Product Description

The unit applies planetary speed reducer design, which produces low noise, high mechanical efficiency and save the power consumption and minimize the spaces required for the equipment.

| |

|

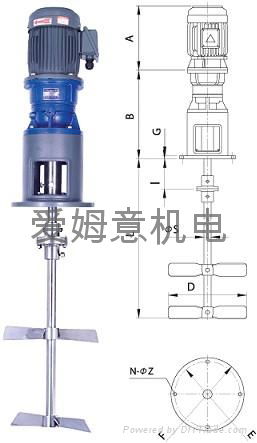

A |

B |

E |

F |

G |

I |

N-ØZ |

| Type |

Motor |

B1 |

B2 |

B3 |

| E24-02 |

1/4 HP |

225 |

315 |

345 |

375 |

200 |

220 |

17 |

80 |

4- Ø 11 |

| E24-05 |

1/2 HP |

248 |

315 |

345 |

375 |

200 |

220 |

17 |

80 |

4- Ø 11 |

| E32-02 |

1/4 HP |

225 |

409 |

443 |

477 |

250 |

280 |

18 |

100 |

4- Ø 13 |

| E32-05 |

1/2 HP |

248 |

409 |

443 |

477 |

250 |

280 |

18 |

100 |

4- Ø 13 |

| E32-10 |

1 HP |

242 |

409 |

443 |

477 |

250 |

280 |

18 |

100 |

4- Ø 13 |

| E32-20 |

2 HP |

322 |

409 |

443 |

477 |

250 |

280 |

18 |

100 |

4- Ø 13 |

| E38-05 |

1/2 HP |

248 |

- |

540 |

574 |

290 |

330 |

20 |

150 |

6- Ø 13 |

| E38-10 |

1 HP |

242 |

509 |

540 |

574 |

290 |

330 |

20 |

150 |

6- Ø 13 |

| E38-20 |

2 HP |

322 |

509 |

540 |

574 |

290 |

330 |

20 |

150 |

6- Ø 13 |

| E38-30 |

3 HP |

315 |

512 |

558 |

584 |

290 |

330 |

20 |

150 |

6- Ø 13 |

| E38-50 |

5 HP |

371 |

512 |

558 |

- |

290 |

330 |

20 |

150 |

6- Ø 13 |

| E38-75 |

7.5 HP |

374 |

527 |

- |

- |

290 |

330 |

20 |

150 |

6- Ø 13 |

| E50-10 |

1 HP |

242 |

522 |

564 |

594 |

300 |

350 |

22 |

200 |

6- Ø 16 |

| E50-20 |

2 HP |

322 |

522 |

564 |

594 |

300 |

350 |

22 |

200 |

6- Ø 16 |

| E50-30 |

3 HP |

315 |

524 |

566 |

604 |

300 |

350 |

22 |

200 |

6- Ø 16 |

| E50-50 |

5 HP |

371 |

524 |

566 |

604 |

300 |

350 |

22 |

200 |

6- Ø 16 |

| E50-75 |

7.5 HP |

374 |

539 |

581 |

- |

300 |

350 |

22 |

200 |

6- Ø 16 |

| E50-100 |

10 HP |

412 |

539 |

581 |

- |

300 |

350 |

22 |

200 |

6- Ø 16 |

|

|

Model number, rotating speed, mixing shaft, blades

| |

|

(rpm) |

( Ref. ) |

| Type |

Stage |

60Hz |

50Hz |

Ø S |

L |

D |

| E-24 |

B1 |

490-354-303-242-187 |

406-294-251-205-155 |

25 Ø

30 Ø |

1500 |

150~336 |

| B2 |

137-99-85-69-61-50-38-26-20 |

114-82-70-57-51-41-31-22-17 |

2200 |

330~500 |

| B3 |

19-15-12-8 |

16-12-10-6 |

2500 |

360~600 |

| E-32 |

B1 |

503-411-303-243 |

417-340-251-201 |

30 Ø

35 Ø

40 Ø |

2200 |

200~450 |

| B2 |

145-118-96-87-70-57-53-42-34 |

120-98-80-72-58-47-44-35-28 |

2800 |

250~600 |

| B3 |

28-20-15-12-8 |

23-17-13-10-7 |

3200 |

400~800 |

| E-38 |

B1 |

503-411-303-243 |

417-340-251-201 |

40 Ø

45 Ø

50 Ø |

2500 |

300~550 |

| B2 |

145-118-96-87-70-57-53-42-34 |

120-98-80-72-58-47-44-35-28 |

3200 |

400~700 |

| B3 |

28-20-15-12-8 |

23-17-13-10-7 |

3500 |

500~1000 |

| E-50 |

B1 |

503-411-303-243 |

417-340-251-201 |

45 Ø

50 Ø

55 Ø |

3000 |

300~650 |

| B2 |

145-118-96-87-70-57-53-42-34 |

120-98-80-72-58-47-44-35-28 |

3500 |

450~1000 |

| B3 |

28-20-15-12-8 |

23-17-13-10-7 |

3800 |

600~1200 |

|

1. Blade curvature (D), shaft diameter (S), shaft length (L) are all reference dimensions. Actual selection should depend on the conditions including dimensions of the tank, stirring objective, rotating speed, viscosity, blade configuration etc.

2. Mixing blades are mainly the blade paddle type. The portions of the shaft and blades that directly contact the liquid are made of SUS304. If other specific material or coating and painting are needed, please contact our company for details. |

Product Image

Img 1

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,