All kinds of mechanical workpiece supersonic spraying smooth

Product Description

All kinds of mechanical workpiece supersonic spraying smooth mechanical equipment factory repair all kinds of mechanical equipment wear and tear of spare parts, strain, corrosion, peeling, such as: crankshaft, motor shaft, gear shaft, valves, bearing, mold, guide rail, etc. Various kinds of cylindrical, hole, plane class wear. But the door does not remove the field construction spraying hard alloy, stainless steel, pottery and porcelain, babbitt, zinc aluminum, copper lead molybdenum wait for all sorts of function coating. The functional coating company processing coating types: A, resistant to wear A thermal spraying technology application's largest fields, this kind of coating is mainly: (1) resistance to adhesive wear or scratches special one typical coating for cobalt base tungsten carbide, chromium carbide/nickel chromium coating. (2) wear particle wear a special typical coating for cobalt base alloy, from fusion gold mixed molybdenum, chrome oxide coating. (3) resistance to fretting a special typical coating for alumina/titanium dioxide coating. (4) resistant to cavitation erosion wear a special typical coating for aluminum bronze coating. (5) resistance to erosion wear a special typical coating for alumina/titanium dioxide, alumina coating. B, resistance to high temperature and oxidation a this kind of coating resistance to chemical or physical decomposition, improve the parts of high temperature performance, this kind of coating is mainly: (1) thermal barrier coating a typical coating for yttrium oxide do stabilizing treatment of zirconia coating. (2) resistance to high temperature oxidation coating a typical coating for nickel/chromium coating. (3) heat resisting corrosion coating a typical coating for nickel/chromium coating. C, anticorrosion coating a coating system for: spraying layer + sealing material. D, conductive coating or insulation coating by this kind of coating and divide it is the following kinds: (1) conductive coating a namely copper coating. (2) insulation coating a alumina coating. (3) shielding coating a resistance to electromagnetic interference (EMI) or high frequency interference (RFI) that copper coating. E, restore size coating a this kind of coating is mainly used to repair for wear or processing out-of-tolerance parts, on the coating material and choice depends on the components of the use requirement. F, clearance control coating a this kind of coating provide close seal clearance, improve equipment performance and operation efficiency, and mating part contact, coating priority controlled wear, the typical coating for nickel/graphite, polyester aluminum mixture, aluminum/graphite coating

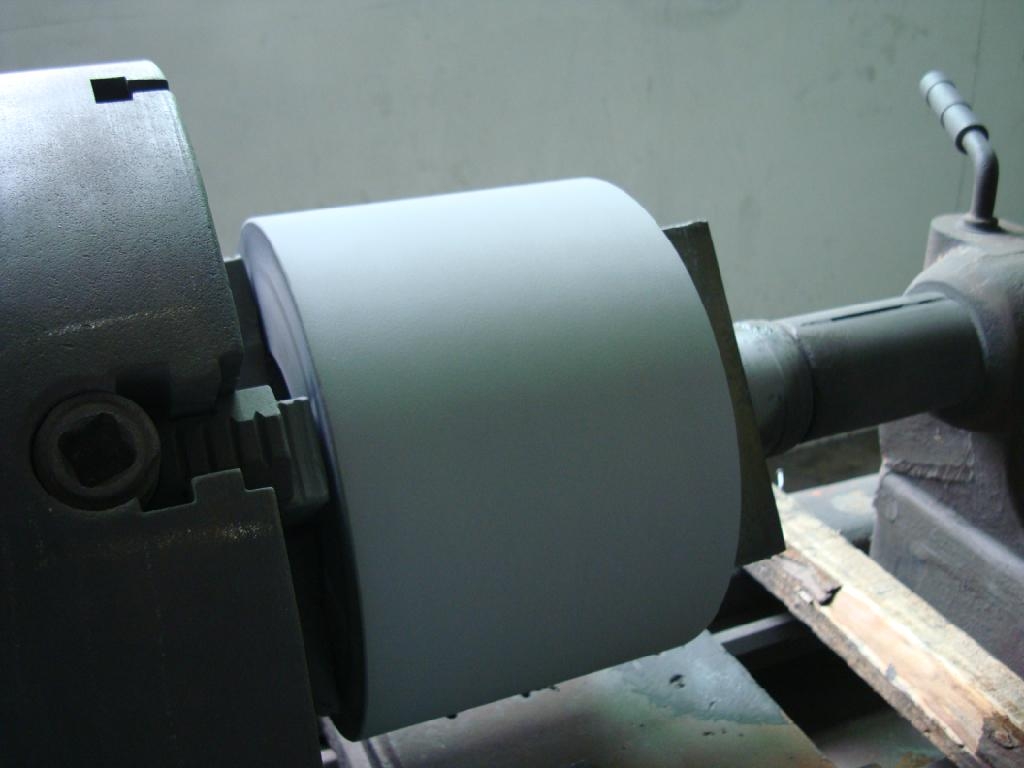

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,