| Model: | P708 |

|---|---|

| Brand: | POLYFORTE |

| Origin: | Made In China |

| Category: | Construction & Decoration / Floors & Flooring / Other Floors |

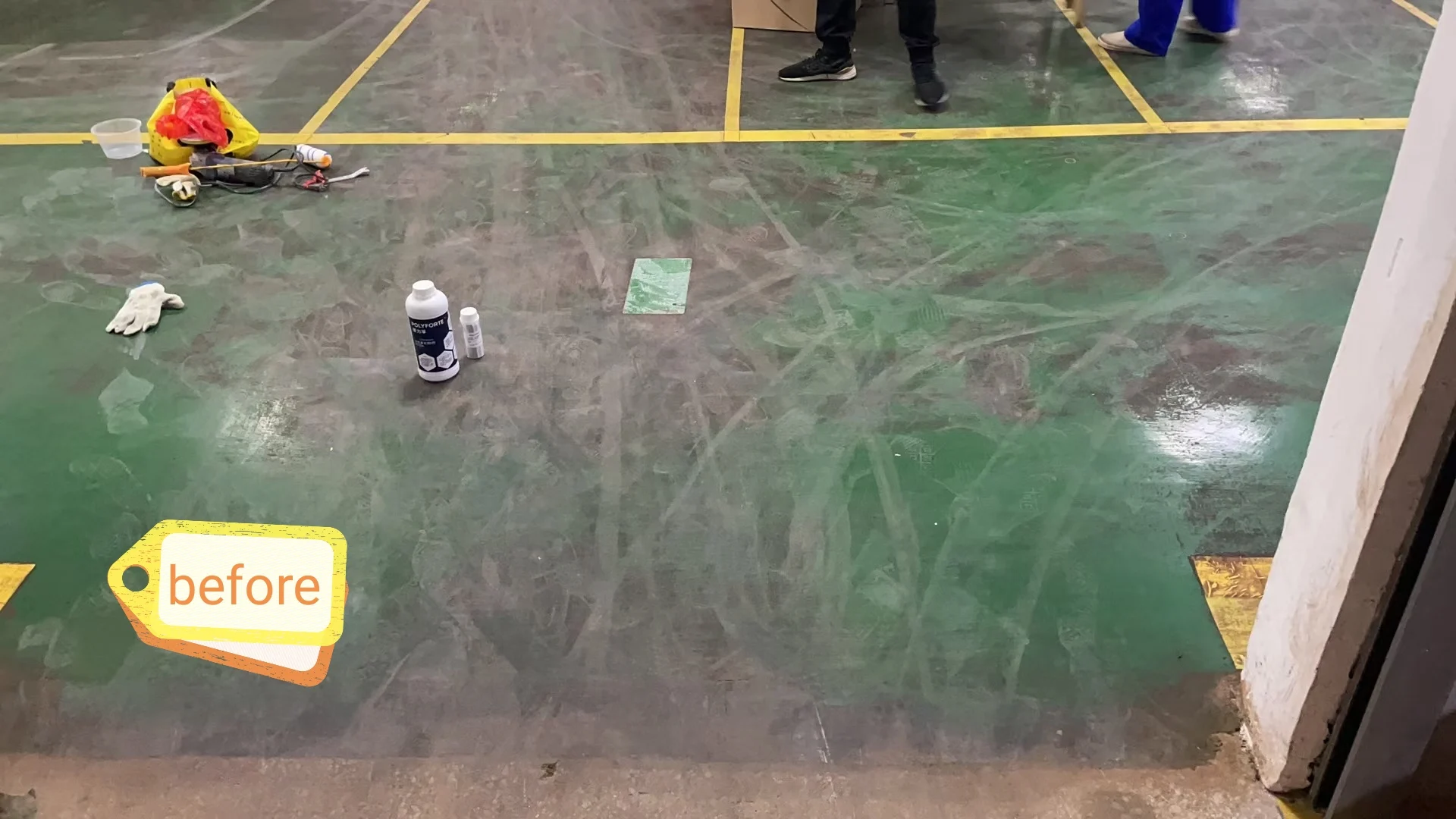

| Label: | floor coating , concrete coloring , refurbish floor |

| Price: |

¥75

/ kg

|

| Min. Order: | 16.5 kg |

| Last Online:11 Apr, 2022 |

Product Description

Polyforte water based dye concrete is a two-components product composed with A (dye agent )and B(curing agent) ,which can widely used on the concrete floor ,wall surface, metal surface etc.

Features :

Water-based ,environmentally and odorless.

Dyeing uniform , colorful ,not fade , resistant to yellowing , can be used indoors and outdoors.

Anti scratch , abrasion resistance , good corrosion resistance.

Easy to operate , can apply multi-layer

Quick dry and save time

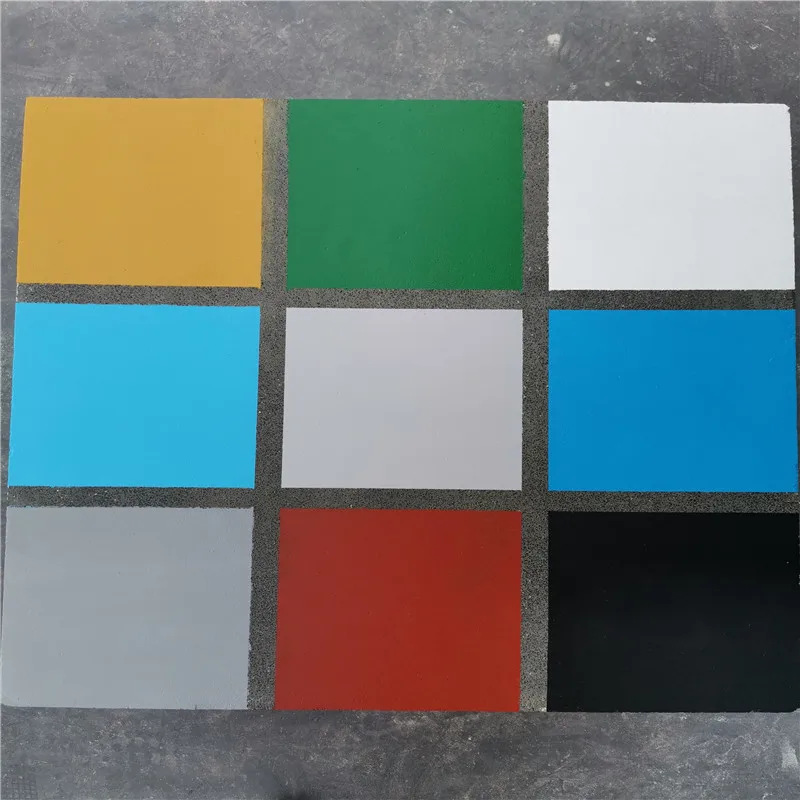

Colors:9colors

Medium grey , light blue,yellow, red, light grey , green, black , dark blue, white

Consumption for reference (kg/m2 )

Water-based primer : 0.1kg/m2

Water-based dye concrete :0.12kg/m2

Material Ratio:

Water-based dye concrete A:B=10:1

Water-based primer A:B: water=1:1.5:2

DIRECTIONS FOR USE

For the original ground should meet the below requirements

1. The intensity of the ground should reach to C30 at least , or should treat with the hardener agent to improve the intensity and grind to 150mesh then can put the water-based dye procedure .

2. Make sure the ground is level and no obvious scratches , if with holes or cracks ,should be repaired with cement repair mortar ,or water-based primer with special sand powder to repair smooth then dyeing .

3. Ground clean , without oil contaminated and sand.

4. No water on the ground.

Construction tools:

Grinding machine, water absorption machine. Metal girding disc , resin grinding disc, short hair rollers, mop and etc.

Treatment and process

1. Grinding the floor to evenly by the metal pads (50#-80#) . If the original floor is leveling can skip this procedure.

2. Apply the hardener to increase the intensity of the concrete, grinding to 150 mesh, wash the floor and leave to dry.

3. Apply the water based primer with the roller or flat knife ,and leave to dry (about 8hours )

4. After dry , apply the first layer dyeing , rolling while spreading

5. When the first layer dry then apply the second layer with the same method.

6. You can choose to seal by the sealer after the dyeing dry to reach more abrasion resistance properties.

Product applicable place

concrete floor ,epoxy floor, tile floor, emery floor wall surface, metal surface etc swift to refurbish.

Packaging & Shipping

Delivery times: 7-10 working days after received the deposit

Our Services

Accept OEM orders , products can be customized accoring to demand and flexible production .

Whether you are a small buyer or a big buyer ,we will provide you with the most professional solutions and quality service.

We supply new product training to our customers

Company Information

Polyforte Chemical Technology Co., Ltd is a private high-tech enterprise specializing in R&D ,production and sales of chemical products more than 15years ,which relying on institutions of higher education, Chinese Academy of Sciences and other scientific research institutions to develop high-tech chemical products, such as concrete seal hardener agent, coloring hardener, concrete repair materials, Ionic coloring agent, antistatic floor polish series, antistatic liquid series, static elimination agent series, and other products to fill the domestic gap and our products’ quality has reached the international advanced level. Our company insist that “to be the most sincere, to do our utmost ,to concentrate on the pursuit of perfection ”serve our customers.

factory & lab

Exhibition

Certifications