| Model: | SJ5500 Series |

|---|---|

| Brand: | CHOTEST |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Electronic Instrument / Laboratory Instrument |

| Label: | utm , thread measurement |

| Price: |

US $1

/ pc

|

| Min. Order: | 1 pc |

| Last Online:21 Oct, 2024 |

Product Description

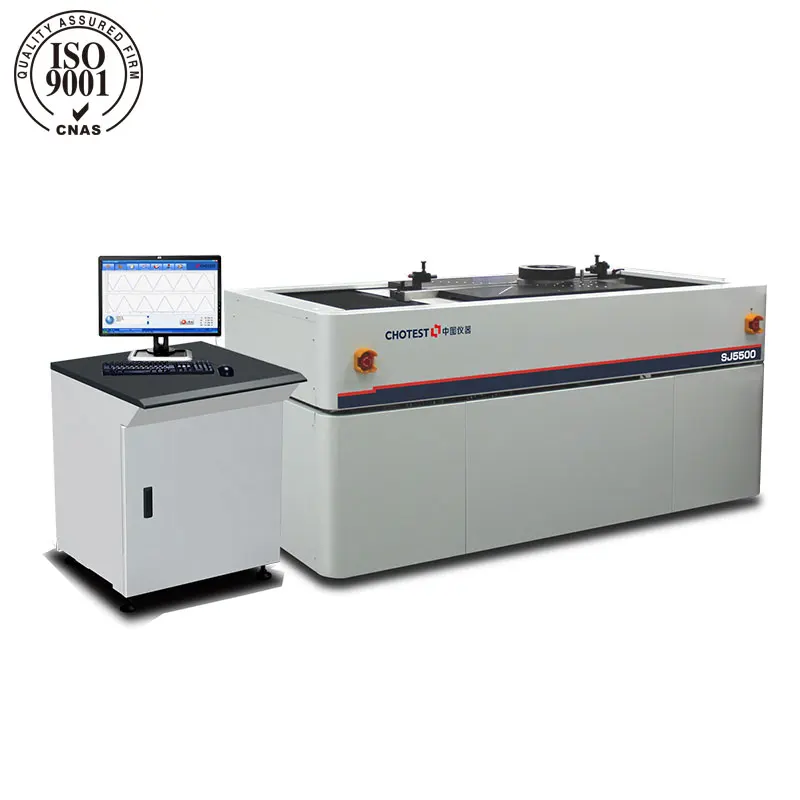

Universal Thread Measuring Machine - SJ5500 Series

Universal Thread Measuring Machine(UTM) SJ5500 achieves full-automated and precision measurement of comprehensive thread parameters by using Heidenhain precision linear encoder system, precision air bearing drive system, imported servo motor control system, high performance industrial computer control system and large capacity memory technology. After driving the measuring probe to contact with workpiece by precision air bearing system, the software records the horizontal and vertical coordinates in measuring process by applying Heidenhain precision linear encoder system, then, on the basis of synthesizing the two-dimensional measuring values , the software calculates and obtains a variety of thread parameters according to relevant definitions.

SJ5500 is a full-automated measuring machine. The operator only needs to install the thread, select matching standard and input relevant sizes & measuring range & other parameters in software, then the system measures automatically after click the "start" button. The software displays real-time tooth profile curve of thread and calculate the major diameter, pitch diameter, minor diameter, thread pitch, thread angle, other thread parameters automatically. Finally the system qualifies a variety of thread parameters according to built-in thread standards, and test result is generated automatically. The whole process is completed in 2 min.

Advantages

Parameters

| Model No. | SJ5500-200 | SJ5500-300 | SJ5500-400 | SJ5500-500 | SJ5500-600 |

| External measuring range | (1.0-250)mm | (1.0-350)mm | (1.0-450)mm | (1.0-550)mm | (1.0-620)mm |

| Internal measuring range | (2.5-250)mm | (2.5-350)mm | (2.5-450)mm | (2.5-550)mm | (2.5-620)mm |

| Max scanning length | 250mm | ||||

| Min pitch | 0.1mm | ||||

| Weight | 2000kg | ||||

| Size | 2000×900×910mm | ||||

| Measuring Uncertainty: | |||||

| Cylindrical or Taper ring gauge(Mimor diameter >2.5mm, half of thread angle ≥27°) | |||||

| Minor diameter | 3.0 + L/200μm | ||||

| Pitch diameter | 3.0 + L/200μm | ||||

| Pitch | 0.8 + L/200μm | ||||

| Cylindrical or Taper plug gauge (Major diameter >1.0mm, half of thread angle ≥27°) | |||||

| Major diameter | 2.9 + L/200μm | ||||

| Pitch diameter | 2.9 + L/200μm | ||||

| Pitch | 0.8 + L/200μm | ||||

| Plain ring or plug gauge | 2.0 + L/200μm | ||||

| Other measurement | 2.0 + L/200μm | ||||

| Contour measurement | |||||

| Outside measuring range | (0-250)mm | (0-350)mm | (0-450)mm | (0-550)mm | (0-620)mm |

| Inside measuring range | (2.5-250)mm | (2.5-350)mm | (2.5-450)mm | (2.5-550)mm | (2.5-620)mm |

| Resolution of X-axis and Y-axis | 0.01μm | ||||

| Accuracy of X-axis | ±(1.5+L/100)μm | ||||

| Accuracy of Z-axis | ±(1.5+L/100)μm | ||||

| Max gradient | 75°(T-shaped measuring probe) | ||||

| Measuring force | (40-150)mN adjustable | ||||

| Measuring speed | (0.01~2)mm/s | ||||

Functions

1. Full-automatic measurement for comprehensive parameters of cylindrical thread plug gauges, cylindrical thread ring gauges, taper thread plug gauges, taper thread ring gauges, plain ring gauges, plain plug gauges and other gauges with internal & external dimensions, including virtual pitch diameter , single pitch diameter, basic pitch diameter, major diameter, minor diameter, thread pitch, thread angle, half of thread angle, flank straightness, lead angle, taper, etc.

2. Can measure trapezoidal thread gauges, buttress thread gauges, sawtooth thread gauges and other large-slope thread gauges.

3. Can measure comprehensive parameters of single thread and multiple thread.

4. Measure various thread gauges according to GB, ISO, BS, ANSI, DIN, JIS, API standards. With comprehensive and professional thread standards in database, it meets requirements of most customers.

5. Automatically generate test report according to selected standard.

6. After once measurement, the software can records various parameters of thread and display data of any position, in addition it generates the thread curve, relevant parameters and analysis chart automatically.

7. Measuring probe and workholder are identified automatically, which avoids collision of measuring probe caused by misoperation.

8. One-sided or two-sided measurement and analysis for gauges.

9. Controller for measuring pin positioning: with an easy-to-use buttons control box, the operation is more flexible.

10. User-friendly English software system and simple & convenient operation.

11. Test results are saved automatically with name of measuring series number + size of measuring gauge + type of measuring gauge, which can be recognized easily. With centralized database management for measuring records, the user can query and manage the measuring records according to object type, testing institution, manufacturing number, inspector, submitted institution, equipment number, inspection date, effective date, etc.

12. Can print multiple selected test records or test certificates from database at once time.

13. Can export test data to Word, Excel, AutoCAD (optional) files.

14. Data backup and restore.

15. Output reports in a variety of formats in Word or PDF, particularly the format can be customized.

16. Support user-defined standards.

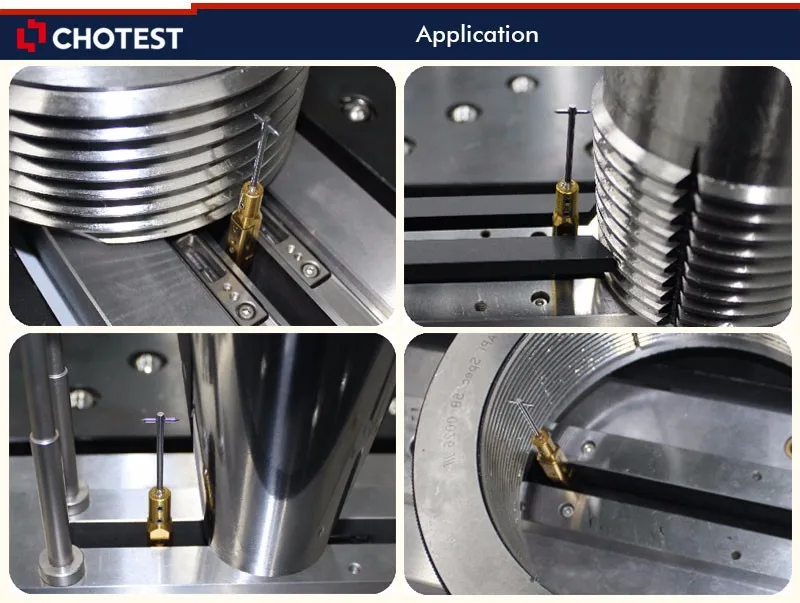

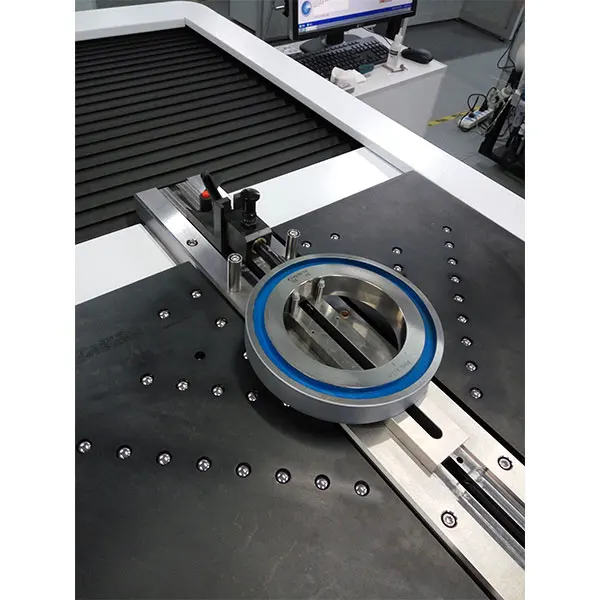

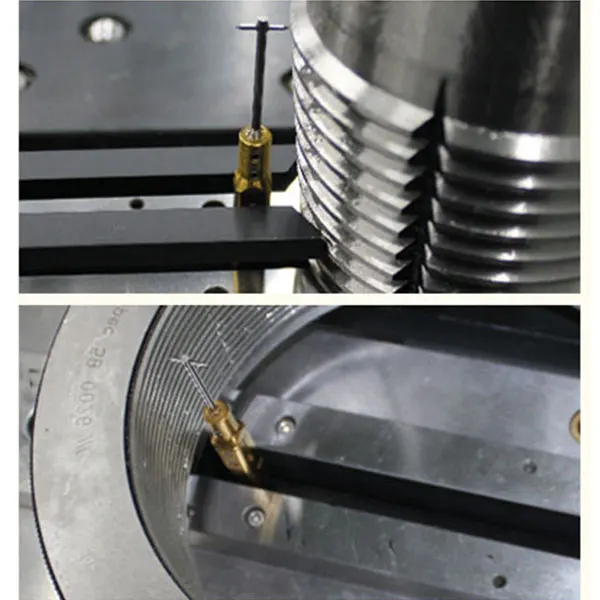

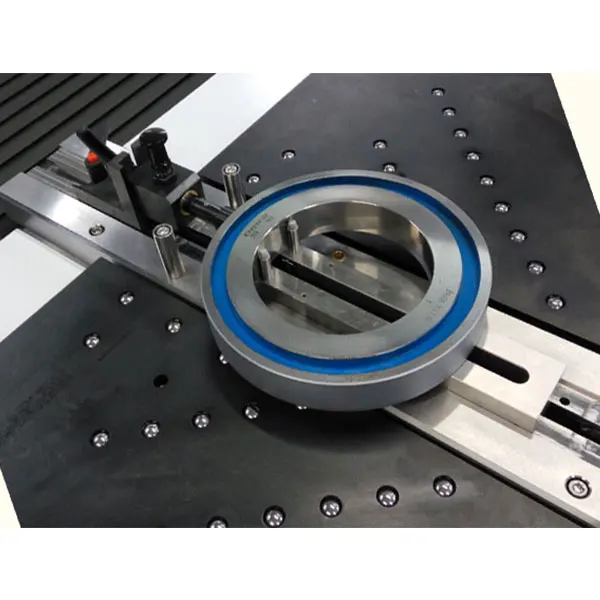

Applications