| Model: | Welding Wire |

|---|---|

| Brand: | Hard-plate |

| Origin: | - |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

| Label: | Gas Shielded Wire , Welding Wear Wire , Flux Cored Welding W |

| Price: |

US $90

/ pc

|

| Min. Order: | 1 pc |

| Last Online:10 Oct, 2024 |

Gas Shielded Flux Cored Welding Wire

Gas-shielded flux-cored welding wire is suitable for high-temperature, high-precision welding environments with high requirements for weld quality, such as the chemical and electric power industries. It is necessary to ensure that there is no interference from impurities such as oxygen and water vapor during the welding process.

Overview:

Gas shielded flux-cored welding wire is a welding wire that achieves stable and protected weld quality through external gas protection.

Its characteristic is that it needs to be equipped with gas protection equipment during the welding process, such as argon arc welding machine, protective cover, etc.

Due to gas protection, gas shielded flux-cored welding wire can effectively remove harmful gases and impurities in the air during the welding process, thereby ensuring the quality of the weld.

Surface Finish:

Applications:

| Model | Wire diameter(mm) | Alloy Chemical Composition(%) | Performance And Use | |||||||||

| C | Cr | Si | Mn | B | Mo | Nb | W | V | Ni | |||

| HP220Q | 1.2-1.6 | 4.0-5.0 | 19.5-20.5 | 0.7-1.2 | 0.7-1.2 | 0.4-0.7 | Open arc surfacing welding wear-resistant plate welding wire,Suitable for medium impact wear condition | |||||

| HP224Q | 1.2-1.6 | 4.0-5.3 | 23-25 | 0.7-1.2 | 0.7-1.2 | 0.4-0.7 | ||||||

| HP228Q | 1.2-1.6 | 4.2-5.5 | 27-29 | 0.5-1.2 | 0.7-1.2 | 0.4-0.7 | ||||||

| HP300Q | 1.2-1.6 | 4.2-5.5 | 24-27 | 0.5-1.2 | 0.7-1.2 | 0.3-0.7 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | Resistant to high temperature condition of 600 degrees wear-plate surfacing welding wire | |

| HP308Q | 1.2-1.6 | 4.2-5.5 | 21-25 | 0.5-1.2 | 0.7-1.2 | 0.3-0.7 | 2.3-3.5 | 2.5-3.5 | 0.8-1.5 | 0.8-1.5 | Resistant to high temperature condition of 800 degrees wear-plate surfacing welding wire | |

| HP6300Q | 1.2-1.6 | 4.2-5.5 | 24-27 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.5-1.5 | 0.2-0.4 | Single roller cursher teeth,Grizzly bar,Distributor chute ,etc.High temperature and wear resistant parts production and repair of surfacing welding wire |

| HP6308Q | 1.2-1.6 | 4.2-5.5 | 21-25 | 0.5-1.5 | 0.7-1.5 | 0.3-0.7 | 2.5-3.5 |

2.5-3.5 |

0.8-1.5 | 0.8-1.5 | 0.2-0.4 | |

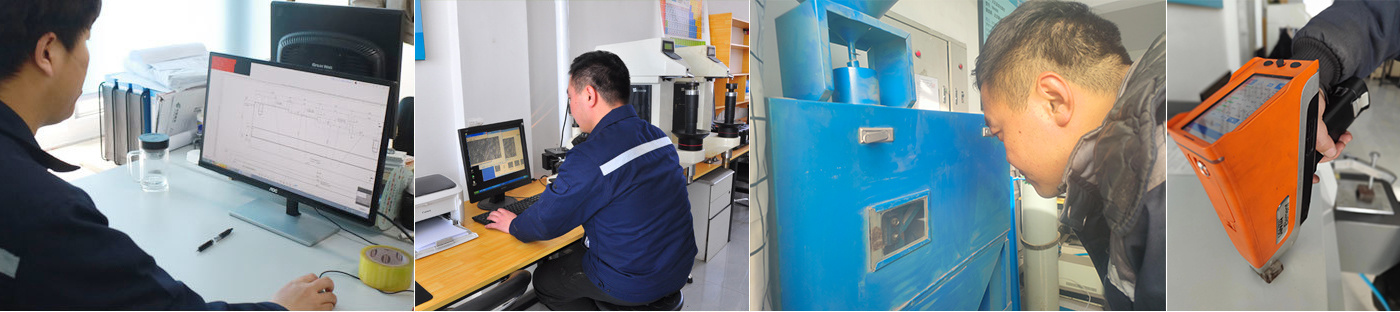

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University

R & D ABILITY

♦Liaoning high-tech enterprise,wear-resistant overlay welding demostration center of MIIT

♦More than 50 national patents including invention patents

♦Well-equipped laboratory with high-end metallographic analysis equipment, spark- optical emission spectrometer.Carbon sulfur analyzer,spectro-photometer,grain-abrasion testing machine,rockwel hardness apparatus,impacttesting machine

♦Participate in setting wear-resistant pipe standard for DL/T power industry

♦Member of China Welding Association

♦Industry-university-research cooperation enterprise of Liaoning petrochemical University