| Model: | DX1000 series |

|---|---|

| Brand: | hyportable |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

| Label: | milling machine |

| Price: |

¥6000

/ pc

|

| Min. Order: | 1 pc |

| Last Online:07 Jun, 2023 |

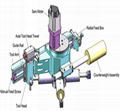

DX1000 portable single arm milling machine introduction

DX1000 portable single arm milling machine adopts multi-function, lightweight, combined structure design, mainly used in the field working conditions for plane, groove and keyway processing, common in steel mill arch, heat exchanger, hydrogenation reactor, pump and motor base, hatch cover and other shipbuilding industry, iron and steel industry and more applications.

DX1000 portable single arm milling machine Features:

1) X and Y adopt precision pretightening ball screw with strong rigidity and high precision. The feed drive adopts the large inertia speed regulating AC servo motor connected with the ball screw. The coupling adopts the imported non-clearance coupling to ensure the non-clearance transmission, which greatly improves the dynamic rigidity of the transmission system.

2) X and Y are respectively equipped with imported high-precision linear guide rail, X and Y axis driven by motor ball screw to achieve drive feed, cutting stability and good vibration resistance, high sensitivity to move, can improve the performance characteristics of machine tools, improve the accuracy and precision stability of machine tools and the service life of machine tools.

3) Adopt imported centralized timing and quantitative automatic oil supply lubrication system to minimize the error caused by hot deformation of high-speed operation.

4) The base is made of 45# steel, which is manufactured and processed by special heat treatment and processing process, with low cost, good stiffness and not easy to deformation. The lead screw is made of high chromium alloy to ensure wear resistance and stiffness, and the guide rail is made of excellent alloy steel.

DX1000 portable single arm milling machine parameters

Main motor power: 3KW servo motor

Feed mode: X (main track), Y (transverse track) automatic feed, Z (vertical direction) automatic feed

Feed stroke:

X stroke: 1000mm

Y stroke: 300mm

Z-direction stroke: 150mm

Machining flatness: 0.1mm

Roughness: 3.2

Fixing method: Bolt fixing

Cutter head: 160mm

2-10 meters can be customized