| Model: | - |

|---|---|

| Brand: | huanpai |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | - |

| Price: |

¥21000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:07 Jul, 2023 |

Our Company

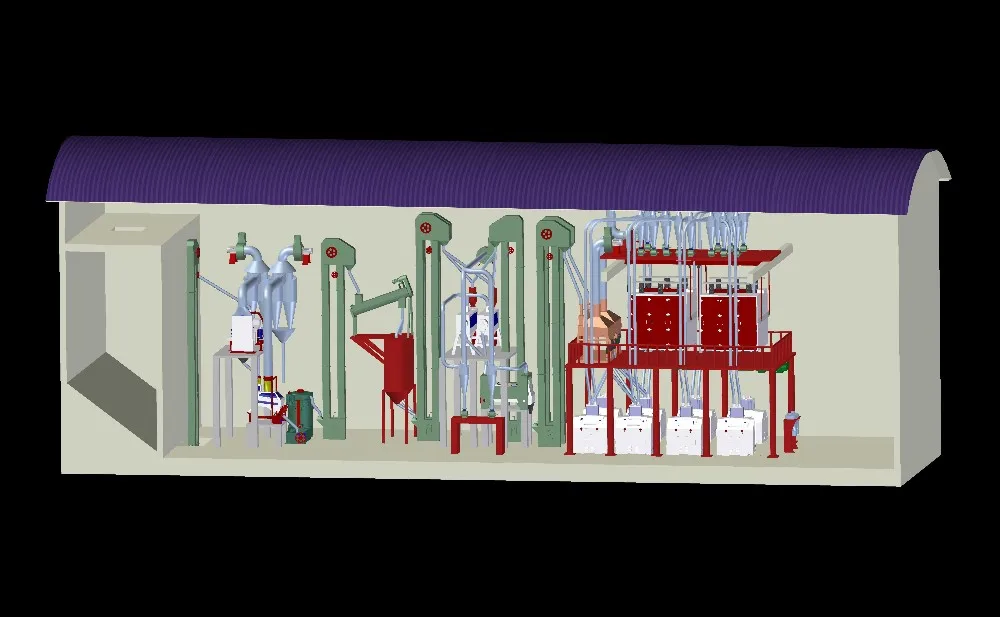

Shijiazhuang Huanpai Machine Co.,Ltd is a professional manufacturer of all types of flour milling machine for wheat/maize/corn, Our production capacity is from 10 ton to 500 ton per day. We provide turnkey project of our machienry, including special design, installation instruction, commissioning and training workers.

Our products are exported to Australian, America, Canada, Belgium, Egypt, Algeria, Zambia, Congo, Kenya, Ethiopia, Uganda, Yemen, Tanzania, Tajikistan, Afghanistan, Vietnam, Israel, Mozambique,Kazajastan and other country.

We have been in this field for more than 50years, and has grown into a a large supplier of feed machine with engineering automation control technology, product research, development and manufacturing, projects design and installment. Our equipment is widely exported to more than 30 countries and regions. Our professional engineers can design the machine as per your requiremnt. The complete set feed machine is suitable to small, middle and large feed plant to make feed powder, feed pellet for chicken, fish, sheep, cow etc.

Factory

Warehouse

Workshop

Workshop

Product Description

1. The clean part:

To clean out the middle and small impurity from wheat,corn,maize. e.g., dust, stone, magnetic material, wheat,corn,maize was bitten by insect and so on. Includes beating, screening, destoner, magnetic separator and dampening.this section is make the wheat,corn,maize to prepare for millling part and to protect the machinery as well.

2.The flour milling part:

Include different number of mill and sifter to mill the wheat,corn,maize and separate the flour and bran

(1) Mill: mill the wheat,maize,corn to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to enssure flour quality.

3.Packing part

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

Main Features

1.Automatic whole line can save workers, one person can be availbale for operation.

2.Complete function precessiong as cleaning wheat, corn maize, peelling maize, and grinding wheat, corn maize into wheat,maize corn flour and maize corn grits and wheat,maize bran.

3.Clean wheat,corn maize to remove stone, metal, sand and all sorts of impurities.

4.Peel maize to remove maize skin, remove maize germ, remove black maize hilum. After cleaning and peeling, it prepares best maize material for further processing into maize flour or grits.

5.You can choose the mesh to make the flours fine as you requirement.

6. Simple structure in linear type ,easy in installation and maintation.

7. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

8. High pressure double crank to control the die opening and closing.

9. Running in a high automatization and intellectualization,no pollution

10. Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Certifications

Packing & Delivery

Our Service

Pre-sale service.

* Inquiry and consulting support.

* Special design.

* View our Factory.

Installation services

An experienced engineer will be send to project site to ensure the successful completion of each phase of the plant, which enables us to provide professional consultation, design, manufacture, installation and project management services.

Contact Us

Contact Name:Mary Feng

Mobile (whatsapp):0086 18603267115

http://www.huanpaimachine.com