| Model: | LTY-01 |

|---|---|

| Brand: | Link Testing |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | Leak Tester , Leakage , Sealing performance |

| Price: |

US $1000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:07 May, 2022 |

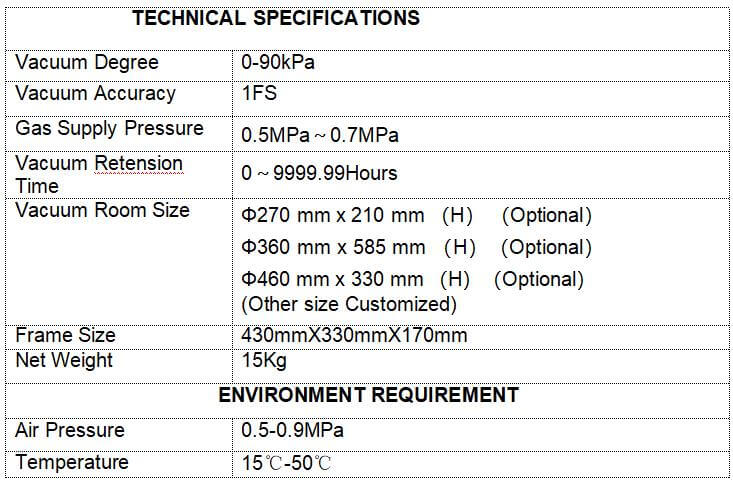

Vacuum Leak Tester LTY-01 is designed for leak test for food, drugs, cosmetics, industrial products such as flexible packaging, bottles and other packaging materials. LTY-01 adopt negative pressure test mode, automatic chronograph automatic replenishment vacuum packaging, is high-precision automatic leak testing machine. Sealing process and sealing performance can be effectively tested and evaluated. packaging leak tester

TECHNICAL FEATURE

★Color touch screen control, make the operation more convenient, more intuitive results

★The vacuum chamber is made of high transparent organic glass

★Simple and convenient detection and calibration Leak Tester

★Specimens could be tested in the preset vacuum condition by automatic compensation of constant pressure

★Imported brand vacuum components, stable performance, durable

★One key operation, automatic end test, automatic Blowback unloading

★User level management to ensure data integrity and standardization

★Store multiple sets of test data, easy query

★ISP online upgrade function, can provide personalized service

★High speed processing chip, greatly improve the operating speed

★The vacuum pressure and pressure holding time can be set to simulate and evaluate the sealing of the packing under different vacuum conditions

★The pressure and pressure holding time can be set freely in each vacuum stage

English Operation Interface

English Operation Interface

TEST PRINCIPLE

Vacuum Leak tester using the negative pressure method principle, vacuum the vacuum chamber to make the immersed water sample have internal and external pressure difference. Observe gas escape situation to determine the sealing performance of the sample. Or vacuum the vacuum chamber to make the immersed water sample have internal and external pressure difference. Observation sample expansion and shape of the samples after the release of vacuum recovery and liquid infiltration condition to determine the sealing performance of the sample. Leak Tester

Standards: GB/T 15171, ASTM D3078