| Model: | BFA |

|---|---|

| Brand: | XINLI |

| Origin: | Made In China |

| Category: | Industrial Supplies / Tools / Abrasives |

| Label: | brown fused alumina , BFA powder , Brown Corundum Powde |

| Price: |

US $1000

/ TON

|

| Min. Order: | 1 TON |

| Payment Terms: | TT/LC/DP/DA |

| Last Online:02 Jan, 2023 |

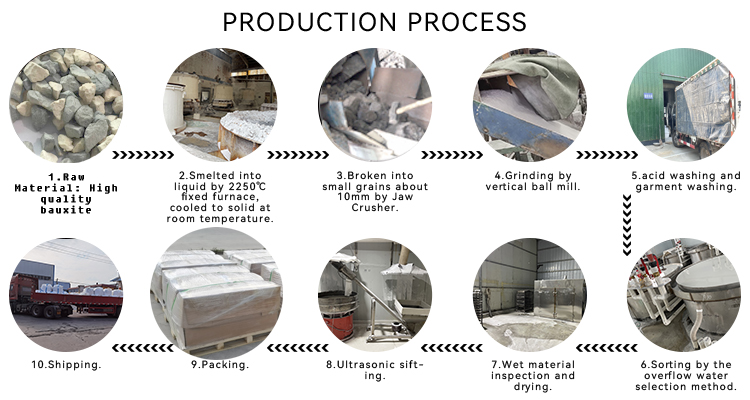

Brown corundum micro powder takes the high-quality bauxite ore in deep underground as the raw material, produced by 24 hours uninterrupted high-current high-temperature smelting, cooling and crystallization. The conversion rate of the α-Al2O3 is over 99%, can be produced according to JIS, European Standard, National Standard, or according to customers’ special requirements.

Advantages Of Brown Corundum Powder:

1. Large crystal, high strength, good toughness, dense texture, high bulk density.

2. Stable performance between batches.

3. The higher grinding efficiency and polishing brightness, the grinding efficiency is much higher than the soft abrasives such as silica.

4. Good particle appearance, high surface finish of the polished object.

Product Parameter

|

Grains Specifications And Composition |

||||

|

JIS |

240#,280#,320#,360#,400#,500#,600#,700#,800#,1000#,1200#,1500#,2000#,2500#,3000#,3500#,4000#,6000#,8000# |

|||

|

European standard |

F240,F280,F320,F360,F400,F500,F600,F800,F1000,F1200,F1500 |

|||

|

National standard |

W63,W50,W40,W28,W20,W14,W10,W7,W5,W3.5 |

|||

|

Chemical Composition |

||||

|

Grains |

Chemical composition(%) |

|||

|

Al2O3 |

SiO2 |

Fe2O3 |

TiO2 |

|

|

240#--1000# |

≥94.5 |

≤1.5 |

≤0.15 |

≤2.5 |

|

1500#-4000# |

≥94.0 |

≤1.5 |

≤0.20 |

≤2.5 |

|

6000#-8000# |

≥92.0 |

≤2.0 |

≤0.5 |

≤3.0 |

Product Details

Zhengzhou Xinli Wear-Resistant uses the latest wet ball mill to crush to ensure the plump particles and sharp edges and corners. Also uses the wet cooling method, the surface color is pure brown-red, then uses magnetic separation, pickling, and moisture to ensure the uniform particle size distribution. Finally uses the microscope and laser particle size analyzer to ensure the stability between batches.

Application

White Aluminum Oxide Powder Applications

1. Sandblasting, polishing and grinding of metal and glass. 2. Filling of the paint coating and ceramic glaze. 3. Production of oil stone, grinding stone, grinding wheel, sandpaper and emery cloth. 4. Production of ceramic filter membranes, ceramic tubes, and ceramic plates. 5. Production of polishing liquid, solid wax and liquid wax. 6. For wear-resistant floor. 7. Advanced grinding and polishing of piezoelectric crystals, semiconductors, stainless steel, aluminum and other metals and non-metals.