| Model: | - |

|---|---|

| Brand: | GYPEX |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Heat Exchange & Air Conditioners |

| Label: | - |

| Price: |

-

|

| Min. Order: | - |

| Last Online:09 Apr, 2024 |

Note:

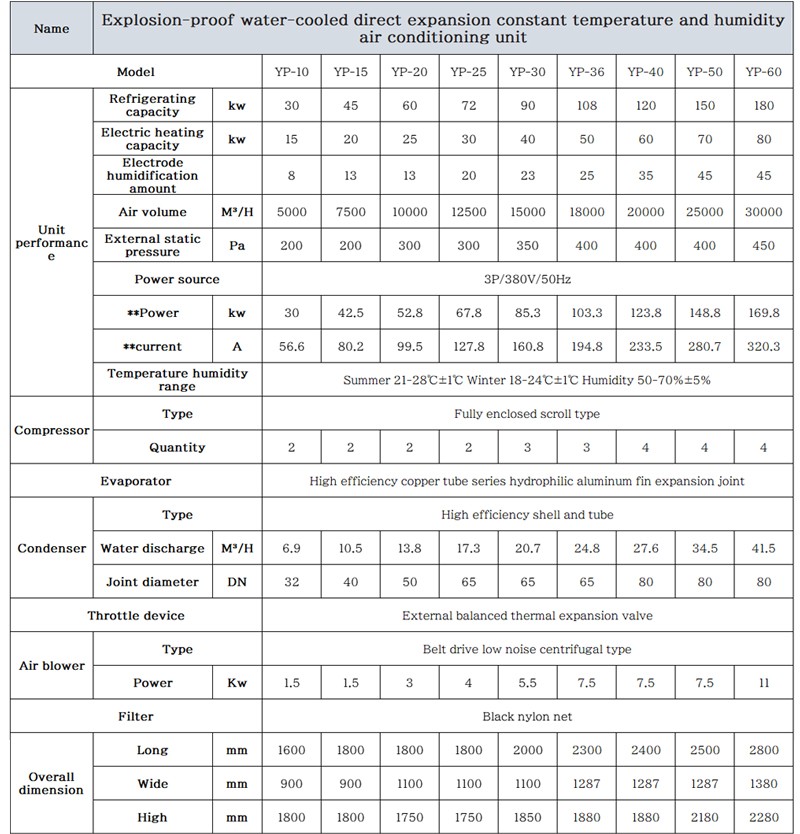

1. Cooling capacity measurement working condition: indoor dry bulb 27°C wet bulb 19°C, cooling water inlet and outlet temperature: 30°C/35°C

2. Operating range: intake air temperature 18-32°C, cooling water temperature: 20-34°C

3.** power does not include cooling pump, cooling tower motor power

Product features:

1, the smart and simple design makes maintenance and maintenance very convenient, all the parts of the unit can be directly inspected and repaired

from the front, and without stopping.

2. The evaporation coil adopts high purity seamless internal thread copper tube and aluminum spoiler fin through mechanical expansion tube to make

copper tube and aluminum sheet closely bonded to play the heat transfer effect.

3. The hydrophilic treatment of the aluminum sheet can effectively reduce the thickness of the condensate film during refrigeration operation, reduce

the thermal resistance of the water film, and improve the coil heat transfer efficiency.

5, the fan adopts the front curved multi-wing centrifugal double suction impeller, the impeller is tested by dynamic balance, no noise vibration

phenomenon in long-term operation, to ensure the high air supply effect; The pulley drive can flexibly change the unit air volume, external residual

pressure and other parameters in order to match with the actual project; The fan comes with a motor adjustment board, which can easily adjust the

tightness of the belt.

6, the water cooling unit uses efficient tube or shell and tube condenser, the heat transfer coefficient is large, the unit energy efficiency ratio is high.

7, the skeleton structure, higher rigidity of the internal parts, reduce the vibration noise of the unit, each shell board is pasted with sufficient thickness

of insulation, noise reduction material, and can be easily removed.

8, thermal expansion valve design can accurately control the flow of refrigerant injected into the evaporator, but also protect the compressor motor

from liquid refrigerant damage. Separate valves, that is, separate body and spool, can be supplied with an integral valve (fixed orifice) or replaceable spool.