Product Description

Flash Measuring Machine - Large Travel Range Series VX3500/VX8500

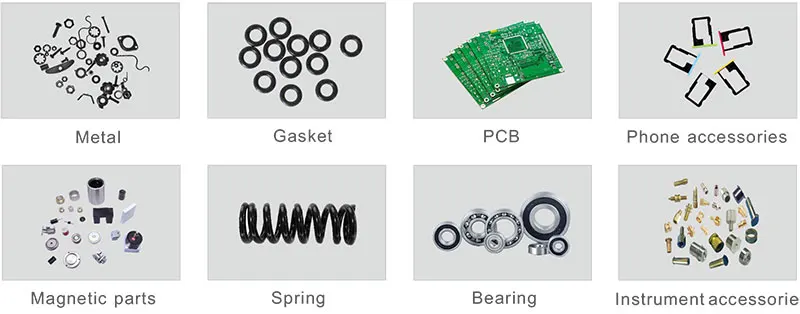

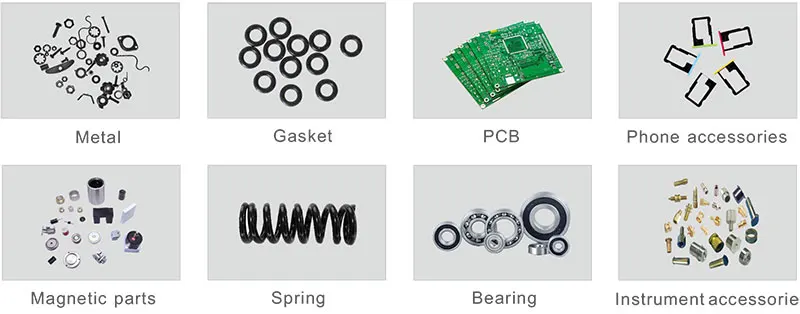

VX3500/8500 large travel range series flash measuring machine is based on the advanced one-key operation, large field of view and large depth of field, by building a traditional video measuring machine motion platform and large travel range stitching technology, giving full play to the dual advantages of flash measuring machine and video measuring machine, and achieving the large travel range and high efficiency of flash measurement. VX3500/VX8500 are suitable for precise dimensional measurement in the fields of machinery, electronics, molds, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical equipment, watches, cutting tools, Metrological Inspection(R gauge & sieve) etc.

Parameters

(*Note: Customized configuration & parts available for various requirements.)

| Model No. |

VX3500 |

VX8500 |

| Image Senor |

5M CMOS |

20M CMOS |

| Monitor |

24" LCD (XGA: 1920×1080) |

| Acceptance Lens |

Double Telecentric Lens |

| Light |

Ring Light |

Four-segment illumination(White Light/Green Light) |

| Back Light |

Telecentric transmission illumination(Green Light) |

| Coaxial Light |

LED parallel light |

| F.O.V. |

Wide Field(mm) |

500×400 (4 Angles R50) |

| High Precision(mm) |

430×330 |

| Repeatability of Image Meas. |

Wide Field |

Without Stitching*1 |

±1μm |

±1μm |

| With Stitching*2 |

±2μm |

±2μm |

| High Precision |

Without Stitching*1 |

±0.5μm |

±0.5μm |

| With Stitching*2 |

±1.5μm |

±1.5μm |

| Accuracy of Image Meas. |

Wide Field |

Without Stitching*1 |

±5μm |

±5μm |

| With Stitching*2 |

±(7+0.02L)μm |

±(5+0.02L)μm |

| High Precision |

Without Stitching*1 |

±2μm |

±1.5μm |

| With Stitching*2 |

±(4+0.02L)μm |

±(3+0.02L)μm |

Height Meas.

(Optical probe)

(Optional) |

Measuring Range(X*Y) |

300mm×300mm |

| Max Hole-Depth Ratio(H/φ) |

1.64 |

| Dia. of Beam |

Φ100μm (Φ18μm optional) |

| Resolution |

0.25μm |

| Z Non-movement |

Range(Z) |

±2mm |

| Accuracy |

±2μm |

| Z Movement |

Range(Z) |

200mm |

| Accuracy |

±(6+0.01H)μm, H is Z moving height in mm |

Horizontal Rotary Unit

(Optional) |

Rotation Angle |

Range 360°, Resolution 0.02° |

| Rotation Speed |

0.2~2rev/s |

| Max Diameter |

Φ60mm |

XY

Object Table |

X Travel Range |

410mm(Motorized) |

| Y Travel Range |

310mm(Motorized) |

| Loading Capacity |

20kg |

| Z Axis Travel Range |

200mm |

| Resolution |

0.1μm |

| Software |

VisionX |

| Size(LxWxH) |

900×1340×1600mm |

| Weight |

950kg |

| Power Supply |

AC100~240V, 50/60Hz, 10A, 2500W |

| Working Environment |

Temp.10 °C~35 °C, Humidity 20~80%, Vibration<0.002g, Less than 15Hz |

Remark:

*1 In the focus position, the environment temperature is +20 °C ± 1.0 °C;

*2 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 2 kg or less; L is the moving range of the table (mm).

Advantages

- Fast & Efficient

1. Place the object at will without any workholder.

2. Max 512 features at once time.

3. Quick and precise measurement for batch workpieces in CNC mode.

- Accurate & Consistent

1. Anybody can get the consistent results by one-key operation.

2. Automatic focusing: Avoid deviation because of different focusing.

3. Automatic feature identification: Consistent results from different measurement and different operators.

- Full functions & Automatic Reports

1. User-friendly software, powerful functions, simple operation.

2. In CNC mode, Quick and precise measurement for batch workpieces according to pre-set template by one-key operation.

3. Automatically output SPC analysis report, which contains statistical values (such as Ca, Cp, Cpk, Pp, Ppk, etc.) and control charts (such as mean and range charts, mean and standard deviation chart, median and range chart, single value and moving range chart).

- Easy Operation & Worry-free

1. Quick start without complex training.

2. Simple operation interface for anyone to program and measure.

3. Instant measurement of size deviation, one-key export reports of statistical analysis & measurement result.

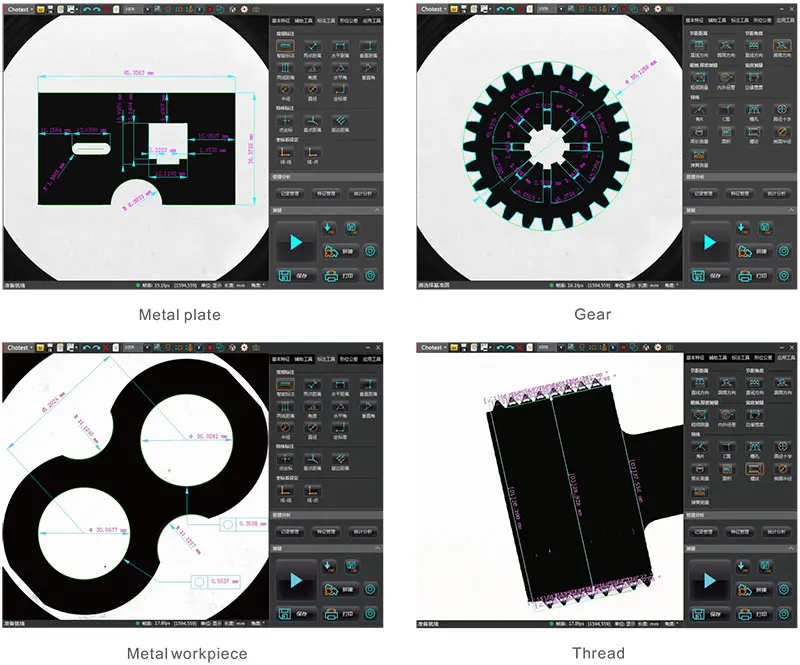

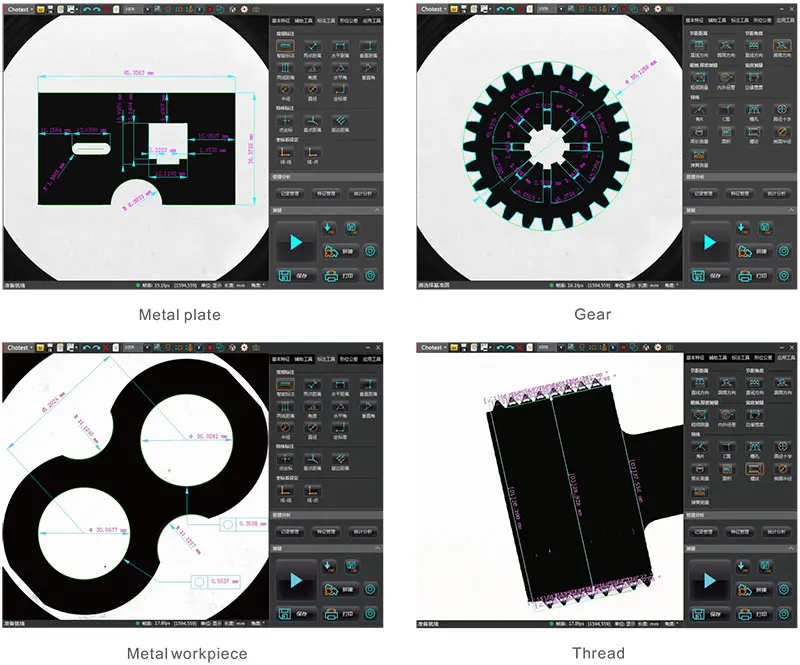

Functions

- Measurement

1. Measuring tools: scanning to extract edge points, multi-segment edge points, circular edge points, ellipse extraction, frame selection to extract contour lines, focus points, closest points, etc.

2. Measurable geometric quantities: point, line, circle (center coordinates, radius, diameter), arc, center, angle, distance, line width, hole position, hole diameter, number of holes, distance from hole to hole, distance from hole to edge, distance from arc center to hole, distance from arc center to edge, distance from arc high point to arc high point, distance from intersection to intersection, etc.

3. Construct features: intersection point, center point, extreme point, endpoint, two-point connection, parallel line, vertical line, tangent line, bisector, center line, line segment fusion, radius circle, three-line inscribed circle, two-line radius inscribed circle, etc.

4. Geometric tolerance: straightness, roundness, contour, position, flatness, symmetry, verticality, concentricity, parallelism and other geometric tolerance assessment.

5. Coordinate system: instrument coordinate system, point-line, two-point X, two-line and other workpiece coordinate systems; image registration coordinate system; coordinate system can be translated, rotated, and manually adjusted.

6. Quick tools: R angle, horizontal pitch, circular pitch, screen, slot, contour comparison, spring, O-ring and other special tools for quick measurement.

7. Supports batch setting of tolerances, scale level division, and color customization management.

- AI Technology

1. The AI model training interface is simple, the algorithm is powerful, the training ability is strong, and the training data is intuitive.

2. The AI measurement software can store images while measuring, continuously optimize and iterate the AI model, and is highly efficient.

3. It can solve traditional measurement pain points such as blurred boundaries, multiple boundaries, excessive burrs, and multiple edge interference.

4. Compared with traditional manual measurement, it is highly efficient and has good repeatability.

- Record Management

1. Centrally manage all measurement records.

2. CNC measurement supports barcode scanner input.

3. Query by workpiece model, workpiece name, inspection date, workpiece identification code, etc.

- Data Output

1. Can output Excel, Word, TXT reports.

2. Support import and export of AutoCAD files.

3. Support real-time output to excel templates, and can customize templates.

4. Output SPC analysis reports, can output statistical values (such as CA, PPK, CPK, PP, etc.) and control charts (such as mean and range charts, mean and standard deviation charts, median and range charts, single value and moving range charts).

5. Support Q-DAS transmission and support customized remote data docking.

Applications

Flash measuring machines are widely used in industry of machinery, electronics, mold, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical equipment, watches, tools, etc.