| Model: | 127kw |

|---|---|

| Brand: | ZSHC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | Tube mill , pipe making machine , pipe making factory |

| Price: |

US $180000

/ set

|

| Min. Order: | 1 set |

| Last Online:27 Aug, 2022 |

1. Quick Details

Applicable Industries: Manufacturing Plant, Retail, Construction works

After Warranty Service:

Core Components:PLC, Engine, Bearing, Motor

Condition:New

Type:Pipe Production Line

Pipe Material:Carbon Steel

Application:Drain Pipe

Production Capacity:96%

Place of Origin:Hebei, China

Brand Name:ZSHC METOWD

Voltage:380V/415V/440V

Power(W):127

Warranty:1 YEAR

After-sales Service Provided:Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Key Selling Points:High Productivity

Product Name:Tube mill

After-sell service:Field Installation

Pipe diameter:48-127mm

Color:Custormized

Pipe application:Construction Tubes

Pipe shape:Round Shape

Thickness:1.5-5.0mm

Function:Making Tube Body

Package:plywood cases

Speed:60-70m/min

2. Packaging & Delivery

Packaging Details

1.Export Wooden Package

2.Free Fumigation Certification

3.Pallet for Fork Truck

4.Mark as buyer's requirement

Port :Xingang, China

3. Product Description

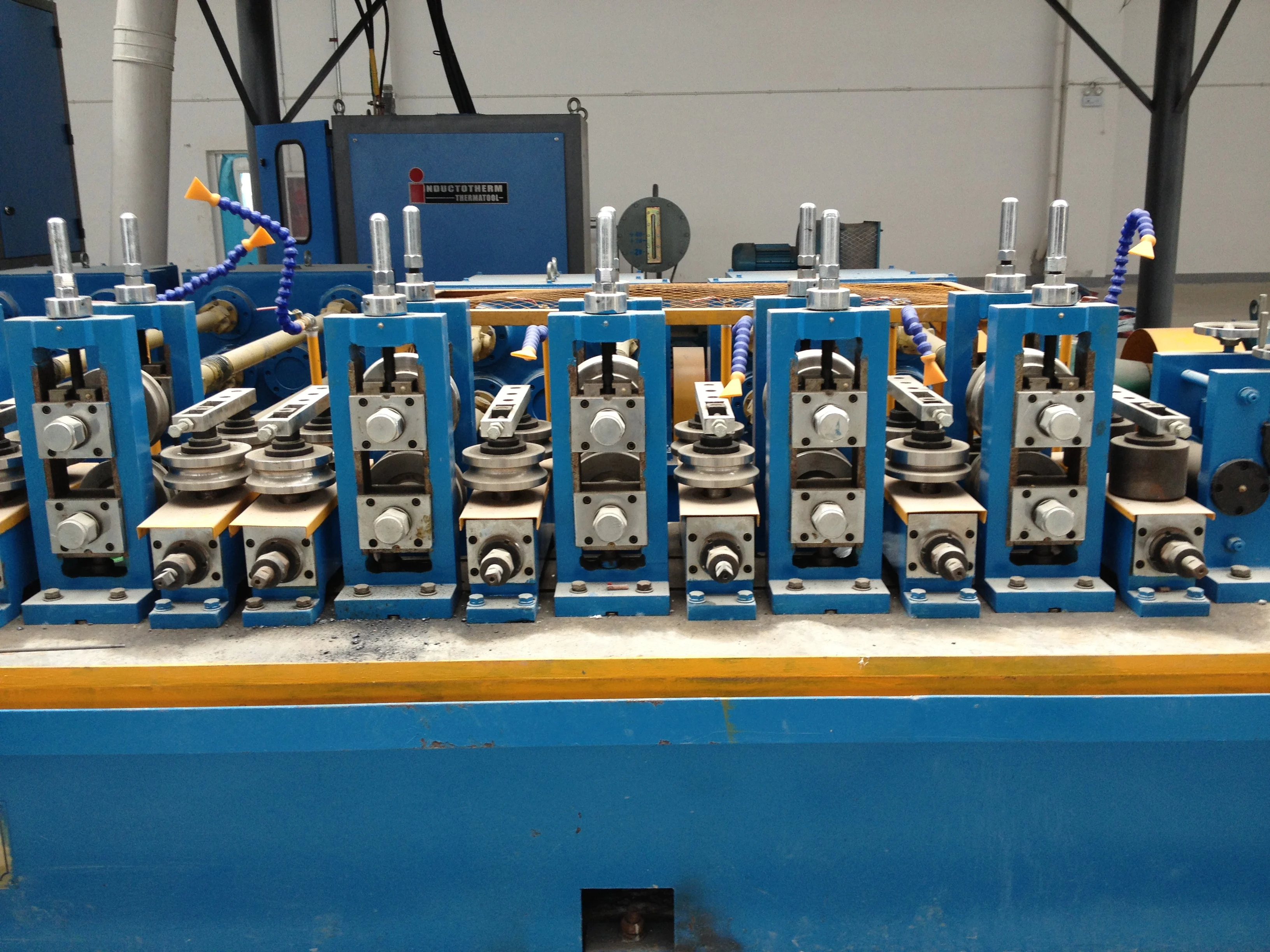

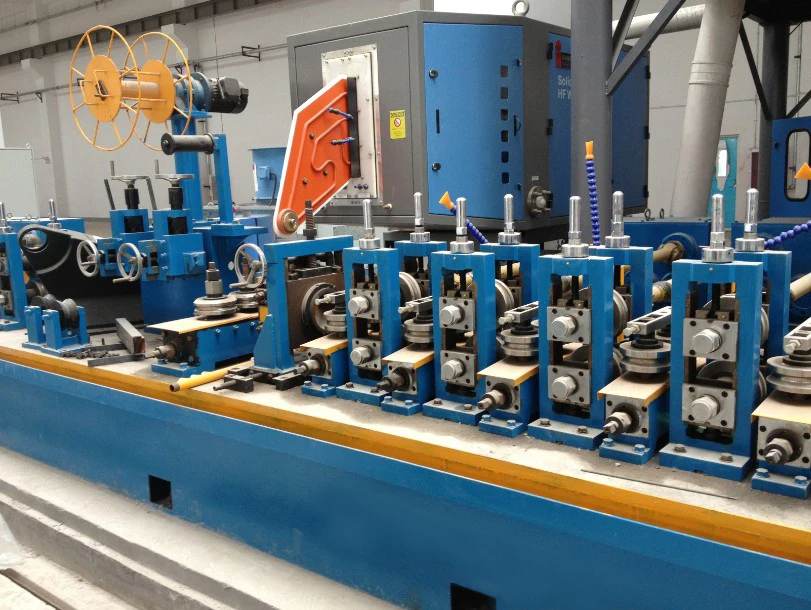

The φ127mm welded pipe making line is used to produce steel pipes of φ48mm-127mm in OD and 1.5-5.0mm in thickness, as well as corresponding square and rectangular pipe. The welded pipe making line from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.Finished product will be of round, square or rectangular pipe.

Process flow

{Steel strip}→→ Double-head un-coiler →→Shear and welder→→Horizontal accumulator→→Forming mill→→HF solid state welding→→Cooling→→Burr removing→→Sizing and Turks head→→Cutting saw →→ Run-out table

The advantages of the welded pipe making line

1. High production efficiency, line speed can reach up to 70m/Min.

2. High Strength, the line works stably at a high speed, which improves product quality.

3. High good product rate, reach to 96.5%.

4. Siemen, Yaskawa, Allen-Bradley motors as option.

Detail Conditions:

| Finished Product | Round Pipe |

φ48-127mm Thickness 1.5-5.0mm

|

| Square&Rectangular Tube |

40*40mm-100*100mm, Thickness 1.5-4.5mm |

|

| Length | 5m-12m | |

| Length Tolerance | ±1.5mm | |

| Production speed | Max 70m/min | |

| Raw material | Coil material |

HR/CR Carbon steel or galvanized steel High strength low-alloy-steel(HSLA) Advanced high strength steel(AHSS)

|

| Width | 150-400mm thickness 1.5-4.5mm | |

| Coil ID | φ 580-630mm | |

| Coil OD | φ900-2000mm | |

| Coil Weight | 5.0-6.0Tons |

4. Company profile

ZSHC Mechanical & Electrical Equipment Co., Ltd. was established in 2009, covering 20,000 square meters, with more than 100 employees. It has developed into a comprehensive enterprise integrating R&D, production, sales and service.

As one of the global induction heating and welding manufacturer specializing in tube and pipe welders, ZSHC provides the widest range of HF Welders available.

The ZSHC Compact High Frequency Welder provides a great solution for those older tube mills with limited tube diameter ranges while benefiting the producer in terms of reliability, compact layout, safety and supportability. This simplified and compact design fits the traditional DC power supply into the RF Generator cabinet, making this welder the logical choice for a cost effective installation. The Compact welder is ideal for quick retrofitting on existing mills when replacing obsolete vacuum tube welders. All the reliability of a standard ZSHC Compact High Frequency Welder, with a small footprint.

All of our welders are based on the High Frequency or “HF” welding process that we developed almost 60 years ago and have led the way ever since. With its Current-Fed Inverter (CFI) design, our welding equipment range gives you the capability to successfully weld almost any metal you want – efficiently and economically.

We supply equipment needed to weld carbon and stainless steel, brass, copper, and aluminum, as well as exotic alloys, such as boron steel and HSLA, AHSS, and Trip Steels

5. Customer visit

6. Exhibition

7. Recommended Products