| Model: | GapGun Pro2/T60 |

|---|---|

| Brand: | - |

| Origin: | Made In United Kingdom |

| Category: | Electronics & Electricity / Electronic Instrument / Analysis Instrument |

| Label: | THIRD DIMENSION , GapGun Pro2 , T60V |

| Price: |

-

|

| Min. Order: | - |

| Last Online:26 Feb, 2025 |

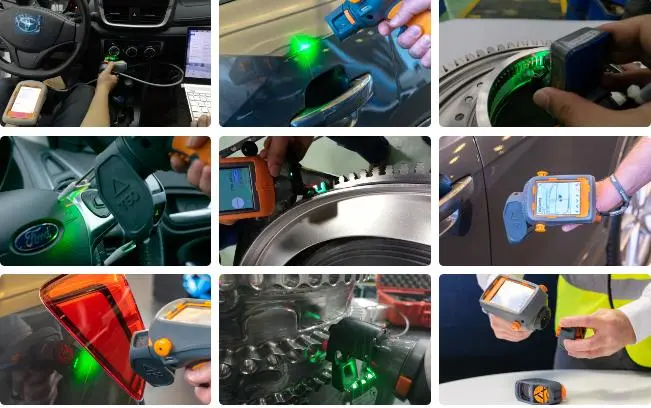

The sixth generation laser size gun GapGun Pro2/T60V

After more than 20 years of continuous research and development, GapGun has been one of the world's three major aerospace safety standards since the beginning. It has been rapidly developed and used in dimensional measurement in various industries, replacing the shortcomings of traditional tools and targeting parts that are difficult to detect and image using traditional coordinates and three-dimensional scanning: Whether it is the grinding and joining of aircraft engine blades, the assembly dimensions of high-end headphones and speakers, the clearance gap of automobile sheet metal, the precise shape of the internal bearings, the sharp edge rounding of mobile phones and computers, aircraft assembly and maintenance inspection, or the assembly and control of nuclear fusion reactor tiles , you will find GapGun’s success stories.

Real-life ergonomic design, tested by six generations of users, the latest sixth-generation handheld laser measuring instrument GapGun.The handle design adopts ergonomic principles, so you won't feel tired when you hold it for a long time.3.8-inch high-pixel full-color LCD display, resistive screen design, easy to operate even with gloves.Built-in two-channel speaker and vibrator, pre-input tolerance value, qualified and out-of-tolerance have different sound and vibration feedback.Passed and out of tolerance have different sound and vibration feedback.The first handheld purple laser probe, whose performance exceeds that of red/blue/green laser imaging. It uses a higher-end purple laser sensor with high energy and short wavelength. The frequency of the purple laser is 30% higher than that of the blue laser. The camera uses a more sensitive CMOS sensor to achieve Direct measurement of transparent and translucent parts.At the same time, the imaging quality and measurement accuracy are further improved for metal surfaces, plastic surfaces, fabric surfaces, color difference surfaces, and highly reflective surfaces.Powerful algorithms remove hardware errors, and single-line scanning is not interfered by any contour shape. GapGun adopts the market's mainstream laser measurement design and uses a single laser line measurement to accurately locate the measured position without being interfered by gradients and irregular contours around the measured position; market The mainstream single laser line design combined with the powerful algorithm support of SPC3d independently developed by Third Dimension Company can achieve fast and accurate measurement in 1 second.Dynamic reading, real-time analysis of 8 contour features. Supported by the algorithm independently developed by Third Dimension Company, GapGun can meet dynamic measurement and display measurement position values in real time. It is widely used in trend changes of assembly parts and installation of precision components.GapGun can simultaneously obtain multiple contour features such as gaps, steps, radius, angles, LLL, and LRL.The sixth-generation handheld laser measuring instrument has an extension range of up to 1 meter and a 360° non-dead angle measurement direction. It provides an optional extension cord with a diameter of 2.5mm and a length of 1mm. The 2.5mm thin extension cord can be bent at any angle to meet the measurement requirements in narrow locations.By measuring the extension cord, the burden of holding the equipment can be greatly reduced and the operating efficiency of the personnel can be improved.The length of the laser line is adjustable and can be divided into two. While providing a large measurement range, the T60 probe retains the function of adjusting the long and short laser lines for multiple characteristic parts.According to the measured characteristics, combined with the software algorithm, the laser length can be freely selected, which facilitates the software setting of the personnel and achieves rapid measurement of feature dimensions.The artificial mechanical design of application picture sharing makes GapGun6 portable for long-term online work.The violet laser technology with the shortest wavelength on the market can effectively quantify the contours of various light-absorbing, reflective and translucent materials, special paints and resin fibers regardless of the size of the workpiece and the different precision requirements.The independently developed single-beam scalable laser reflection is not limited by the contour shape, and the measurement accuracy does not suffer from complex contour changes.With a penetration depth of up to 1 meter and the flexibility to measure in any direction, it covers various difficult areas that are difficult to access.

| Embed HTML Code: | |

|---|---|