| Model: | BMB70 |

|---|---|

| Brand: | DYBM |

| Origin: | Made In China |

| Category: | Chemicals / Adhesives & Sealants |

| Label: | HPMC , Hydroxy Propyl , Methyl Cellulose |

| Price: |

US $4500

/ t

|

| Min. Order: | 1 t |

| Last Online:04 Aug, 2020 |

I. Hydroxypropyl methylcellulose(HPMC) is a type of nonionic cellulose ether made from natural high molecular materials through a series of chemical processes. With almost all properties of methyl cellulose (MC), it is the auxiliary agent of first choice in the production of top-quality construction materials. To satisfy the requirement of environment protection, Tasong brand product is developed and produced particularly for the construction material industry. With such favorable features as high water retention, good dispersancy, high degree of fineness, nice placeability and convenience to dissolve, it is applicable to the production of innovative construction materials like dry-powder mortar, waterproof putty powder (paste) for indoor and outdoor walls, binding agent, gap filler, interface finishing agent, water paint, self-leveling agent, etc. In the production of construction materials, cellulose ether is an indispensable additive. After HPMC is added, the following properties can be enhanced.

1. Water Retention: The water retention will be enhanced, which is helpful with such problems as cement or gypsum construction material drying too fast and poor hardening or cracking due to insufficient hydration.

2. Operationality: It can enhance the plasticity of mortar and improve the coating efficiency in construction projects.

3. Adhesivity: It can make mortar attach to base material better since the plasticity of mortar is enhanced.

4. Slip Resistance: It can prevent slipping problem between mortar and the base material in construction project as a result of its thickening effect.

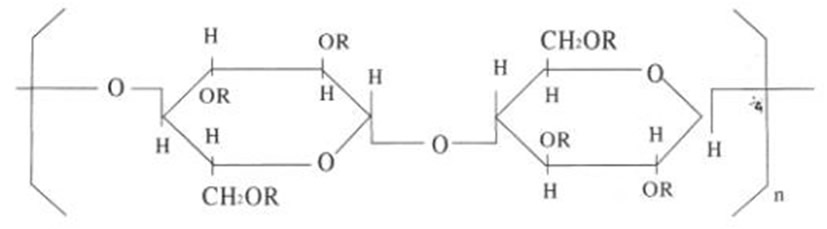

II.Molecular Composition and Structural Formula

Where n represents polymerisation degree, R is -H,-CH3 or CH2CHOHCH3.

III. Quality Indices and Technical Parameters

|

Items |

Product Model |

Methoxy % |

Hydroxypropyl % |

Viscosity Range |

Moisture Content % |

Ash Content % |

Degree of Fineness % |

Water-insoluble |

|

Low Viscosity |

DY-6000 |

26.5-31 |

4-7.5 |

5000-10000 |

≤6 |

≤2.0 |

≥99 |

≤0.5 |

|

DY-30000 |

26.5-31 |

4-7.5 |

25000-35000 |

≤6 |

≤2.0 |

≥99 |

≤0.5 |

|

|

Medium Viscosity |

DY-40000 |

26.5-31 |

4-7.5 |

35000-45000 |

≤6 |

≤2.0 |

≥99 |

≤0.5 |

|

DY-60000 |

26.5-31 |

4-7.5 |

55000-65000 |

≤6 |

≤2.0 |

≥99 |

≤0.5 |

|

|

DY-75000 |

26.5-31 |

4-7.5 |

65000-80000 |

≤6 |

≤2.0 |

≥99 |

≤0.5 |

|

|

High Viscosity |

DY-100000 |

26.5-31 |

4-7.5 |

85000-105000 |

≤6 |

≤2.0 |

≥99 |

≤0.5 |

|

DY-150000 |

26.5-31 |

4-7.5 |

120000-155000 |

≤6 |

≤2.0 |

≥99 |

≤0.5 |

IV. Physical and Chemical Properties

1.Appearance: HPMC is white or whitish fibrillar/granular and odorless powder

2.Dissolvability: HPMC is dissolvable in cold water and become clear or slightly cloudy liquid cement, but hardly in absolute ethyl alcohol, ethylether or propanone. In addition, HPMC is dissolvable in some organic solvents or some mixed solvents of water and organic solvent.

3.Granularity: Throughput rate: ≥98.5% for 100 mesh and up to 100% for 80 mesh.

4.Apparent Density: 0.30-0.70g/cm3, and density: 1.26-1.31g/cm3.

V. Product Features

1. Salt Resistance: HPMC is a type of nonionic cellulose ether rather than polyelectrolyte. Therefore, it is relatively stable in water where metal salt or organic electrolyte exists. However, excessive amount of electrolyte will lead to gelatinization and sedimentation.

2. Surface Activity: HPMC water solution has surface activity, which enables it to act as colloidal protective agent, emulsifying agent and dispersant agent.

3. Thermal Gelatinization: HPMC water solution will turn to opaque gel and settle when heated to certain temperature, but it will restore to the original solution when it is cooled down continually. The temperature leading to such gelatinization and sedimentation depends mainly on the types, concentration and heating rate of HPMC water solution.

4. PH Stability: The viscosity of HPMC water solution is hardly affected by acid or alkali, and it is relatively stable when pH value is in the range of 3.0 to 11.0.

5.Water Retention: HPMC is a type of high-efficiency water retention agent that is widely used in the production of ceramics, construction materials and many other fields.

6. Adhesivity: HPMC, as a type of high-performance binding agent, is applicable to the production of coloring pigments, tobacco products, ceramic products and papermaking.

VI. Dissolving Methods:

Coacervation will happen before dissolving if HPMC product is directly charged into water. However, it is very slow and difficult to dissolve in this way. Three dissolving methods are recommended here below for users to choose based on the specific applications:

1.Hot Water Method: Add water into a vessel to 1/3 or 2/3 of the required level before heating it up over 80 C. Since HPMC is indissolvable in hot water, HPMC will be dispersed in hot water homogeneously. Then add cold water or ice water to the hot water slurry to the expected level. Keep agitating to cool the mixture down.

2.Powder Mixing Method: Mix HPMC powder up with other powdery material(s) of the same or higher amount in dry state for full dispersal. Then add water into the mixture for dissolving. HPMC will be dissolvable instead of coacervation.

3.Organic-solvent Humidification Method: Disperse or humidify HPMC with organic solvent such as alcohol, ethanediol or oil before add in water.Then HPMC will go dissolvable successfully.

Note: The surface-treated HPMC, after humidified with cold water, will become viscous if add ammonia water or alkaline water for pH value within 8 to 10.

VII. Main Applications

HPMC may serve as thickening agent, dispersant agent, emulsifying agent or film-forming agent, and its industrialized products may be applicable to the production of daily chemicals, synthetic resin, construction and coating materials.

1.Suspension Polymerization:

In the production of synthetic resin such as polyvinyl chloride (PVC), polyvinylidene chloride (PVDC) and other copolymerisate, suspension polymerization is the most used and it requires to keep hydrophobic monomers to suspend in the water. HPMC product has excellent surface activity as a type of water-soluble polymer. In addition, it plays the role of colloidal protectant that it can delay the coacervation of particles. Furthermore, although HPMC is a type of water-soluble polymer, it is somewhat dissolvable in hydrophobic monomers and can enhance the monomer porosity for production of polymerizing particles, thus, it may render polymer good capacity for removal of residual monomers and absorption of plasticizer.

2.It is applicable to the production of following products in the recipe of construction materials.

1) Waterproof putty powder

2) Cement sand mortar

3) Cement base brick/tile and the bonding between tile and base brick

4) Plaster for gypsum board base

5) Cement-based structural plaster.