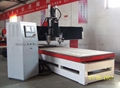

| Model: | FC-1325AT |

|---|---|

| Brand: | FANCH |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Engraving & Etching Machine |

| Label: | plasma cutter , cnc machine plasma , plasma cutting |

| Price: |

US $7500

/ set

|

| Min. Order: | 1 set |

| Last Online:24 Dec, 2015 |

Scope of application:

CNC plasma cutting machine is a atomatic and high efficiency cutting equipment. It is widely used in all kinds of carbon materials, stainness steel, iron sheet, aluminum sheet, galvanized sheet, titanium plate and nonferrous metal precision sheet metal cutting.

Technology Parameter:

Model | FC-1325AT |

Process area | |

Proess thickness | 0.5 |

Cutter speed | 100 |

power | 8.5kw |

Input voltage | 3(phase)380V |

Power frequency | 50HZ |

Torch (plasma power) | Domestic/ American Hypertherm optional |

Plasma current | |

File transfer method | USB connection |

Work mode | Untouched arc striking |

Control system | DSP / Start optional |

Drive motor | Stepping motor/ Servo optional |

Transmission | Pinion and rack transmission |

Structure | Seamless welding steel structure |

*parameter could be customised.

Features of machine:

1.The beam uses light structural design, with good rigidity structure, light deadweight and small movement inertia.

2.The gantry structure, Y axis uses dual-motor dual-driven system, X, Y, Z axis all use dual-straight rail that make the machine driving smoothly with high-precision.

3.Aiming at cutting three dimension LED character, trough metal panels and floor cutting, the accuracy can reach good indicators. If it equipped with United States HYPERTHERM plasma source the machine can reach threshold.

4.Equipped with other advertise equipment (blister machine, engraving machine), forming the advertising word processing pipeline. Completely solve the traditional manual processing methods. Improve the efficiency of several times.

5.Cutting mouth is small, tidy, and avoid a second dressing processing.

6.It can apply to iron sheet, the aluminum sheet, the galvanized sheet, hundred steel plates , metal plates and so on.

7.High cutting speed, high precision, and low cost.

8.The numerical control system disposes high, the automatic striking arc, the performance is stable.