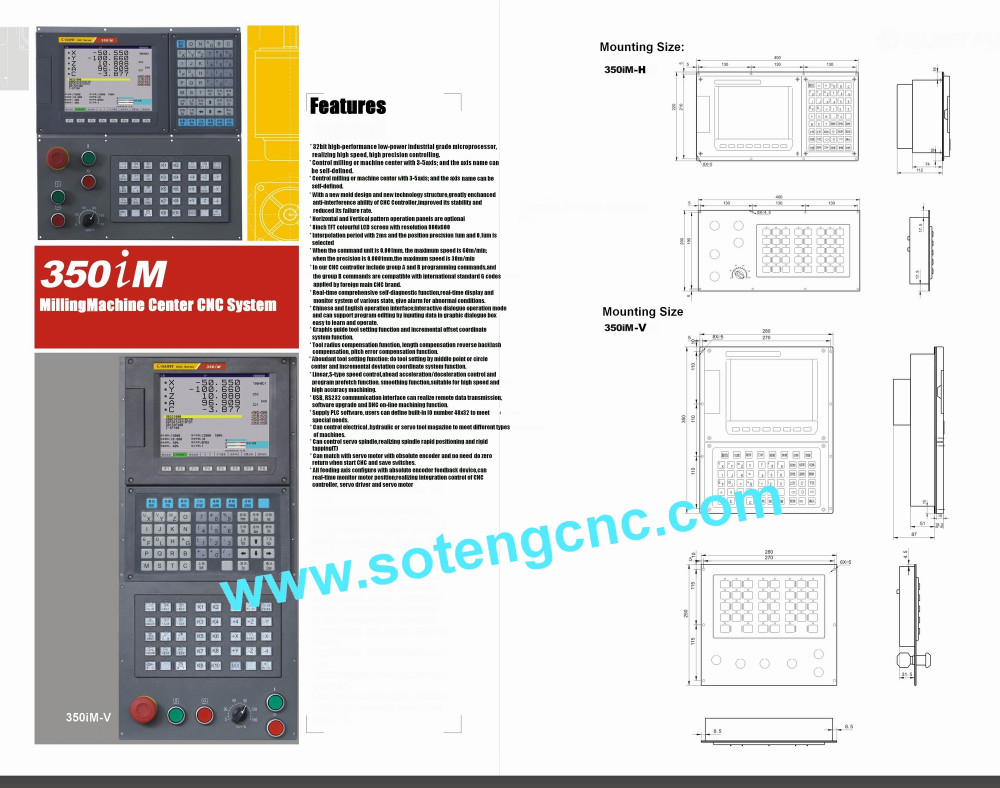

| Model: | GREAT-350iM-H |

|---|---|

| Brand: | GREAT-CNC |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Electronic Instrument / Automation & Control System |

| Label: | CNC System , CNC motor controller , CNC usb controller |

| Price: |

US $1400

/ pc

|

| Min. Order: | 1 pc |

| Last Online:09 Aug, 2017 |

This Price Include:

GREAT-350iM-H Operation panel 3Axis + subpanel + RIO board + 2pcs input board +2pcs output board and cables within 5meters =USD1500/set

Note:

1) our standard subpanel don't include MPG , customer need buy a handy pulser/handwheel to match with , if buy the handweel from us will charge USD140/pc

2) CNC accessaries include 2pcs input board and 2pcs output boards, our standard supply is normal type; we also supply output with relays,if customer need , please check with us to add the difference.

3) for our 350series CNC Controller, Horizontal and Vertical type are optional.

CNC Controller for Milling and Machine Center---GREAT-350iM-H

>Controllable axes: 3-5 axes

>Linkage axes: 3-5 axes linear, 2 axis arc linkage

>100MB user storage, 32bits 400MHz-800MHz ARM Industrial Processor

>8 inch TFT Colorful display with revolution 800X600

>Real-time and all-round self diagnosis

>Feed per minute and feed per revolution

>Linear, arc, spiral interpolation; Drilling, boring, tapping, etc. Fixed cycle macro commands

>Various interpolation commands and M, S, T function

>Max 99 tools management

>Chinese/English language

>Parameter package and software backup/upgrade

Absolute Superiority:

Speed:

>Max rapid traverse: 60m/min

>Max cutting speed: 20m/min

>Program preview: 1000 blocks

Precision:

>Screw pitch compensation, improving machining precision to the most

>2ms Interpolation period; control precision with 0.001mm and 0.0001mm are optional

Interface:

>Embeded PLC with I/O number 48x32, users can free to edit

>USB port, RS485 supply DNC function

>RS232 port supply DNC function by transmit rate 115200bit

>MPG on board or separate MPG are available

>Modular design : All I/O control via RIO, Input and output board; reduce interference and Minimize the failure rate; greatly improved CNC stability.

>Can match with motor with absolute encoder, no need zero return operation when power on machine.

>Dual channel control of spindle speed conversion, can control two spindle units and diverse tool magazine

Operation:

>Full-screen editing interface and foreground-background processing operation, which can do programming, parameter adjustment etc at same time 2D/3D graphic preview or simulating operation before machining, coordinates display, free shifting between 2D/3D graphic; Graphic can scale up/scale down, translate and rotate freely;

>Multilevel passward protection, such as program, parameter protection to convenient equipment management;

>Start machining at random block or tool number

>Compatible with popular foreign CNC system in instruction code and most program can run directly without amendment.