XC-203 Aiziridine Modified isocyanate Crosslinker

Product Description

DESCRIPTION

XC-203 is a type of aziridine modified isocyanate crosslinker, it is different with the normal blocked isocyanates, it is not reactive by NCO from unblocking as the normal isocyanates, in fact, it is reactive by the aziridine cycle-opening; Commercial XC-203 product is a colorless to pale yellowish clear liquid , mainly be used as additive in the system of Nylon-66 for improving bonding strength of various adhesives; it also can be used in various fields when strong bonding effect is required in the basic system of acrylic and polyurethane water-borne resins.

SPECIFICATION

Appearance: colorless to pale yellowish liquid;

Toalal Solid (w/w): 70.0%;

CAS NO.:NV;

Specific Gravity at 25°C: 1.0g/ml;

Viscosity, cp at 25°C: 2000-4000.

APPLICATIONAS

It is mainly used in the system of Nylon-66, are also expected to possess excellent chemical resistance and high modulus;

In the system water based printed paste, can improve the abrasion resistance and gloss finish, not formaldehyde appear;

In water based acrylic resin and polyurethane latex, increase cohesive strength after heat treatment;

In any water based latex containing –COOH, -OH, -NH2, improves the resin strength and abrasion resistance, after dry and heat treatment;

In water based cotton & terylene latex, increases water and oil resistance;

In vinyl coatings to reduce plasticizer migration and improve stain resistance;

In water based concrete sealers to improve abrasion resistance

Generally, in any water based resins, improve the water, detergent, solvent, chemical resistance and abrasion resistance, after heat treatment formulation.

TYPICAL APPLICATION CONDITIONS

Method of Addition: XC-203 is added to finish formulated coating systems just prior to use. The crosslinker is added, slowly and with good agitation, directly to the formulated coating system. It can be added neat or in solution. If added in solution, a solvent without an active H+ should be used.

Addition Levels. The level of crosslinker to add to the formulated system will depend on the coating system and the desired properties of the coating film. Most applications find use levels between 1% and 3% based on resin solids. Higher levels, such as 5%, may yield higher solvent resistance and adhesion properties.

pH of the Formulated System. An aqueous system pH of 9.0-9.5, at the time of crosslinker addition, most often produces the optimum results. A lower pH may cause the aziridine to react prematurely in the pot.

Pot Life: An aqueous system containing a low boiling (volatile) amine, such as ammonia or triethylamine, has a pot life of about 18-36 hours. If use is extended beyond this time, there will be a loss of aziridine functionality. This loss can be replenished, without a negative effect on film properties, by adding more of the crosslinker.

PACKAGE & STORAGE

Available 4*5Kgs plastic pails, and 25Kgs steel drums with inner plastic pails. Store in a cool, dry, dark place. If stored under conditions of excessive heat for extended periods the material may discolour, deteriorate and gel.

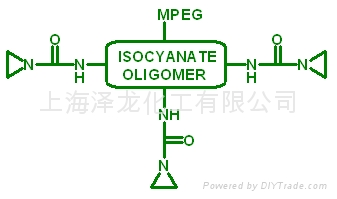

Product Image

Img 1

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,