| Model: | F24-F220 |

|---|---|

| Brand: | HAIXU ABRASIVES |

| Origin: | Made In China |

| Category: | Industrial Supplies / Tools / Abrasives |

| Label: | Green Silicon Carbid , Blasting Titanium Al , Green SiC |

| Price: |

US $1710

/ Ton

|

| Min. Order: | 1 Ton |

| Last Online:18 Oct, 2023 |

Green Silicon Carbide For Blasting Titanium Alloy

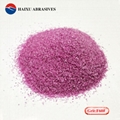

Green silicon carbide is characterized by extreme hardness (Mohs 9.4/2600 Knoop) which only rank after CBN and B4C.

Green Silicon Carbide (SiC) is an extremely hard (Mohs 9.4 / 2600 Knoop) man made mineral that possesses high thermal conductivity and high strength at elevated temperatures (at 1000°C, SiC is 7.5 times stronger than Al2O3). SiC has a modulus of elasticity of 410 GPa, with no decrease in strength up to 1600°C, and it does not melt at normal pressures but instead dissociates at 2600°C.

Green silicon carbide is widely used for surface treatment such as abrasive blasting, sand blasting, lapping, microlapping, polishing, grinding, etc.

Green Silicon Carbide For Blasting Titanium Alloy Description:

Green Silicon Carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke. It is a synthetic brittle carborundum with high thermal conductivity and high strength which get no decrease in 1000℃ ( 7.5 times stronger than Alumina)

Green Silicon Carbide For Blasting Titanium Alloy Characteristic:

Extremely high hardness

High wear and hardness resistance

High strength, high temperature resistance

High temperature strength

Green Silicon Carbide For Blasting Titanium Alloy Applications:

|

PZT/ Piezoelectric ceramicPolishing |

F240,F1000 |

|

Polishing Quartz glass |

F80,F120,F280,F360,F500,F600,F800 |

|

Titanium products / Titanium alloy kitchenware |

F120 |

|

Polishing Marble, Granite |

F46,F60,F80,F120,F180,F220,F280,F320,F360,F400, F500,F600,F800,F1000 |

|

Blasting carbide alloy cutting tools |

F24,F46,F120,F220,F280,F320 |

|

Lapping thin brittle material precise component |

F360,F400,F800,F1000 |

|

TYPICAL CHEMICAL ANALYSIS |

|||

|

Chemical Content |

F20-F220 |

F230-F2000 |

|

|

SiC |

Min 99% |

Min 98.5% |

|

|

SiO2 |

Max 0.50% |

Max 0.70% |

|

|

F,Si |

Max 0.20% |

Max 0.40% |

|

|

Fe2O3 |

Max 0.10% |

Max 0.15% |

|

|

F.C |

Max 0.20% |

Max 0.30% |

|

|

L.O.I |

Max 0.05% |

Max 0.09% |

|

|

TYPICAL PHYSICAL PROPERTIES |

|||

|

Hardness: |

Mohs:9.5 |

||

|

Specific Gravity: |

3.2g/cm3 |

||

|

Bulk density(LPD): |

1.2-1.6 g/cm3 |

||

|

Color: |

Green |

||

|

Particle shape: |

Hexagonal |

||

|

Melting Point: |

Dissociated at about 2600 ℃ |

||

|

Maximum service temperature: |

1900℃ |

||

|

Friability |

Friable |

||

Contact:

Ms. Chen

Moible/Whatsapp : 0086 13526538098