| Model: | GR5 |

|---|---|

| Brand: | Baoji First Titanium Industry(Group) Co.Ltd |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Non-ferrous Metal Alloy |

| Label: | High strength bar , corrosion resistance , GR5 titanium bar |

| Price: |

US $22.5

/ kilo

|

| Min. Order: | 50 kilo |

| Last Online:28 Dec, 2021 |

Baoji FIRST Titanium industry (Group) Co.LTD is a high-tech enterprise focusing on research and development of Titanium Bar. We produce our products and cooperate closely and steadily with well-known research institutions, universities, national laboratories and innovative corporate giants in nanomaterials research and development. We are committed to provide the highest quality products with the most reasonable price for our customers who are doing nanotech research and have formed a complete cycle of researching, manufacturing, marketing and after-sale servicing. Our products have been sold to many countries around the world.

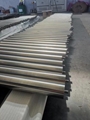

Titanium alloy rod corrosion resistance GR5 titanium rod high strength

Titanium metal has great passivation property, in many cases, when contacting with dissimilar metal, it does not accelerate the corrosion, but may accelerate the corrosion of dissimilar metal. For example, in low concentration of non-oxidizing acid, if Pb, Sn, Cu or Monel alloy contact with titanium to form galvanic pair, the corrosion of these materials is accelerated, and titanium is not affected. Corrosion resistance, high strength, acid and alkali resistance, light weight, etc.

Titanium alloys are alloys based on titanium with other elements added. Titanium has two kinds of homogeneity crystal: titanium isomer, melting point is 1668℃, below 882℃ is a dense hexagonal lattice structure, called α -titanium; Above 882℃, the cubic structure is called β -titanium. Titanium alloys with different structures can be obtained by adding appropriate alloying elements and changing phase transition temperature and component content.

Physical phenomenon of titanium processing: the cutting force of titanium alloy processing is only slightly higher than that of steel with the same hardness, but the physical phenomenon of titanium alloy processing is much more complex than that of steel, so that titanium alloy processing is faced with great difficulties. Most titanium alloys have very low thermal conductivities, only 1/7 of steel and 1/16 of aluminum. Therefore, in the process of cutting of titanium alloy heat will not quickly passed to the artifact or taken away by chip, and agglomeration in cutting area, the temperature can be as high as 1 000 ℃ above, make the cutter blade quickly wear, cracks, and generate the devolop tumor, rapid wear of the blade, and make the cutting area produces more heat and further shrinkage of life. The high temperature in the cutting process destroys the surface integrity of titanium alloy parts, resulting in the decrease of geometric accuracy and the phenomenon of work hardening which reduces the fatigue strength seriously.

Please indicate the material brand number, technical parameters, use environment, specifications and so on when purchasing goods from our store to prevent unnecessary losses to customers.

Baoji Firstti Titanium industry (Group) Co., LTD., titanium rod specifications produced are included:

The United States label number: GR1, GR2, GR3, GR5, GR7, GR12 Titanium rod manufacturing process: hot forging - hot rolling - car light (polished) titanium rod implementation standard: American standard: ASTM B348, ASTMF136, ASTM F67, AMS4928, reference standard 228 Metal Tensile test Method 3620.1 Titanium and titanium alloy and chemical composition Titanium and titanium alloy processed products chemical composition and allowable deviation 4698 Titanium sponge, titanium and titanium alloy chemical analysis method II, Technical Requirements 1. The chemical composition of titanium and titanium alloy bars shall comply with the provisions of GB/T3620.1. In case of repeated inspection, the allowable deviation of chemical composition shall comply with the provisions of GB/T 3620.2. 2. The diameter or side length of hot-working bar and its allowable deviation shall conform to the provisions in Table 1. 3. After hot processing, the allowable deviation of cold-drawn bar diameter shall conform to the provisions of Table 2. 4. After hot working, the roundness of the turning (grinding) polished bar shall not exceed half of its dimensional tolerance. 5. The variable length of the processed bar is 300-6000mm, and the variable length of the annealed bar is 300-2000mm. The fixed length or multiple length should be within the range of the variable length. The allowable deviation of fixed length is +20mm; The length of double length shall also be included in the cutting quantity of the bar, and each opening quantity shall be 5mm. The fixed length or double length shall be indicated in the contract.