| Model: | HHP |

|---|---|

| Brand: | LYSZ |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Separation Equipment |

| Label: | - |

| Price: |

US $69800

/ pc

|

| Min. Order: | 1 pc |

| Last Online:06 Jun, 2022 |

Product Description

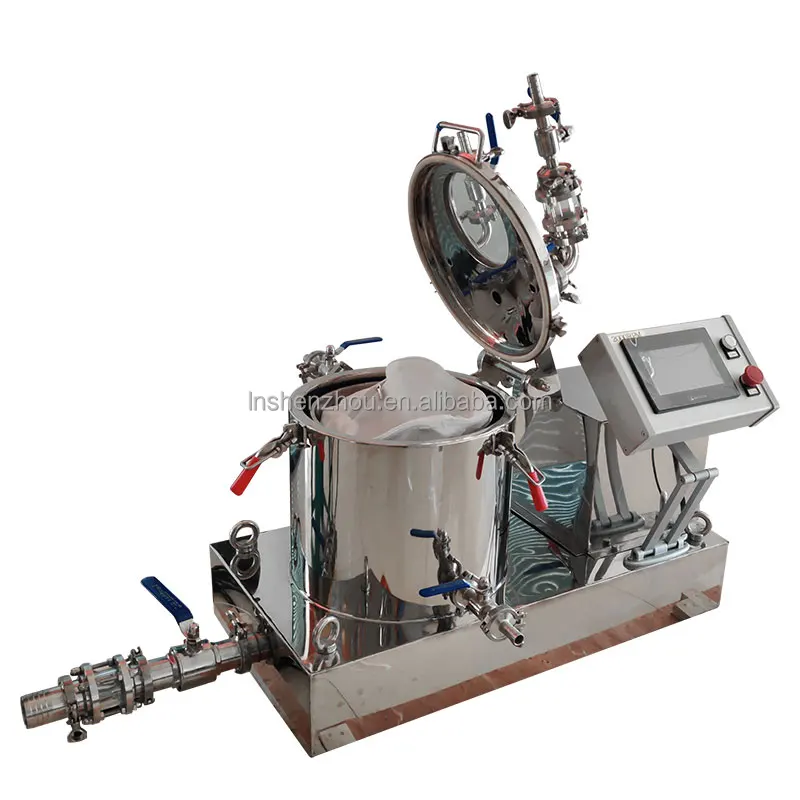

China manual sugar cane centrifuge machine for solid liquid separation

Industrial hemp oil extraction centrifuge

The centrifuge can be used to extract and filter centrifuges for and other plants. The series of centrifuges extract the active ingredients in plants through a built-in program, which is single-handed, easy to use and large in capacity.

The Centrifuge Machine is top discharging, hermetic closure type equipment. The material is fed into the drum through the feeding pipe on the hermetic closure casing; under the action of the centrifuge force field, the liquid-phase passes through the filter medium and the discharged out of the machine, while the solid-phase material is retained inside the drum and, after the machine is stopped, the material is discharged from the top. The centrifuge has such features as smooth running, easy & convenient operation as well as conducting feeding, washing and dehydrating under the state of hermetic closure, etc.

Product display

Specification

|

Model |

Drum diameter mm |

Drum height(mm) |

Volume(L) |

Revolving speed

|

Motor Power(KW) |

Size

(mm) |

Weight

(KG) |

|

SZPP-15 |

300 |

250 |

15 |

2000 |

1.1 |

950*500*480 |

210 |

|

SZPP-25 |

300 |

350 |

25 |

2000 |

1.5 |

950*500*580 |

220 |

|

SZPP-45 |

450 |

300 |

45 |

1500 |

2.2 |

1250*700*760 |

450 |

|

SZPP-60 |

450 |

400 |

60 |

1500 |

3 |

1250*700*860 |

470 |

|

SZPP-85 |

600 |

300 |

85 |

1250 |

3 |

1500*900*950 |

970 |

|

SZPP-110 |

600 |

400 |

110 |

1250 |

4 |

1500*900*1050 |

1000 |

|

SZPP-140 |

600 |

500 |

140 |

1250 |

5.5 |

1500*900*1150 |

1030 |

SZPP-15 Charge per batch around 5Kg(10 pound) Amount of ethanol each time around 30L(8 gallon)

SZPP-25 Charge per batch around 8Kg(18 pound) Amount of ethanol each time around 40L(11 gallon)

SZPP-45 Charge per batch around 14kg(30pound) Amount of ethanol each time around 85L(23 gallon)

SZPP-60 Charge per batch around 20kg(45pound) Amount of ethanol each time around 105L(28 gallon)

SZPP-85 Charge per batch around 25kg(55pound) Amount of ethanol each time around140L(37 gallon)

SZPP-110 Charge per batch around 35kg(75pound) Amount of ethanol each time around175L(46 gallon)

SZPP-140 Charge per batch around 45kg(100pound) Amount of ethanol each time around 210L(55 gallon)

Working principles of hemp oil extraction centrifuge

* Patented technology of double sealing of Teflon(PTFE) and FV rubber ensures the negative pressure level.

* Automatic switch valve makes continuous collection possible without affecting vacuum degree and without stopping distillation.

* Teflon discharge valve is corrosion resistant and contamination free.

* Water bath jacket protecting operator from scalding by hot liquid.

* Motorized water bath lifting for precise control.

* Quick clamp connections for easy and fast installation.

* PID temperature controller ensures accurate temperature control is maintained.

* Optional stainless steel evaporating flask carrier with silicone cushions is designed for safer and easier loading and

unloading of the flask. It can also be used as a flask stand.

Environmental, transportation, storage requirements

1 Working environment: temperature -50 ° C -50 ° C; air relative humidity is not more than 85%.

2 Transportation: Centrifuges must not be rolled and inverted during shipment, and must not be stacked to prevent rainwater intrusion.

3 Handling: The centrifuge must be hoisted according to the position of the center of gravity of the centrifuge during the

handling process. The machine is equipped with 4 lifting rings. When lifting, try to keep the level of the centrifuge. Do not roll and invert.

4 Storage: The centrifuge should be placed at a temperature of 0-40 ° C, the relative humidity of the air is not more than 85%, and there is no corrosive medium to avoid the place.

The centrifuge must be kept by a person before installation and use to ensure the integrity of the centrifuge. The technical

status and installation of the centrifuge should be confirmed by the manufacturer before operation.

Machine installation and adjustment

1 Installation Precautions

1.1 The machine must be kept in storage before and after installation. Pay attention to the moisture protection of the motor and pay attention to the protection of the electronic control system.

1.2 Safety must be taken during lifting to prevent the machine from being damaged by collision.

1.3 The centrifuge installation must be horizontal and the reference surface is the upper plane of the machine base (level ≤ 3mm).

1.4 There should be sufficient space between the equipment and other equipment installed adjacent to the centrifuge and the centrifuge to prevent the machine from colliding with it and causing damage or noise, and to facilitate inspection and maintenance of the machine.The space required for the use and maintenance of the centrifuge should be considered during the installation position of the centrifuge.There should be a pedestrian passage of not less than 1 meter around the centrifuge main unit. There must be more than 2 meters of assembly and disassembly maintenance space above the centrifuge main unit.

1.5 Because the centrifuge has slight vibration during high-speed operation, the pipe (feeding pipe, outlet pipe, washing pipe, exhaust pipe, cable pipe, etc.) connected to the centrifuge must be flexibly connected, and the connection must be reliable.

Sealed or insulated to ensure no leakage and safe use of electricity. The diameter of the external outlet pipe shall not be less than the diameter of the machine outlet pipe, and shall not have dead bends or blockages. The pipe arrangement shall be lower than the height of the outlet pipe outlet and have a certain height difference so that the liquid discharge is unblocked.

1.6 Select the appropriate filter cloth type to make the filter bag according to the characteristics of the separated materials. And ensure the filter bag and the drum body have a good fit according to the filter bag provided by the manufacturer.

1.7 The electrical wiring is connected by an electrician according to the electrical control schematic diagram of the PP series centrifuge to wait for the operation and adjustment of the centrifuge.

1.8 After the centrifuge is installed, turn on the motor power, adjust the tension of the motor’s V-belt, and prepare for the test run.

Warning

2.1 The cover must be covered and locked before the centrifuge for hemp oil extraction is running!

2.2 Do not open the cover when the machine is running!

2.3 It is strictly forbidden to use rigid connection among the feeding tube, the washing tube and the liquid discharging tube on the main machine of the centrifuge, so as not to affect the vibration damping system of the main machine itself and damage the machine.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.