| Model: | CEMA |

|---|---|

| Brand: | Binxin |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | rubber belt conveyor , Conveyor Idlers , Carrying Rollers |

| Price: |

¥54

/ pc

|

| Min. Order: | 50 pc |

| Last Online:05 Nov, 2019 |

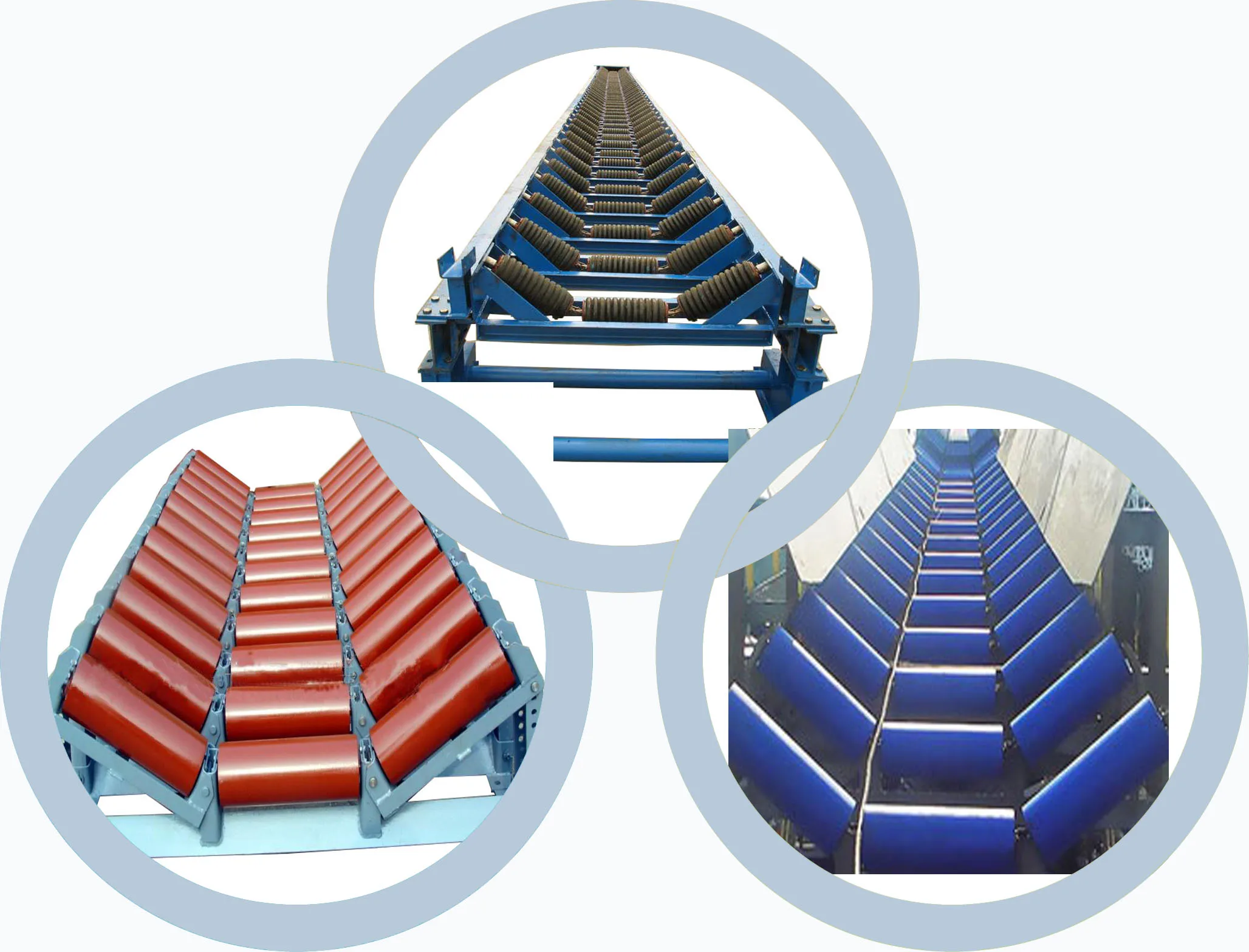

Conveyor rollers, which are important parts of belt conveyor, can support conveyor belt and materialweight.It accounts for 35% ofthe total cost of a belt conveyor and generates more than 70% of the resistance, so the quality of idlers is particularly important.

Pipe: Q235 - carbon Steel.

Shaft: Q235, 45# - carbon Steel.

Diameter:60mm-219mm

Seal: Labyrinth seal, TK or DTII, can do as your request.

Bearing: HRB, SKF, FAG deep groove ball 2RS bearing, also can be done as your request.

|

Product Name |

High Quality Steel Pipe Belt Conveyor Roller |

||

|

Material |

Steel,PVC,HDPE,UHMWPE |

||

|

Belt Width |

400-3000mm |

||

|

Bearing |

Single & Double Row Deep Groove Ball Bearing 2RZ&2Z with C3 clearance |

||

|

Color |

as per customers' requirements |

||

|

Service Life |

More than 30000 hours |

||

|

Application |

Coal Mining, Power Plant, Cement,port,etc. |

||

|

Production capacity |

2000pcs/day |

||

| Standard Diameter

mm Inch |

Lengthscope (mm) |

Bearings Type

(Min-Max) |

Idler's shell wall thinkness |

|

|

63.5 |

21/2 |

150-3500 |

204 |

3.0mm-3.75mm |

|

76 |

3 |

150-3500 |

204 205 |

3.0mm-4.0mm |

|

89 |

31/3 |

150-3500 |

204 205 |

3.0mm-4.0mm |

|

102 |

4 |

150-3500 |

204 205 305 |

3.5mm-4.0mm |

|

108 |

41/4 |

150-3500 |

204 205 305 306 |

3.5mm-4.0mm |

|

114 |

41/2 |

150-3500 |

204 205 305 306 |

3.5mm-4.5mm |

|

127 |

5 |

150-3500 |

204 205 305 306 |

3.5mm-4.5mm |

|

133 |

51/4 |

150-3500 |

204 206 207 305 306 |

3.5mm-4.5mm |

|

152 |

6 |

150-3500 |

204 206 207 305 306 307 308 |

4.0mm-4.5mm |

|

159 |

61/4 |

150-3500 |

204 206 207 305 306 307 308 |

4.0mm-4.5mm |

|

165 |

61/2 |

150-3500 |

207 305 306 307 308 |

4.5mm-6.0mm |

|

194 |

75/8 |

150-3500 |

207 307 308 309 310 |

4.5mm-6.0mm |

|

219 |

85/8 |

150-3500 |

308 309 310 |

4.5mm-6.0mm |

Detailed Image

Advantages

1.Easy installation ,stable operation ,good flexibility and min 30,000 hours stable lift time.

2.High accurate steel pipes ensure the rollers with wearing resisting,low vibration and noise.

3.Sealing arrangement include a double seal.

4.Dustproof, waterproof and anti-alkali and acid suitabe for corrosion environment.

5.Electrostatic spraying technical makes the roller more durable and good-looking.

Application

1.Chemical Industry

2.Fertilizer, Salt, Sugar, Pulp Paper, Acid and Alkaline, etc.

3.General Industry

4.Coal Mining, Cement, Concrete, Limestone and Quarry, etc.

5.Operating Condition

Our factory

Our factory

Delivery & Shipment

Delivery & Shipment

| Payment Terms: | TT / LC |

|---|---|