| Model: | - |

|---|---|

| Brand: | victory |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | sand making , VSI sand making , mining machinery |

| Price: |

US $3500

/ set

|

| Min. Order: | 1 set |

| Last Online:24 Jul, 2020 |

Product Introduction

VSI series vertical shaft sand making machine is designed as a multipurpose crusher with variety of feeding and crushing mode after get many feedback fromclients and operators, so we make production increased, wear costs reduced, maintenance extended. VSI vertical impact crusher becomes the preferredequipment in the field o 'stone shaping, sand making, refractory materials and industrial products etc.

Performance Features

1.self crushing and hammer crushing 2 types for dferent purpose.

2. Normally only one oil pump work,but when the pressure & flow rate areless than the set value, or when the first pump stop running. the secondpump works automatically to esure the normal operation of VSI Crusher.

3.Hydraulic maintenance boom reduced maintenance costs ftively.

4.Bearing keep constant temperature, the oil pump circle automaicallytoensure that the tempersture of the bearing cylinder and tank oill is similar50 a to prevent freezing in winter.

Working principle

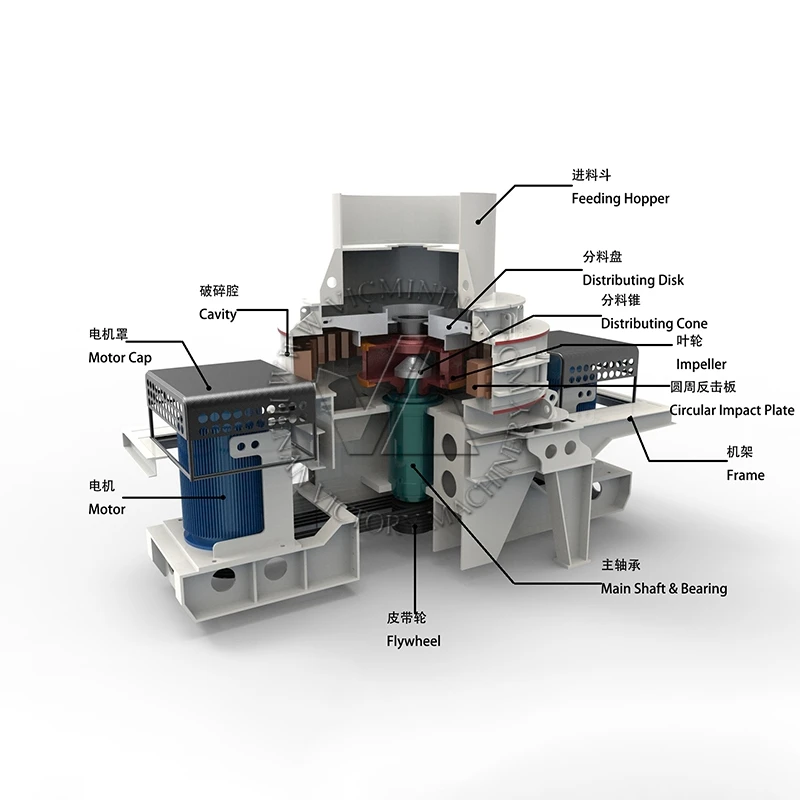

VSI vertical impact crusher crushes materials by high-speed movement andfriction between the materials. The materials .fall into the crusher, throughthe fedig hopper then go into the separating plates and diwided into twaparts. One part enters into the high-speed rotating swing wheel from themiddle of the distributor, which is accelerated rapidly in the swing wheel,and then ejects from the runner af the swing wheel athigh speed. First, itimpacts and breaks with another part of materials falling around thedistributor, and then it impacts on the material lining of the crushing chamber together, and then move down after changing the direction. Thematerials are discharged from the flowing channels of the impeller and forma continuous material curtain, so the material are finished to be crushedafter being impacted, rubbed and ground many times in the crushing chamber. The finished materials are discharged from the crushing chamberand go into the discharging hopper oflow chassis under the force of gravity.

Parameters

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | VSI-6X1150 |

VSI-6X1263 |

|

|

Capacity (t/h) |

Center and Sides Feeding |

120-180 |

200-260 | 300-380 | 450-520 | 500-640 | 400-450 | 550-600 |

| Feeeding at center | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | 350-400 | 450-500 | |

|

Max. Feedeing Size (mm) |

Soft material | <30 | <35 | <40 | <40 | <40 | <50 | <50 |

| Hard material | <25 | <30 | <35 | <35 | <35 | <40 | <45 | |

|

Roating Speed (r/min) |

1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | 1000-1300 | 900-1000 | |

| Double Motor Power (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 400-440 | 250-300 | 300-350 | |

| Power Source | 380V 50HZ | |||||||

| Hydraulic Oil Pump |

Motor Power (kw) |

2*0.31kw | ||||||

| Safety Protection | Complementary double pump to ensure the oil supply, stopautomatically if there is no flow or no hydraulic pressure of oil; cooled water, moter heating start in winter | |||||||

|

Dimension (mm) |

820*520*1270 | |||||||

| Power of Tank Heater (kw) | 2kw | |||||||