| Model: | - |

|---|---|

| Brand: | Kangfa |

| Origin: | Made In China |

| Category: | Packaging , Printing & Paper / Packaging Materials / Plastic Packaging Materials |

| Label: | laminating film , adhesive bopp film , packaging material |

| Price: |

US $3000

/ Ton

|

| Min. Order: | 2 Ton |

| Last Online:24 Jun, 2020 |

Matt:

Bopp thermal lamination film(Glue)

|

SPECIFICATION |

24G GLOSS |

25G GLOSS |

27G GLOSS |

30G GLOSS |

26M MATT |

28M MATT |

30M MATT |

|

|

|

|

|

|

|||||||||

|

THICKNESS {µm} |

TOTAL |

24 |

25 |

27 |

29 |

26 |

28 |

30 |

|

|

|

BASE |

12 |

15 |

17 |

17 |

15 |

17 |

18 |

|

|

|

|

EVA |

12 |

10 |

10 |

12 |

11 |

11 |

12 |

|

|

|

|

WEIGHT |

m²/kg |

45.04 |

43.48 |

40.05 |

37.27 |

42.37 |

39.25 |

36.63 |

|

|

|

Kg/m² |

0.0222 |

0.023 |

0.02497 |

0.02683 |

0.0236 |

0.02548 |

0.0273 |

|

|

|

|

WIDTH{mm} |

360 390 440 540 590 780 880 1080 1320 1400 1600 1880 {or as customers request} |

|

|

|||||||

|

|

|

|||||||||

|

LENGTH{m} |

200-3000 |

|

|

|||||||

|

|

|

|||||||||

|

PAPER CORE |

25.4mm{1 inch}. 76mm{3 inch} |

|

|

|||||||

|

|

|

|||||||||

|

BONDING |

LESS THAN 2 |

|

|

|||||||

|

|

|

|||||||||

|

TENSILE STRENGTH |

MD:2.4×106 dyne/cm CD:5.3×106 dyne/cm |

|

|

|||||||

Process parameter:

Equipment for laminating film: dry and wet film laminator

Temperature: Normal :85~100oc

Special:100~110 degree

Roller pressure :10~18 Mpa

Speed :8~50 m/min

Remarks :Special laminations refer to those with thicker ink, solid color, high moisture content and bigger size paper.

Applications:

1.Blueprint document,spray paintings,digital print

2.Cosmetic,gift medicine,liquor,etc

3.Promotional materials,photo album,catalogs,pictures,wedding photograph,coating on books and magazines,paper bag,non-drying adhesive,clothes lag

bopp lamination film

Environmentally friendly

It is environment friendly, non-hazardous to health and safe to use as no toxic gases or volatile content is emitted. Safety in laminating process as no solvent based adhesive is used.

Easy handling

It's easy to operate once the required temperatures is met and no special technique required.

Efficient and energy-saving

Production cost is reduced substantially as there is no film wastage, mixture of adhesive solvent, and no UV heating lamp is required.

High function

Compared with other solvent lamination, our film is better in clarity and bonding. Strong ability of absorbing powder. It prevents lamination from being pressed, bubbled and shredded off easily. Matt thermal lamination film is good for spot UV and hot stamping.

Application

Production Process

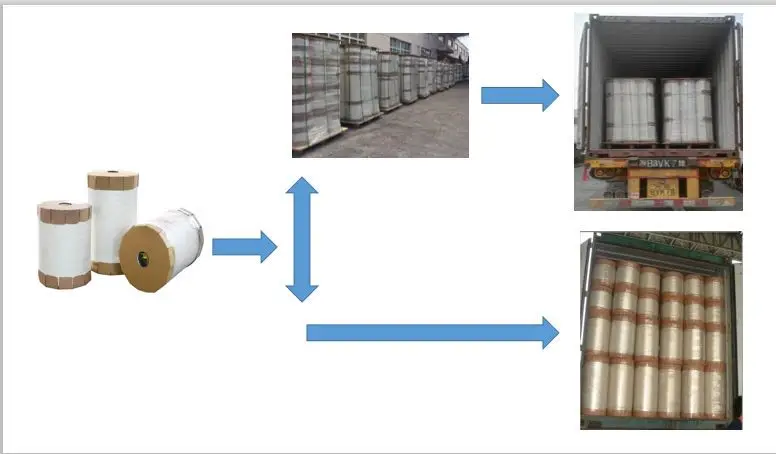

Packing & Delivery

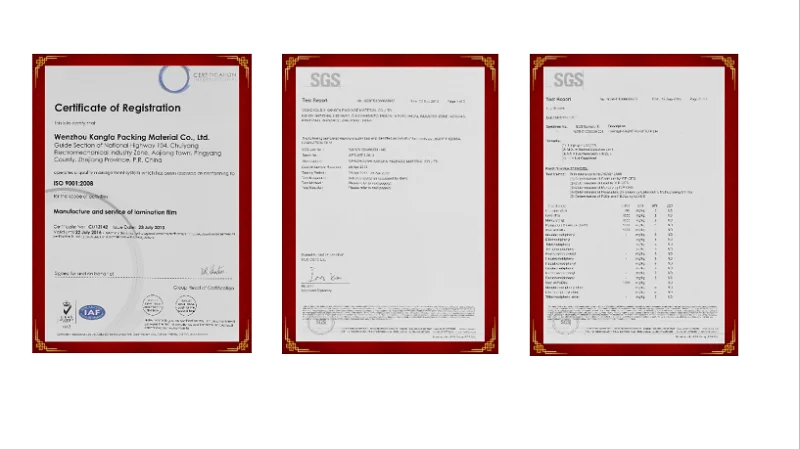

Certificate