| Model: | XM500 |

|---|---|

| Brand: | Shisheng Machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | Briquette Machine , Fly Ash , Briquetting |

| Price: |

US $3000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:02 Aug, 2024 |

Feeding Size: <5mm

Capacity: 1-50T/H

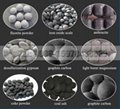

Raw Material: fly ash, coal gangue, soft coal, anthrocite coal, charcoal dust, coke fines, bauxite, etc.

Application: Refractory, power plant, metallurgical, chemistry, energy, transportation and heating, etc.

Introduction:

Charcoal Ball Press Machine is also called powder material molding machine, it is used to briquette fly ash, coal gangue, soft coal, anthrocite coal, etc. Belongs to cold briquetting technology; In production, it can produce popular briquette shapes, like oval shape, pillow shape and square shape, etc. in high density, strong strength and high hardness through adding some kind of binder material, so customers are more like it. Its structure is composed of three parts: feeding system, transmission system and briquetting system. XM290 model is often as a trial machine goes to customer site for small size and easy maintenance.

(1) Charcoal Ball Press Machine is also called powder material molding machine.

(2) It can produce popular briquette shapes, like oval shape, pillow shape and square shape, etc.

(3) Finished briquettes are in high density, strong strength and high hardness.

(4) Fly ash briquette machine is composed of three parts: feeding system, transmission system and briquetting system.

Cell: 0086-15978436639

Email: lixingchen0822@126.com

Charcoal Ball Press Machine Working Principle:

(1) Through reducer transmitting the powder material to two rollers, and making them rotated in opposite directions.

(2) The powder materials naturally enter into the roller molds.

(3) When the materials rotating to two rollers line contact points, materials pressure reached a peak.

(4) Under enormous pressure, the powder materials are suppressed into finished briquettes.

| Model | Reducer | Ratio | Roller Size (mm) | Main Shaft Speed (r/min) | Matched Power (kw) | Capacity (t/h) | Pressure Type |

| XM290 | ZQ350 | 1:31.5 | 290*200 | 12-14 | 5.5 | 0.9-1.0 | Mechanical |

| XM360 | ZQ350 | 1:31.5 | 360*250 | 12-14 | 7.5 | 1.5-2.0 | Mechanical/Hydraulic |

| XM400 | ZQ400 | 1:31.5 | 400*250 | 12-14 | 7.5 | 2.5-3.5 | Mechanical/Hydraulic |

| XM430 | ZQ400 | 1:31.5 | 430*250 | 12-14 | 11 | 3.5-4.5 | Mechanical/Hydraulic |

| XM500 | ZQ650 | 40.17 | 500*470 | 10-12 | 37 | 7.5-8.5 | Mechanical/Hydraulic |

| XM650 | ZQ850 | 40.17 | 650*470 | 9-11 | 45 | 9-10 | Mechanical/Hydraulic |

| XM750 | ZQ1000 | 48.57 | 750*570 | 9-11 | 90 | 13-14 | Mechanical/Hydraulic |

| XM850 | ZQ1250 | 50 | 850*570 | 8-10 | 110 | 15-17 | Mechanical/Hydraulic |

| Remarks | 1. Above capacity is based on coal density 0.8, briquette size Φ50*33mm. | ||||||

| 2. Roller material is 65Mn, High chromium alloy and 9Cr2Mo. | |||||||

| 3. According to different material, parameter will change slightly. | |||||||