Four spindle round bar deep hole drilling machine

Product Description

The shaft type deep hole drill is a specialized deep hole drilling machine designed for the processing of central deep holes in shaft parts, aiming to provide customers with efficient, high-precision, and high smoothness solutions for deep hole processing of shaft parts.

The main characteristics of shaft type deep hole drills:

1. A deep hole machining machine designed specifically for machining central holes in bar materials.

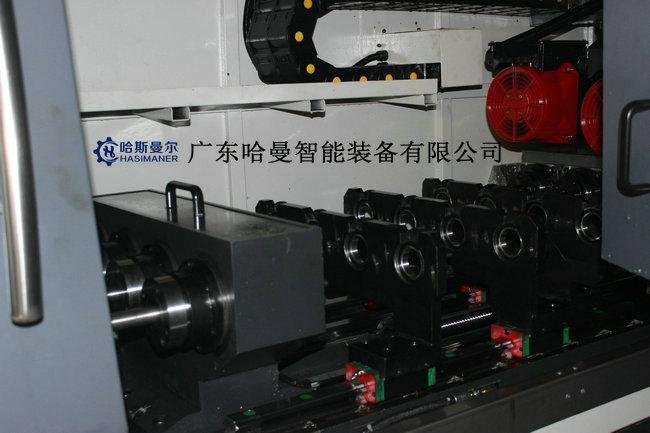

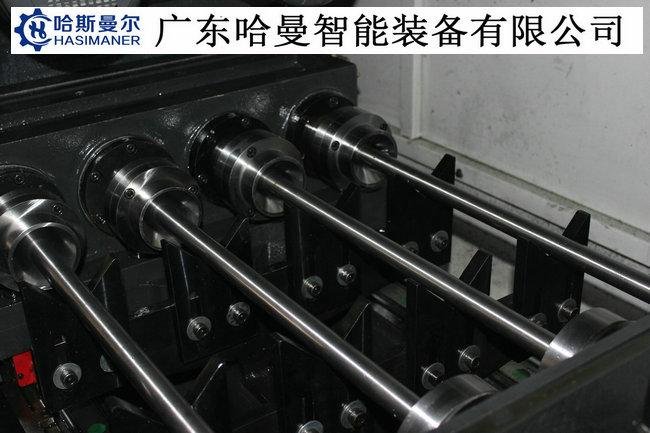

2. Simultaneous processing with dual or four spindles greatly improves work efficiency.

3. Conical hole guidance and high-pressure oil cooling provide guarantee for high precision and high smoothness.

4. Siemens or Taiwan's new generation CNC systems can be selected according to customer requirements.

5. The equipment can be equipped with a robotic arm for automatic loading and unloading, with a high degree of automation.

Application field of shaft type deep hole drilling machine tools: machining of central and deep holes in shaft parts

Processing materials for shaft deep hole drilling: low-carbon steel, high carbon steel, mold steel, titanium alloy, non-ferrous metals, etc

Axis Series CNC Axis Deep Hole Drilling Machine Tool Specification Table

Technical parameters of Axis series deep hole drilling machine tools

Serial Number Project Axis-300 Axis-500 Axis-800 Axis-1000

1. Bore diameter range Gun drill: φ 3~ φ 20mm BTA: φ 20- φ eighty

2. Maximum depth of drilling hole 300mm 500mm 800mm 1000mm

3. Workpiece clamping method: cone chuck

The range of the workpiece held by the 4 chuck is based on the actual processing requirements of the customer

5 Machine tool weight 2.5 tons

6 Single axis stroke 350mm 550mm 850mm 1050

7 Spindle center height according to customer requirements

8 spindle speed range (stepless) 0-8000r/min (maximum 7000r/min)

9. Tool feed speed range (stepless) 0-200mm/min

10 Fast moving speed 5000mm/min

11 Cutting oil tank capacity 200L

12 spindle axes (optional) 1 axis 2 axis 4 axis

13 coordinate movement Z (drilling direction) 1 coordinate movement

14 machining accuracy, aperture accuracy H8~H11, surface roughness Ra ≤ 3.2 of the hole μ M

Deviation of hole axis from reference 0.3/1000mm

15 movement modes: spindle gun drill movement, workpiece rotation

16. The lubrication method adopts the central lubrication method

17. Intelligent monitoring of machining process, including cutting oil pressure, machining progress, spindle speed, feed speed, etc

18. The spindle connection adopts an imported rotary joint

Guangdong Harman Intelligent Equipment Co., Ltd

Guangdong Harman Intelligent Equipment Co., Ltd

Contact person: Mr. Zhang

Contact: Mr. Zhang

Company phone: 0769-22282468

Company phone: 086-0769-22282468

Contact phone number: 15361639518 (same WeChat account)

Tel: 086-15361639518 (WeChat

| Lead Time: | xiaoshou@shenkongzuan.com.cn |

| SKU: | 1000台 |

| |

Product Image

Img 1

Img 2

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,