy of the slot being thereby lost.

2) Vertical Strength

Increases rapidly with the depth of the profile. And it is needed to a greater degree than is lateral strength.

3) Better Filtration

Due to specialize manufacturing process, wide range of slot opening is available down to 0.15mm to allow proper slot selection depending upon the size of sand in particular area. This gives better sand control and reduced pump maintenance and longer tube well life.

4) Long Wearing Life

With abrasive materials the top surface of the profile becomes worn away and inevitably the aperture must increase. With a small angle of opening the increase is gradual, but with a large angle it is rapid. The apertures quickly reach the oversize limit and the working life is reduced.

5) Non Clogging Slots

V-Shape wire which gives inwardly widening V-Shape slots. This shape doesn’t give space for any sand particle to get stuck inside the slot and these screens are non clogging. Hence, the efficiency of tube well isn’t reduced over years due to clogging.

Standard Sieve Bend Screen PARAMETER

|

Length Range |

Up to 6000mm |

||||||

|

Width Range |

Up to 6000mm |

||||||

|

Slot Range |

20 micron to 3000 micron (Tolerance:+-5 micron) |

||||||

|

Wedge Wire |

0.5x1.5 |

0.75x1.5 |

1x2 |

1.5x2.5 |

2x3 |

2x4 |

3x5 |

|

Support Rod |

1.5x2.52x3 |

1.5x2.52x3 |

1.5*2.52x3 |

2x3 |

3*5 |

3x5 |

3x54*65*8 |

|

Angle |

90°,120°,140°,150°,160° ,180°etc. |

||||||

|

Arc height |

10mm,15mm,20mm,50mm or depend on you size of screen panel. |

||||||

|

Frame |

No frame or ” L” type frame, ordinary frame, 5*10mm frame etc, according to your request. |

||||||

YMX FILTER MANUFACTURING CO., LTD is a custom fabricator of series of wire screen, cone strainers and woven wire cloth products. For more than 20 years' experience, we are serving customers from a wide range of industries from all over the world.

If you are interested in custom wire screen, you can click here to browse our website.

| Payment Terms: | T/T 30%-50% in advance |

|---|---|