| Model: | RCYD-C80 |

|---|---|

| Brand: | EJETMAGNET |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Separation Equipment |

| Label: | Heavy Duty Overband , Iron Removal , Permanent Overband M |

| Price: |

US $34600

/ sets

|

| Min. Order: | 1 sets |

| Price Terms: | FOB CIF DAP DDU |

| Payment Terms: | TT / LC |

| Packing: | Export Packing |

| Last Online:30 Sep, 2025 |

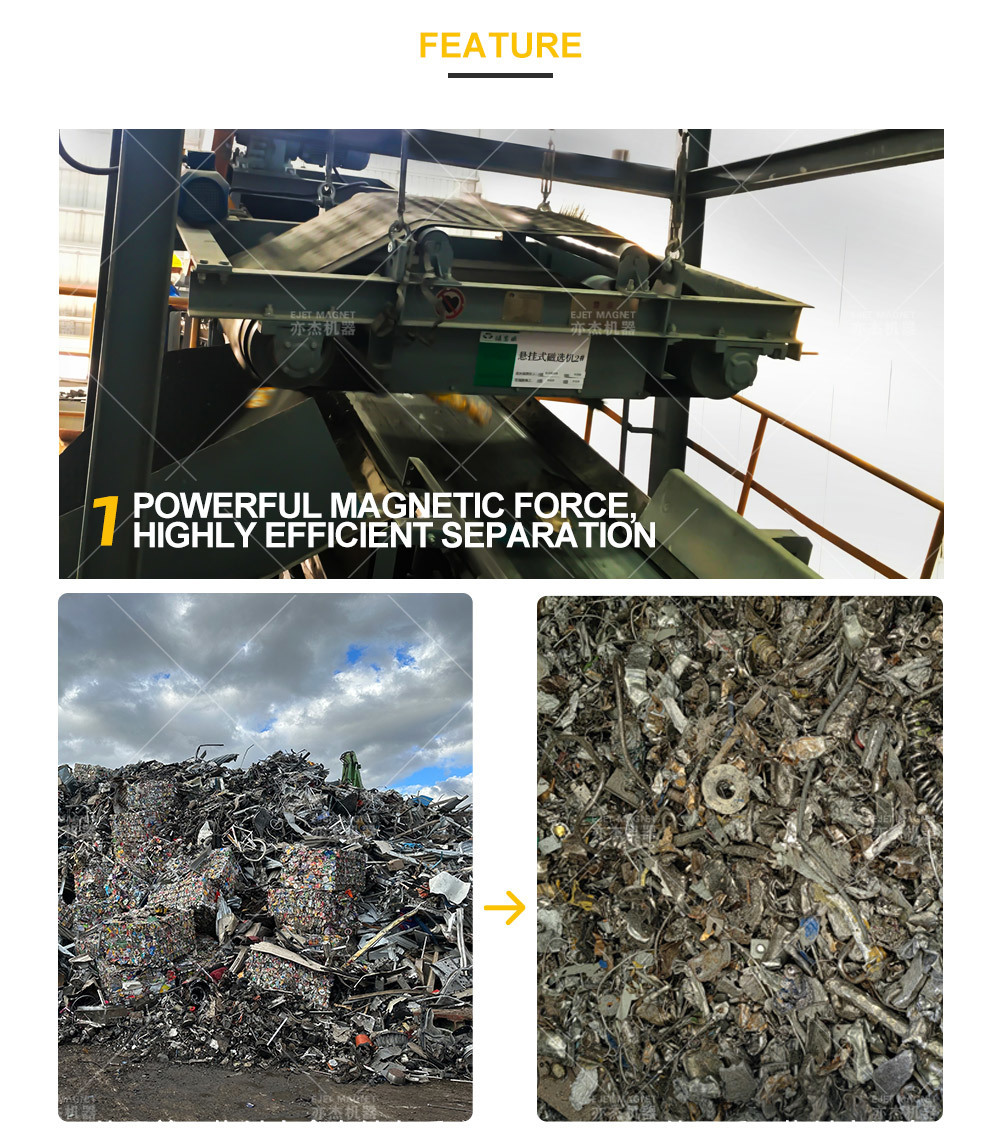

The RCYD-C Series Heavy-Duty Self-Cleaning Permanent Magnet is designed for high-intensity and high-load

operations. At its core, it uses high-performance neodymium iron boron (NdFeB) permanent magnets to generate

a powerful and deep magnetic field. This allows it to efficiently and automatically remove ferrous impurities-such

as iron chips, nails, screws, and even large iron pieces-from heavy material flows.

The system integrates a permanent magnetic circuit, a self-cleaning belt, and a geared motor into a fully automated

unit that captures, transports, and discharges tramp metal without manual intervention. It is an ideal solution for

protecting downstream equipment like crushers and grinders, while also improving end-product purity.

Features a computer-optimized magnetic circuit and high-performance rare-earth NdFeB

magnets. This combination delivers a high-intensity magnetic field with deep penetration,

ensuring efficient extraction of ferrous contaminants even from deep within material beds.

Built with a heavy-duty structure, reinforced protection for critical components,and a robust sprocket drive system.

It is engineered to withstand high-impact shocks from large, sharp ferrous metals, making it

perfectly suited for the toughest environments like mining and scrap metal recycling.

The RCYD-C model offers an optional stainless steel armored protection layer on the belt

The RCYD-C model offers an optional stainless steel armored protection layer on the belt

surface, effectively preventing cutting and tearing caused by sharp metals (such as rebars

and sheet metal edges), significantly extending the service life of the belt.

The entire system requires minimal electricity-only enough to power the conveyor belt.

The entire system requires minimal electricity-only enough to power the conveyor belt.

The permanent magnet core consumes zero energy, resulting in extremely low operating

costs and enabling reliable, continuous 24/7 operation.

The classic sprocket drive design offers superior impact resistance and operational stability

compared to traditional belt drives. With fewer maintenance points and simple installation,

it significantly reduces overall operating and maintenance costs.

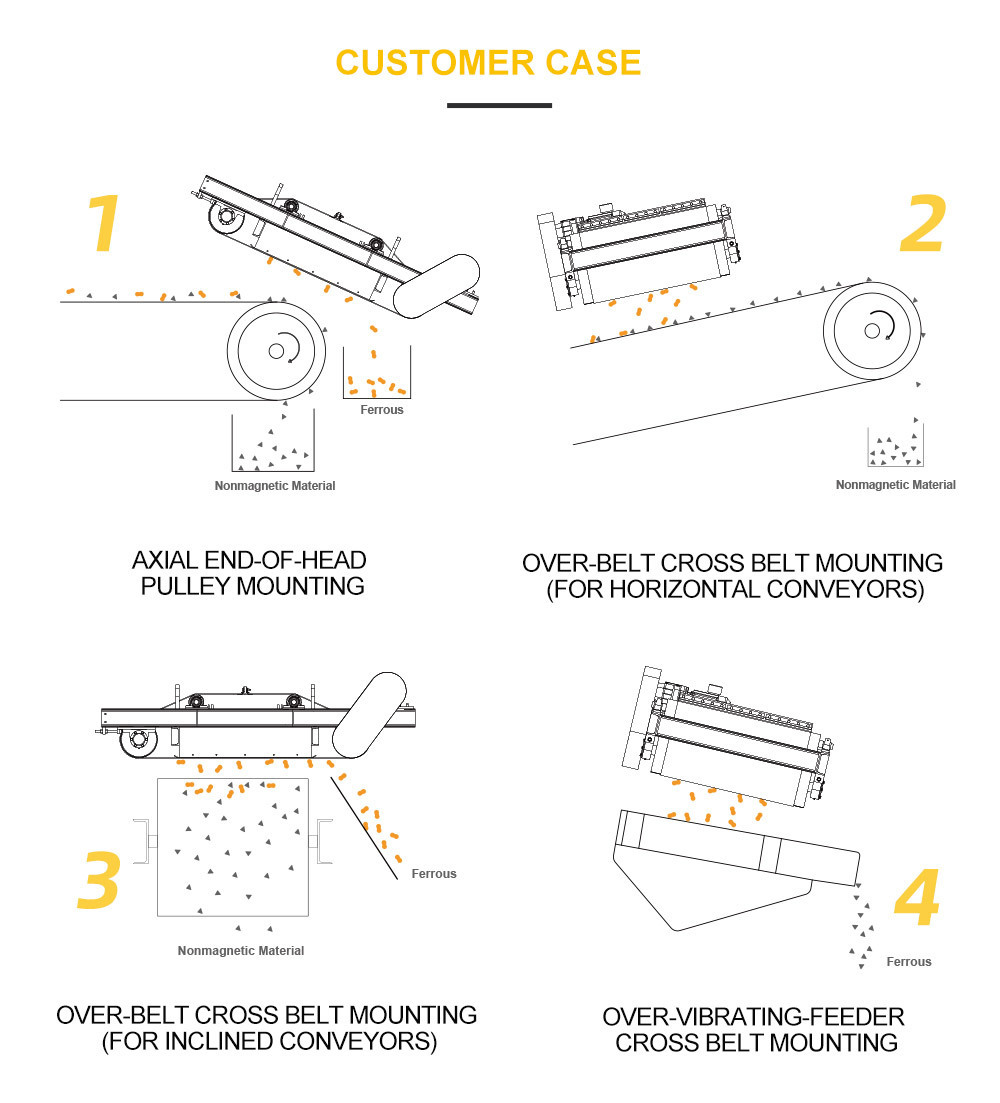

THE RCYD-C SERIES IS WIDELY USED FOR AUTOMATICALLY REMOVING FERROUS IMPURITIES FROM NON-MAGNETIC<br/>MATERIALS IN VARIOUS APPLICATIONS:

THE RCYD-C SERIES IS WIDELY USED FOR AUTOMATICALLY REMOVING FERROUS IMPURITIES FROM NON-MAGNETIC<br/>MATERIALS IN VARIOUS APPLICATIONS:

Resource Recovery: Scrap steel recycling plants, End-of-life vehicle (ELV) processing, Municipal solid waste (MSW) sorting.

Mining and Metallurgy: Raw material handling for Iron ore, Coal mines, Non-ferrous metal mines, sintering plants, and steel mills.

Building Materials: Purification of raw materials such as cement, quartz sand, granite, and gypsum.

Power and Chemical Industries: Coal conveying systems in coal-fired power plants and

biomass power plants, along with chemical raw material processing.Other Industries:

Wood shredding, Glass recycling, grain processing, and more.

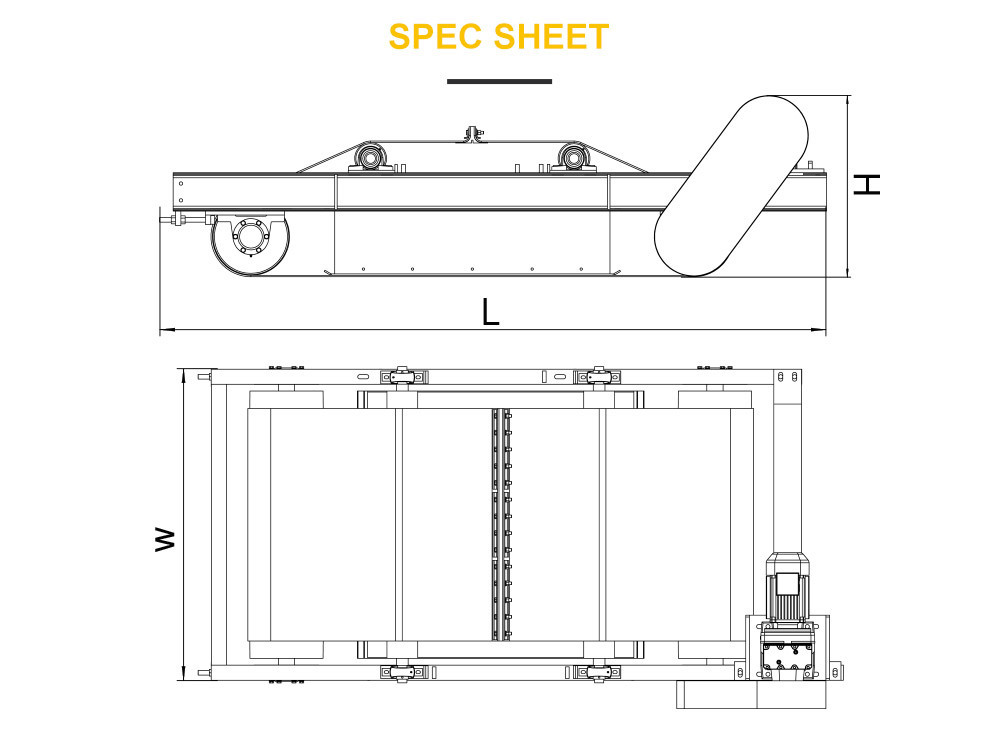

| Model | Dimensions(L*W*H)

mm |

Belt Width

(mm) |

Rated

Suspended Height (mm) |

Magnetic Field Strength

(GS) |

Motor

Power (kw) |

Weight

(kg) |

| RCYD-C50 | 1980*910*732 | 500 | 150 | ≥700 | 1.5 | 715 |

| RCYD-C65 | 2250*1060*732 | 650 | 200 | ≥700 | 1.5 | 890 |

| RCYD-C80 | 2350*1260*732 | 800 | 250 | ≥700 | 2.2 | 1295 |

| RCYD-C100 | 2720*1460*813 | 1000 | 300 | ≥700 | 3 | 1680 |

| RCYD-C120 | 2920*1720*878 | 1200 | 350 | ≥700 | 4 | 2325 |

| RCYD-C140 | 3120*1920*878 | 1400 | 400 | ≥700 | 4 | 3150 |

| RCYD-C160 | 3290*2120*878 | 1600 | 450 | ≥700 | 5.5 | 3530 |

| RCYD-C180 | 3570*2435*985 | 1800 | 500 | ≥700 | 7.5 | 5850 |

| RCYD-C200 | 3590*2630*1022 | 2000 | 550 | ≥700 | 7.5 | 6710 |

NOTE: THE ABOVE ARE PARTIAL MODELS, WE SUPPORT CUSTOM DESIGNS.

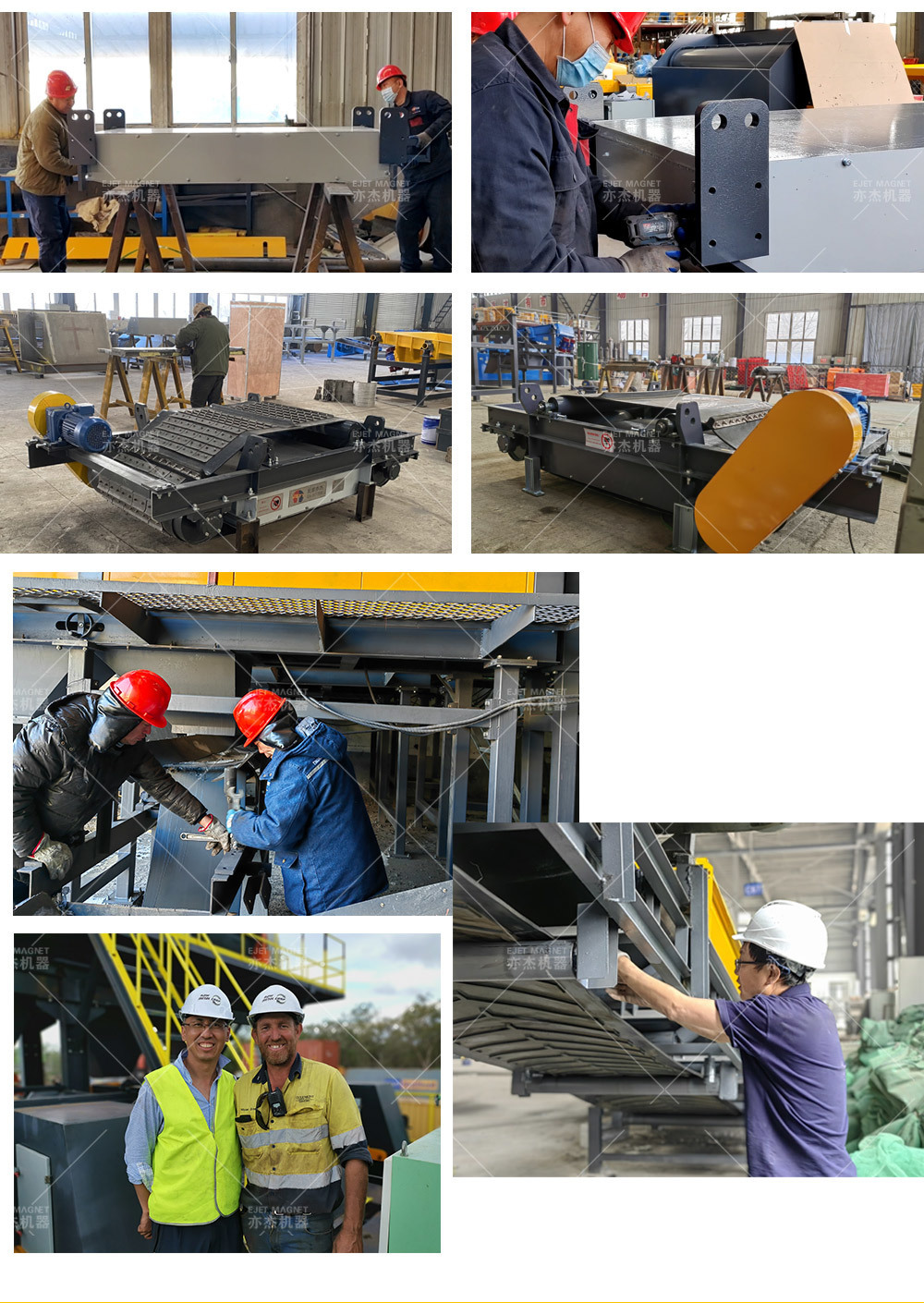

CUSTOMER CASE

CUSTOMER CASE

----

Case 1: Domestic Waste Recycling Industry

Equipment: 2 RCYD-C140 Suspended Over Vibrating Feeders

Results: The magnets effectively remove ferrous metals (such as cans, bottle caps, and iron

scraps) from household waste. This protects downstream crushing equipment from damage,

improves the purity of sorted materials, and allows efficient recovery of metal resources,

delivering both economic and environmental benefits.

Case 2: Waste Incineration Slag Industry

Equipment: 3 RCYD-C160 Units Mounted Above Belt Conveyors

Results: The systems efficiently extract and automatically recover iron-based metals(including wires, nails, and partially burnt packaging) from slag.

This significantly increases metal recovery rates, reduces wear on crushers, improves

the purity of slag-derived aggregates, and enhances the overall value of the end products.

Case 3: Construction Waste Recycling Line

Equipment: 9 RCYD-C180 Units Installed Above Conveyor Belts

Results: As part of a large-scale construction waste recycling system provided by

ejetmagnet Machinery, these magnetic separators reliably remove rebar, wires, fasteners,

and other ferrous metals. They protect key crushing equipment (such as jaw, impact, and

hammer crushers) from serious damage and unplanned downtime.

The high-purity recovered metal can be sold as recycled material providing strong

economic return while improving the quality and marketability of recycled aggregates

and building materials.

IS YOUR PRODUCTION LINE THREATENED BY MET AL IMPURITIES?

ARE YOU LOOKING FOR A RELIABLE, EFFICIENT, AND LOW-COST IRON REMOVAL SOLUTION?

Our engineers will recommend the most suitable RCYD-C model based on your material

characteristics, conveyor belt width, and working conditions, helping you enhanoe product

quality, safeguard critical equipment, and reduce operational costs.

EJET MAGNET'S COMMITMENT TO EXCELLENCE

~~~~~~

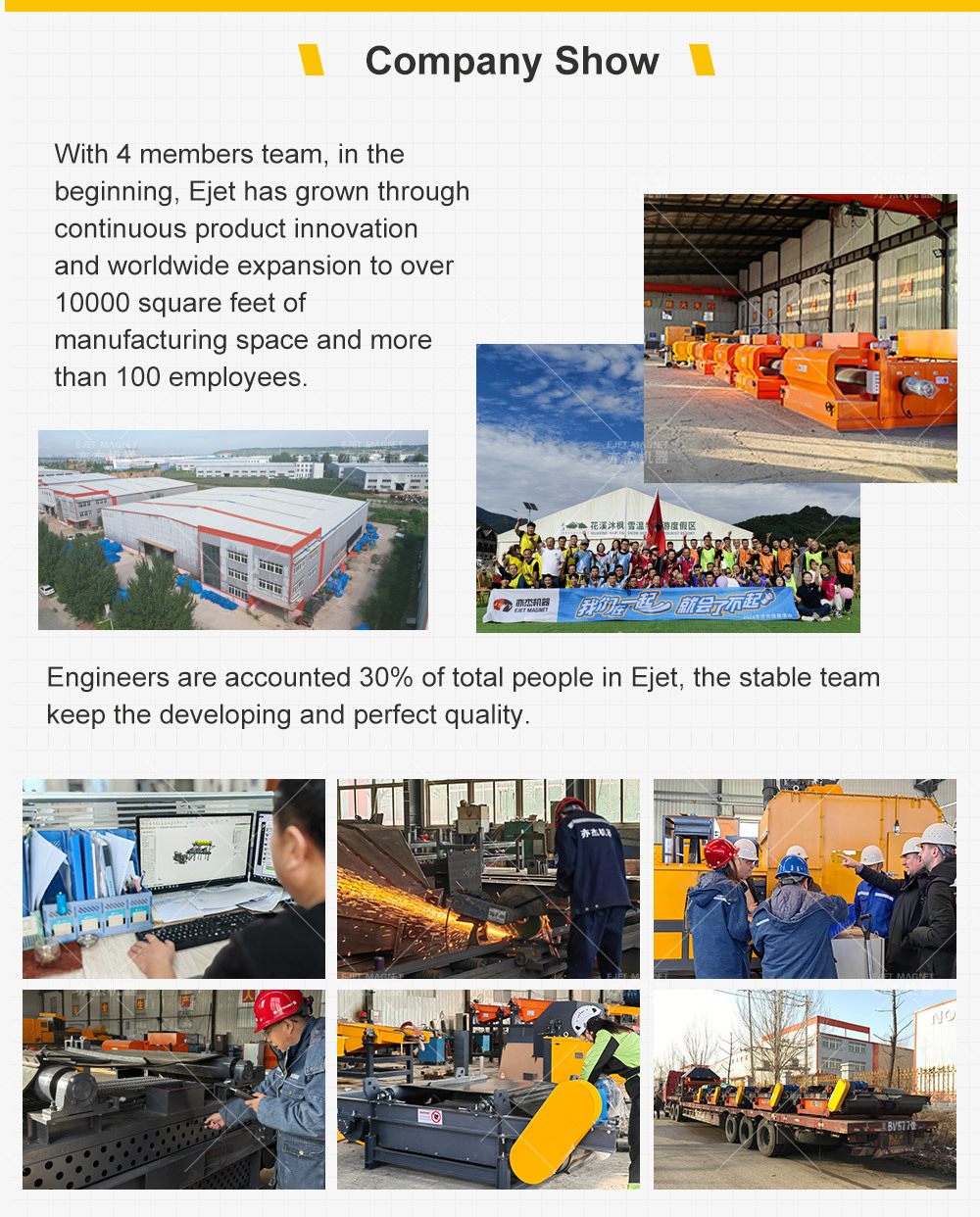

Since its establishment in 2006, Ejet Magnet has provided nearly 20 customized ASR

recycling solutions and equipment sets to the automotive recycling industry, with processing

capacities ranging from 3 to 30 tons per hour. The company's expertise in material

characteristics and composition has led to the development of highly efficient recycling lines

that maximize the recovery of valuable materials from ASR.

AFTER-SALES SERVICE AND SUPPORT

Ejet Magnet is committed to providing exceptional after-sales service, including:

WARRANTY:

year warranty for the entire machine, 3-year warranty for electromagnetic coils, and 8-year

warranty on magnetic performance for permanent magnet equipment.

RAPID RESPONSE:

A dedicated after-sales team promises to respond within 15 minutes and offers overseas

service if issues cannot be resolved remotely.

INSTALLATION AND TRAINING:

On-site installation, commissioning, and operator training are provided to ensure optimal

equipment performance and maintenance.

CONTINUOUS SUPPORT:

Ejet Magnet maintains comprehensive customer records and offers ongoing technical

assistance and training.

| Lead Time: | 30-90days upon the model and quantity |

|---|---|